Method for preparing aromatic hydrocarbon from methanol or dimethyl ether

A technology of dimethyl ether and methanol, which is applied in the field of producing aromatics from methanol or dimethyl ether, which can solve the problems of severe reaction heat release, low yield of aromatics, catalyst deactivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

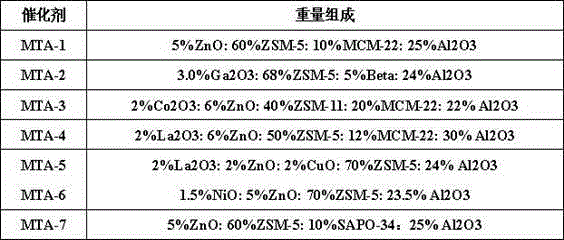

[0020] Weigh 120 grams of ZSM-5 molecular sieve, 20 grams of MCM-22 molecular sieve, 64 grams of pseudoboehmite, 4 grams of scallop powder and mix evenly, add 160 grams of dilute nitric acid solution, knead evenly, and then extrude, dry and roast into a catalyst carrier. The carrier was impregnated with a 15% zinc nitrate solution, dried and calcined to prepare the catalyst MTA-1, whose composition is shown in Table 1.

[0021]

[0022] Table 1

[0023]

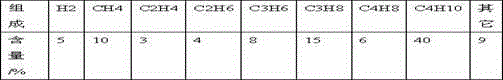

[0024] Take 9 grams of catalyst MTA-1 and put it into a stainless steel fixed-bed reactor. Under the condition of 490°C and normal pressure, feed into the reactor with the weight ratio of methanol:liquefied gas (the composition is shown in Table 2) as 10:1. Make it contact with the catalyst, the reaction space velocity is 2h -1 . The reaction product directly enters the chromatographic on-line analysis through the insulated pipeline. The results are listed in Table 4.

[0025]

[0026] Table 2

[0027]

Embodiment 2-7

[0029] Adopt the method for embodiment 1 to prepare catalyst MTA-2, MTA-3, MTA-4, MTA-5, MTA-6 and MTA-7, its composition is listed in table 1, and adopts the evaluation condition consistent with embodiment 1 to carry out Aromatization reaction, the reaction results are listed in Table 4.

[0030]

Embodiment 8-14

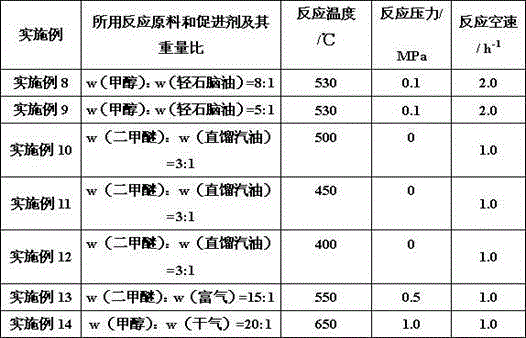

[0035] Take 9 grams of catalyst MTA-5 and put it into a stainless steel fixed-bed reactor. Under different conditions, different raw materials and reaction accelerators are pumped into the reactor to contact with the catalyst. The reaction conditions used, reaction accelerators and their ratios are listed in Table 3. The dry gas used is separated to remove most of the hydrogen. The reaction product directly enters the chromatographic on-line analysis through the insulated pipeline. The results are listed in Table 4.

[0036]

[0037] table 3

[0038]

[0039] Comparing Example 1 and Comparative Example 1 in Table 4, it can be seen that after the introduction of the reaction accelerator and the heat balancer, the yield of the product aromatics has been significantly improved. Comparing Example 3 and Comparative Example 1 yielded the same result. In addition, the introduction of the reaction accelerator and heat balance agent not only balances the exothermic and endothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com