Adhesive for wrapping paper material

An adhesive and wrapping paper technology, applied in the direction of adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problems of low strength and poor durability of adhesives, and achieve good mechanical strength. , excellent bonding performance, good bonding performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

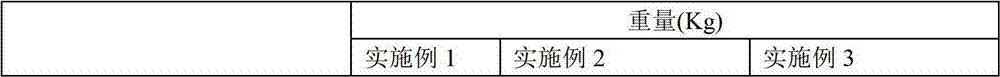

[0024] The components were prepared in the weight ratios shown in Table 1.

[0025] The weight proportion of table 1 embodiment 1~embodiment 3

[0026]

[0027]

[0028] Among the above examples, the cellulose adopts carboxymethyl cellulose; the pigment and filler adopts bentonite; the pH regulator adopts potassium hydroxide; the epoxy resin adopts bisphenol F epoxy resin; the molecular weight of polylactic acid is 100000~200000; Sodium lauryl sulfate is used; polyvinyl alcohol is used for polyol; corn starch is used for plant starch; silane coupling agent KH-570 is used for coupling agent.

[0029] Its preparation method is:

[0030] S1: Grinding the plant starch into a particle size of 20-200 mesh, and grinding the alum into a particle size of 20-200 mesh;

[0031] S2: Dissolve polyol in water, add ethylene-vinyl acetate copolymer, aluminum tripolyphosphate, cellulose, methyl polyolefin resin, polylactic acid, epoxy resin, isooctyl acrylate, acrylamide, 2,6-bis tert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com