Technology for complexing, crystallizing, separating and purifying metacresol

A technology for crystallization separation and m-cresol, which is applied in the technical field of separation and purification of m-cresol by complex crystallization method, and can solve problems such as not mentioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

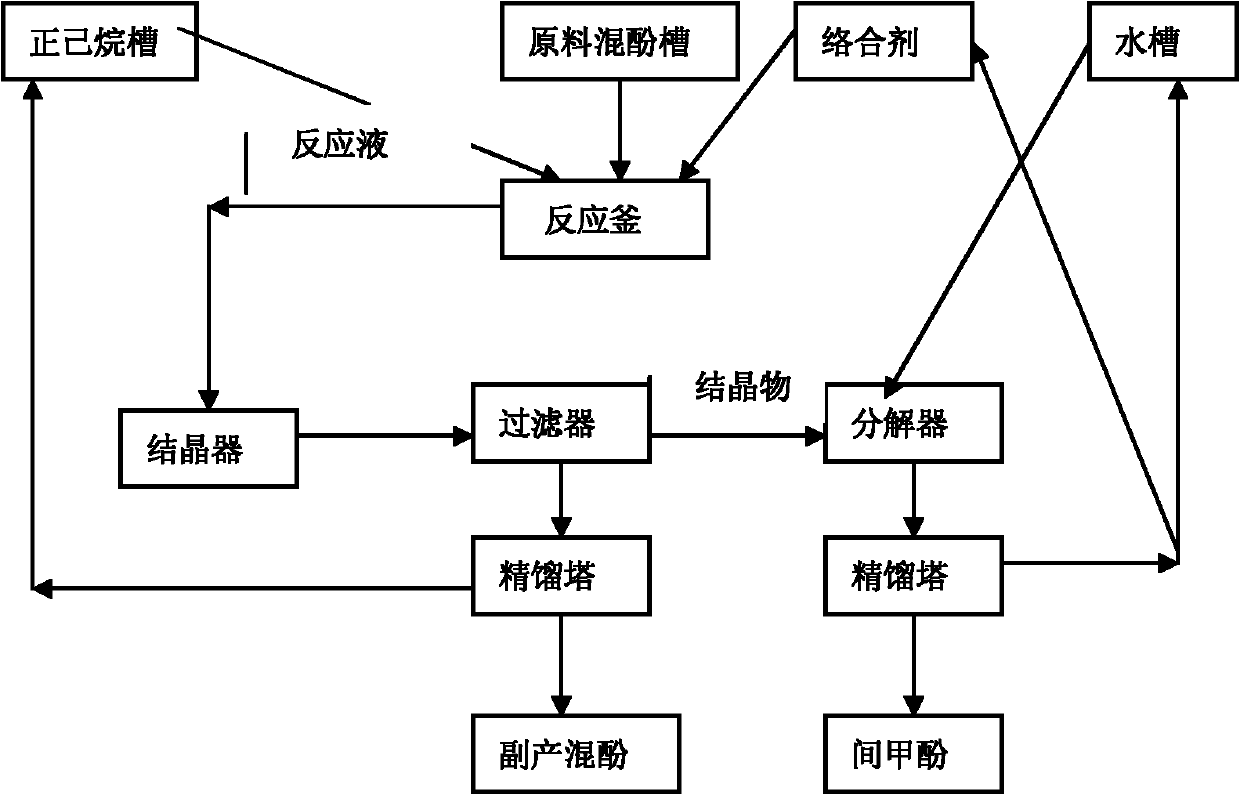

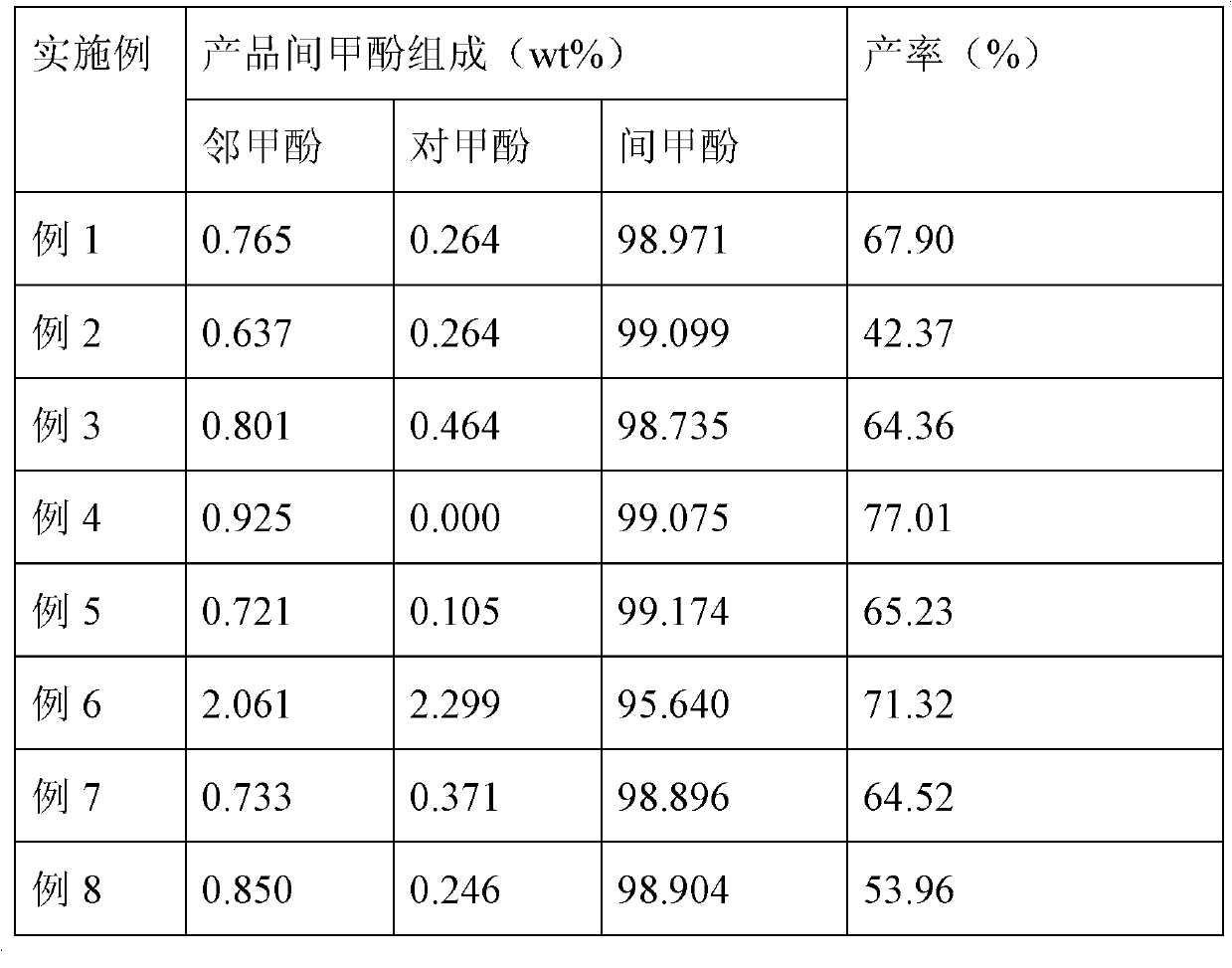

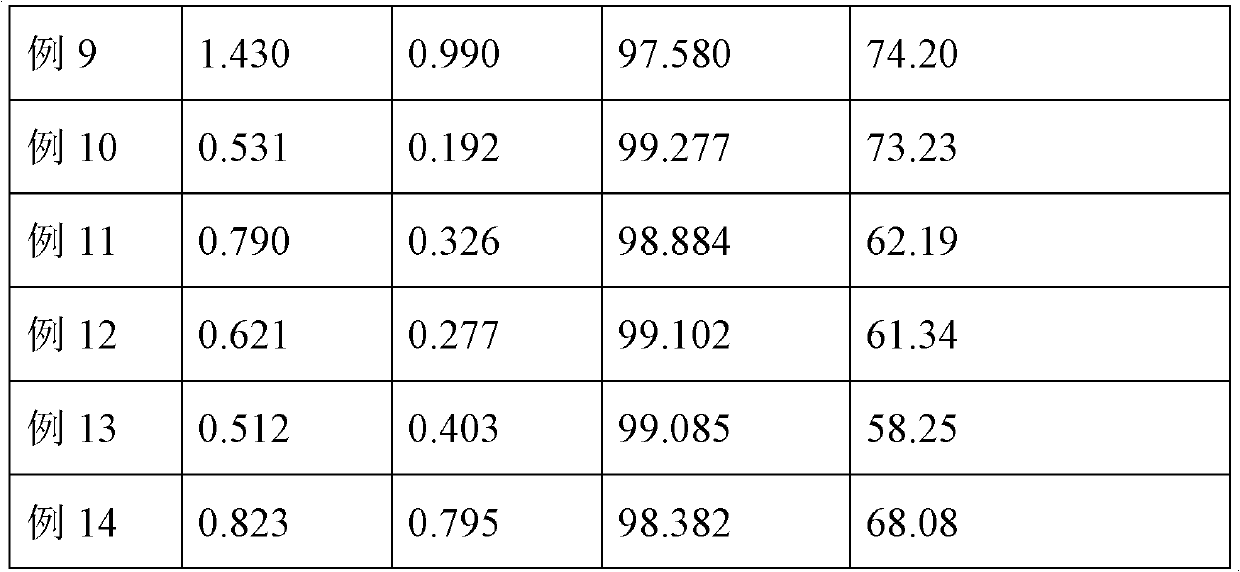

[0016] The present invention will now be described in detail with reference to the accompanying drawings. Accompanying drawing is the process flow diagram of complex crystallization separation m-cresol. The raw material mixed phenol is stored in the raw material mixed phenol tank. The raw material mixed phenol used in the reaction is mixed phenol isomer mainly containing o-cresol (10.907wt%), p-cresol (34.276wt%), m-cresol (53.176wt%), xylenol (1.641%). The raw material mixed phenol enters the reaction kettle, and at the same time, urea is also put into the reaction kettle. The molar ratio of urea and m-cresol is 1.0-1.8. In the reactor, the temperature was raised to 85-105°C for 40-80min. After cooling, add n-hexane in the n-hexane tank at a temperature of 60°C, and the volume ratio of n-hexane to m-cresol is 1-3. After that, the reaction liquid enters the crystallizer. Crystallize at minus 10-20°C for 1-2 hours to complete the crystallization operation. Then the crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com