Heavy oil hydrogenation demetalization catalyst as well as preparation method and application of heavy oil hydrogenation demetalization catalyst

A heavy oil hydrogenation and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of lack of large pores in catalysts, low surface acidity of catalysts, etc. problem, to improve the removal performance, reduce the probability of clogging, and reduce the effect of deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

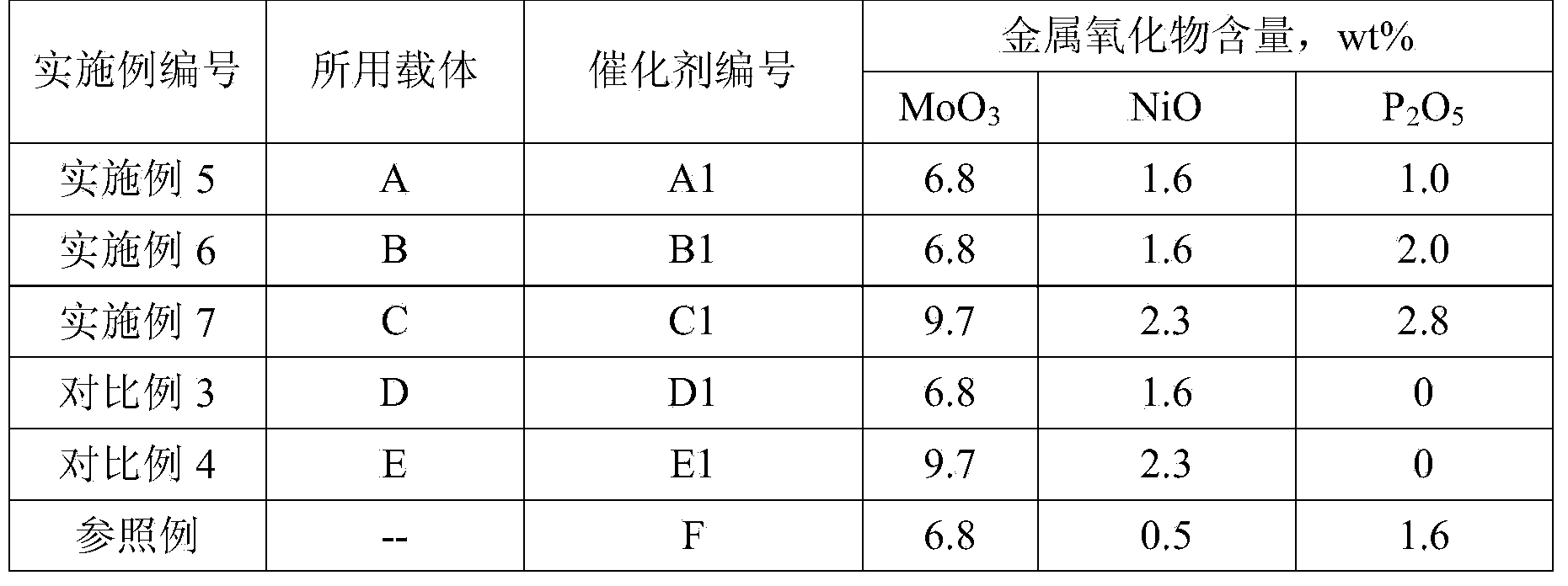

Examples

Embodiment 1

[0037] This embodiment provides a method for preparing an alumina carrier, the specific process is as follows:

[0038] Dissolve 26.51g of ammonium heptamolybdate in 50mL of 30% hot concentrated ammonia water, weigh 50g of activated carbon powder and add it to the solution and mix well to obtain wet activated carbon saturated with adsorbed metal solution;

[0039] Weigh 250g of macroporous alumina dry rubber powder, add 50g of pseudoboehmite and 7.5g of safflower powder; add wet activated carbon to macroporous alumina dry rubber powder, then add 325mL of 12g nitric acid (concentration is 65wt%) Concentrated nitric acid) deionized aqueous solution, make it mix evenly, obtain the alumina dry rubber powder material 1 of mesoporous pre-loaded active metal;

[0040] Then take by weighing 250g of macroporous alumina dry rubber powder, add 50g of pseudoboehmite and 7.5g of safflower powder, add 375mL of deionized aqueous solution containing 170g of ammonium bicarbonate, 4.70g of diam...

Embodiment 2

[0045] This embodiment provides a method for preparing an alumina carrier, the specific process is as follows:

[0046] Dissolve 26.51g of ammonium heptamolybdate in 60mL of 30% hot concentrated ammonia water, weigh 60g of activated carbon powder and add it to the solution and mix well to obtain wet activated carbon saturated with metal solution;

[0047] Weigh 250g of macroporous alumina dry rubber powder, add 50g of pseudoboehmite and 7.5g of safflower powder; add wet activated carbon to macroporous alumina dry rubber powder, then add 315mL of nitric acid containing 12g (concentration is 65wt%) Concentrated nitric acid) deionized aqueous solution, make it mix evenly, obtain the alumina dry rubber powder material 1 of mesoporous pre-loaded active metal;

[0048] Then weigh 250g of macroporous alumina dry rubber powder, add 50g of pseudoboehmite and 7.5g of scallop powder, add 375mL of deionized aqueous solution containing 180g of urea and 21.39g of ammonium dihydrogen phospha...

Embodiment 3

[0053] This embodiment provides a method for preparing an alumina carrier, the specific process is as follows:

[0054] Dissolve 38.81g of ammonium heptamolybdate in 60mL of 30% hot concentrated ammonia water, weigh 60g of activated carbon powder and add it to the solution and mix well to obtain wet activated carbon saturated with metal solution;

[0055] Weigh 300g of macroporous alumina dry rubber powder, add 7.5g of starch; add wet activated carbon to macroporous alumina dry rubber powder, and then add 315mL deionized aqueous solution containing 8g of nitric acid (concentrated nitric acid with a concentration of 65wt%), Make it mix evenly, obtain the alumina dry rubber powder material 1 of mesoporous pre-loaded active metal;

[0056] Then weigh 250g of macroporous alumina dry rubber powder, add pseudoboehmite 50g, safflower powder 7.5g, add 375mL deionized aqueous solution containing ammonium oxalate 190g, ammonium dihydrogen phosphate 15.56g and phosphoric acid 13.60g, mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com