Method for preparing aliphatic high efficiency water reducing agent by using industrial by-product and application thereof

A high-efficiency water reducer and by-product technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effect of reducing raw material costs, environmental protection and sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

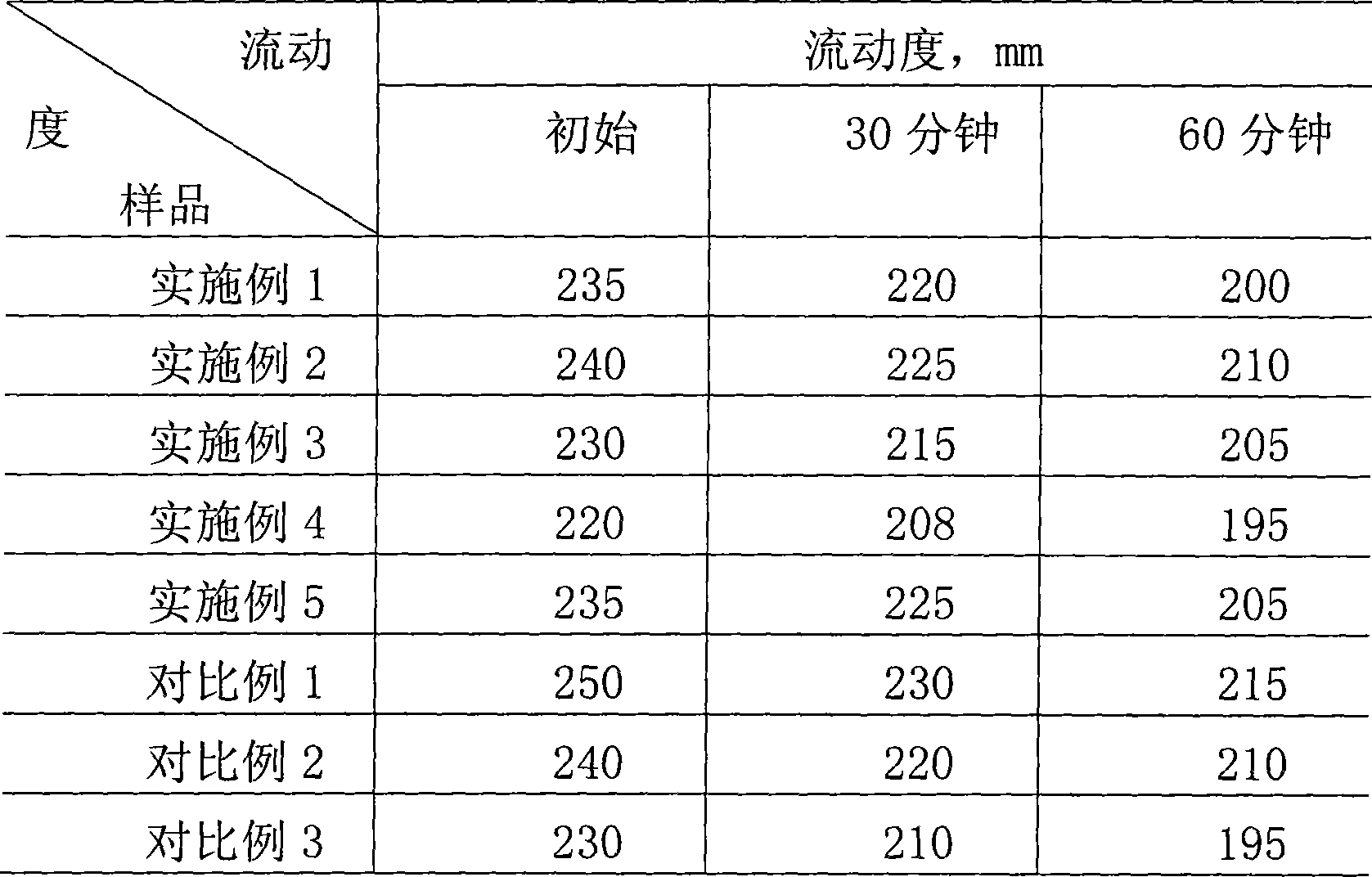

Examples

Embodiment 1

[0015] The synthetic reactions respectively described in this embodiment and the following embodiments are carried out in a reaction vessel equipped with an electric stirrer, a thermometer, a dropping funnel and a reflux condenser.

[0016] First, put 340 grams of water in the reaction vessel, heat it to 36°C, then add 118 grams of p-cresol industrial by-product (sodium sulfite content 60%), stir to dissolve and heat up to 55°C for 30 minutes of hydrolysis reaction; subsequently, add 58 grams of acetone, heated to 63 degrees reflux for 60 minutes; then lower the temperature to 40 degrees Celsius, and dropwise add 243 grams of formaldehyde solution with a concentration of 37% to the above solution; after adding formaldehyde, the temperature of the reaction system will automatically rise As high as 85°C, then heated to 95°C, and reacted at this temperature for 4 hours to obtain a brown-red homogeneous liquid with a solid content of about 34.2%.

Embodiment 2

[0018] First, put 426.3 grams of water into the reaction vessel and heat to 30°C, add 178.2 grams of by-products (sodium sulfite content 65%) of the sulfonated phenol production process, and heat to 45°C for hydrolysis for 30 minutes; then add 88 grams of acetone, Reflux reaction at 62°C for 30 minutes; cool down to 55°C and then add 307.5 grams of 36.5% formaldehyde dropwise to the above solution to carry out carbonylation reaction; after adding formaldehyde, the temperature of the reaction system will automatically rise to 90°C; heat up again to 105°C, and reacted at this temperature for 2 hours to obtain a brownish-red liquid with a concentration of about 37%.

Embodiment 3

[0020] Put into the water of 440 grams in the reaction vessel, be heated to 35 ℃, add 118 grams of p-cresol industrial by-products (sodium sulfite content 60%) again, stir and dissolve and carry out hydrolysis reaction 40 minutes; Subsequently, add 58 grams of acetone, be heated to Reflux reaction at 63°C for 60 minutes; then lower the temperature to 50°C and add 343 grams of formaldehyde with a concentration of 37% to the above solution for carbonylation reaction. After adding formaldehyde, the temperature of the reaction system will automatically rise to 88°C and reheat The temperature was raised to 98° C. for 6 hours to obtain a brown-red homogeneous liquid with a solid content of about 37.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com