Method for directly separating phenols from coal pyrolytic oil

A technology of pyrolysis of phenolic substances and coal, applied in chemical instruments and methods, preparation of organic compounds, liquid solution solvent extraction, etc., can solve the problem of low extraction rate of phenols, achieve reduced production costs, mild conditions, and avoid strong The effect of acid-base corrosion equipment and phenolic wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

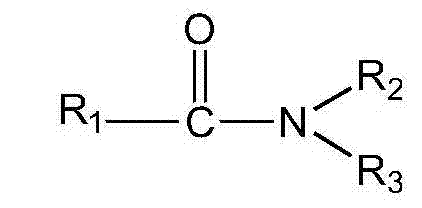

Method used

Image

Examples

Embodiment 1

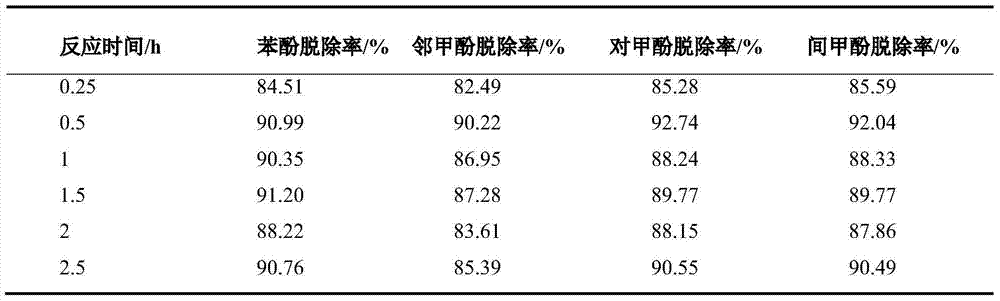

[0024] m-cresol was dissolved in n-hexane to prepare model oil solution, the concentration was 200.2g / L, and the amides were nicotinamide (C 6 h 6 N 2 O), the molar ratio of nicotinamide to m-cresol is 0.4:1, the separation temperature is 30°C, and the reaction time is 30min.

[0025] At 30°C, 4.523g of nicotinamide was added to 50ml of model oil solution, stirred for 30 minutes, and left to stand for 10 minutes. The volume of the upper oil phase and the concentration of m-cresol in it were measured by GC. The removal rate of m-cresol was 92.00%. Remove the upper oil phase, add 50mL stripping agent diethyl ether into the lower eutectic phase, stir for 20min, let stand for 10min, perform suction filtration, put the solid obtained by vacuum filtration into a vacuum drying oven at 80°C for 1h, weigh and calculate the recovery rate . The above process was repeated 4 times, the removal rate of m-cresol was 95.32%, and the recovery rate of nicotinamide in 4 cycles was 90.15%.

Embodiment 2

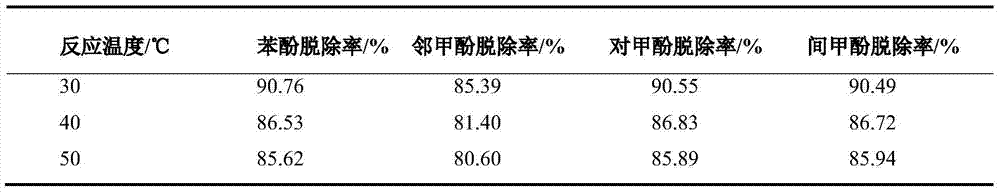

[0027] Phenol was dissolved in n-hexane to prepare simulated oil solution, the concentration was 20.36g / L, the amide substance was urea, the molar ratio of urea to phenol was 1:1, the separation temperature was 30°C, and the stirring time was 30min.

[0028] At 30°C, 0.4680g urea was added to 30mL model oil solution, stirred for 30min and then allowed to stand for 5min to measure the volume and phenol content of the upper oil phase. After suction filtration and drying, the mass of the complex was 0.8133g, and the removal rate of phenol was 85.06 %.

[0029] Remove the upper oil phase, add 20ml of diethyl ether to the dried complex, stir for 15min and let stand for 5min, vacuum filter the obtained solid into a vacuum drying oven at 70°C for 1h, weigh and calculate the recovery. The above process was repeated three times, the removal rate of phenol was 85.00%, and the recovery rate of urea in three cycles was 85.50%.

Embodiment 3

[0031] m-cresol was dissolved in n-hexane to prepare model oil solution, the concentration was 210.0g / L, and the amides were pyrazinamide (C 5 h 5 N 3 O), the molar ratio of pyrazinamide and m-cresol is 0.5:1, the separation temperature is 35°C, and the reaction time is 40min.

[0032] At 35°C, 1.253g of nicotinamide was added to 10mL of model oil solution, stirred for 20 minutes, and left to stand for 10 minutes. The concentration of m-cresol in the upper oil phase was measured by GC, and the volume of the upper oil phase was measured. The removal rate of m-cresol was 90.01%. The upper oil phase was removed, and 20 mL of stripping agent diethyl ether was added to the lower eutectic phase, stirred for 30 min, allowed to stand for 10 min, and subjected to suction filtration, and the solid obtained by vacuum filtration was dried at 60°C for 1 h in a vacuum drying oven, and the recovery was calculated by weighing. The above process was repeated twice, the removal rate of m-cres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com