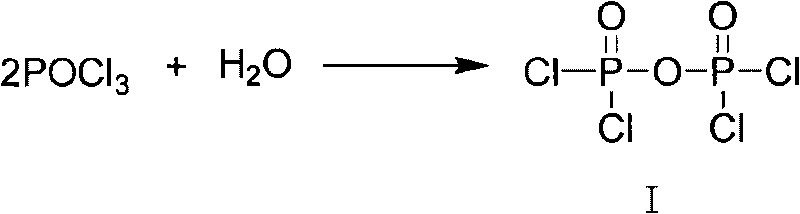

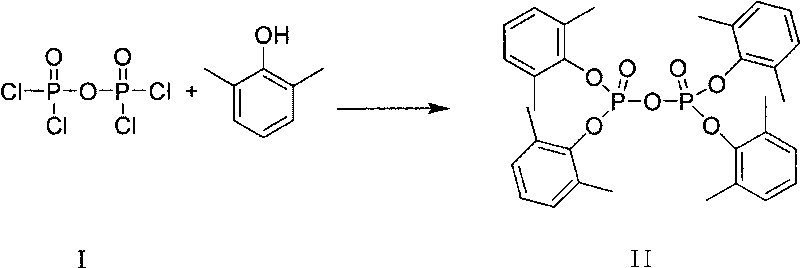

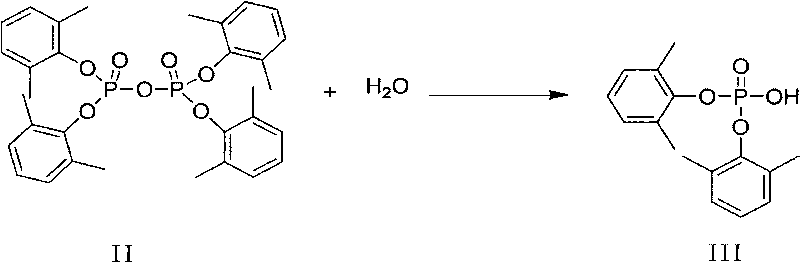

Method for preparing retardant resorcinol bis(2,6-dimethyl ployphosphate ester)

A technology of dimethyl aryl phosphate and resorcinol, which is applied in the field of preparation of sterically hindered aryl bisphosphate, and achieves the effects of less by-products, reduced energy consumption, and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 93.6 g (0.612 mol) of phosphorus oxychloride, 2.8 g of anhydrous zinc chloride, and 0.1 g of phosphorus pentachloride into a four-neck flask equipped with a stirrer, a thermometer, a condenser, an insulating dropping funnel, and a hydrogen chloride absorption device. g, xylene 18.6g, start the agitator, turn on the cooling water of the condenser, and heat to the temperature of the kettle to be 110~117°C, continuously drop 146.4g (1.2mol) of 2,6-xylenol, in 1~ After the dropwise addition is completed within 2 hours, raise the temperature to 145-150°C and react for 3-4 hours to obtain a colorless intermediate product, and the hydrogen chloride produced is recovered by a hydrochloric acid absorption device;

[0027] Next, the temperature of the intermediate was lowered to about 140°C, and 2.8 g of catalyst anhydrous aluminum chloride was added to the intermediate product, stirred evenly, and 32.4 g of resorcinol was continuously added dropwise for 1 hour. Raise it to a...

Embodiment 2

[0029] Add 93.0 g of phosphorus oxychloride, 2.8 g of anhydrous zinc chloride, 0.1 g of phosphorus pentachloride, and xylene 30g, start the agitator, turn on the cooling water of the condenser, and heat the kettle to a temperature of 110-117°C, add 146.4g (1.2mol) of 2,6-dimethylphenol dropwise continuously, dropwise within 1-2 hours After the end, raise the temperature to 145-150°C and react for 3-4 hours to obtain a colorless intermediate product, and the produced hydrogen chloride is recovered through a hydrochloric acid absorption device;

[0030]Next, the temperature of the intermediate was lowered to about 140°C, 2.0 g of catalyst anhydrous aluminum chloride was added to the intermediate product, stirred evenly, and 32.0 g of resorcinol was continuously added dropwise for 3 hours. Raise it to about 150° C., react for 4 hours, monitor the content of the crude product by liquid chromatography, the 2,6-dimethylphenol content in the crude product is 0.04%, and stop the react...

Embodiment 3

[0032] Add 93g of phosphorus oxychloride, 0.3g of anhydrous zinc chloride, 0.05g of phosphorus pentachloride, and 30g of xylene into a four-necked flask equipped with a stirrer, a thermometer, a condenser, an insulating dropping funnel, and a hydrogen chloride absorption device. , start the agitator, turn on the cooling water of the condenser, and heat the kettle until the temperature is 110-117°C, add 146g of 2,6-dimethylphenol continuously dropwise, after the dropwise addition is completed within 1-2 hours, raise the temperature Reaction at 145-150°C for 3-4 hours to obtain a colorless intermediate product, and the hydrogen chloride produced is recovered through a hydrochloric acid absorption device;

[0033] Next, the temperature of the intermediate was lowered to about 140°C, and 2.5 g of catalyst anhydrous aluminum chloride was added to the intermediate product, stirred evenly, and 32 g of resorcinol was continuously added dropwise for 2 hours. After the dropwise addition,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com