Preparation method and application of hierarchical-pore HZSM-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in molecular sieve catalysts, chemical instruments and methods, and the production of hydrocarbons from oxygen-containing organic compounds, etc., can solve the problems of reduced yield of aromatics, coking of catalyst active centers, and difficulty in entering macromolecular substances. Achieve the effects of increased aromatics yield, reduced coke yield, and less defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Catalyst preparation:

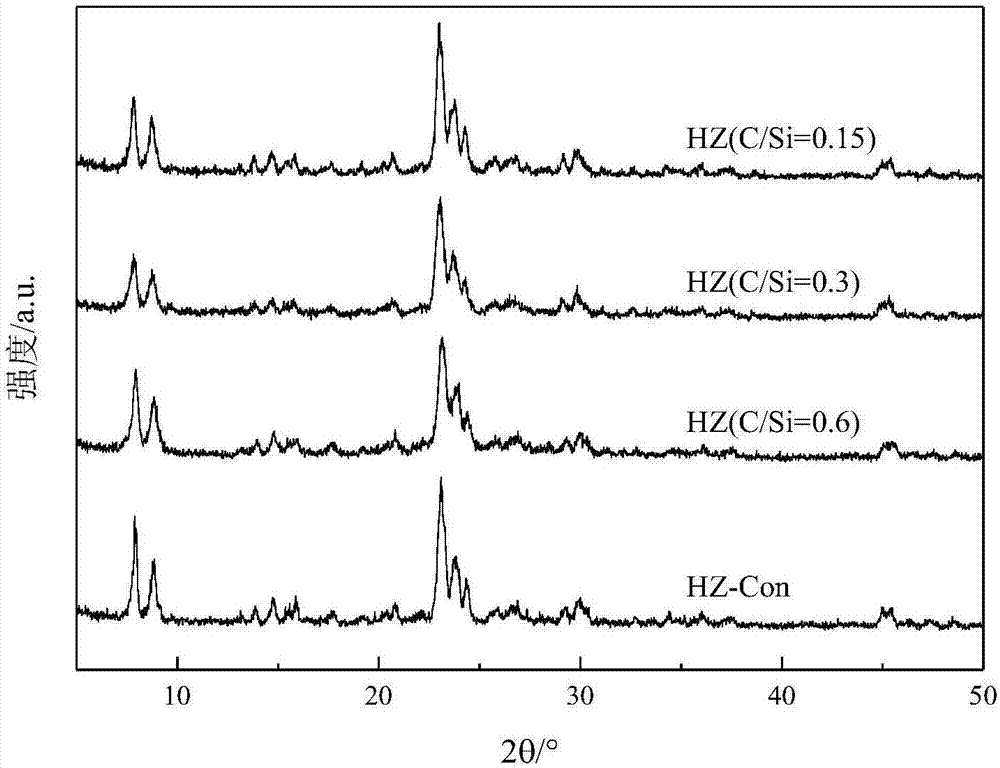

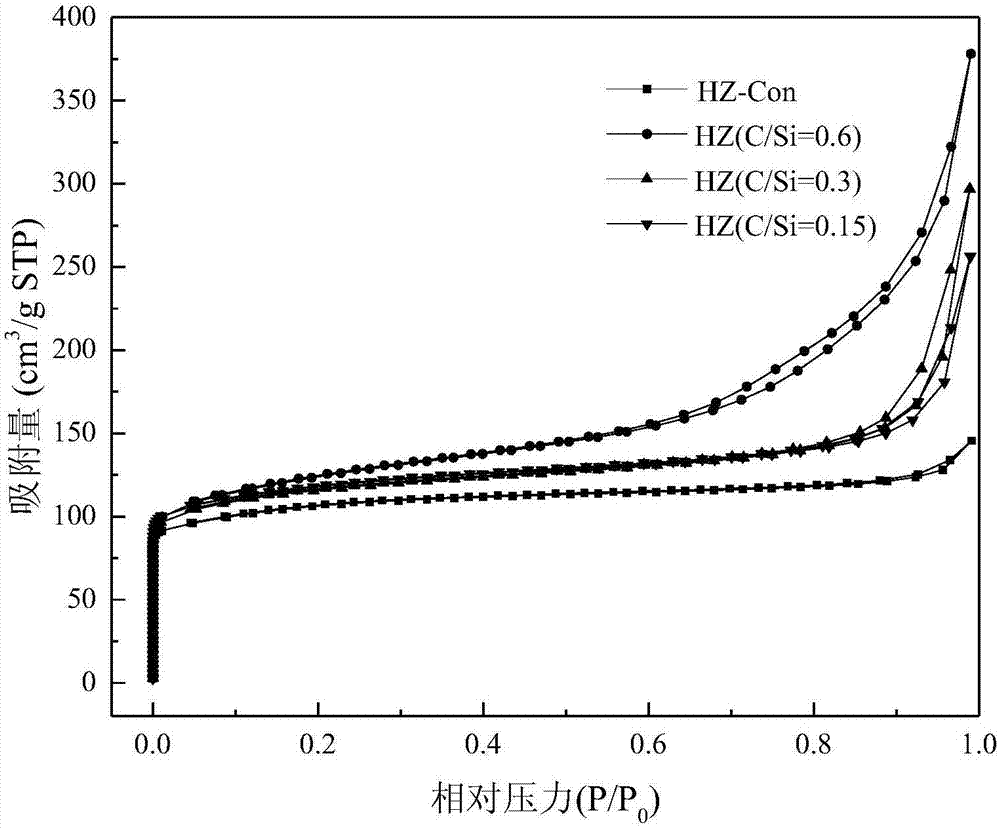

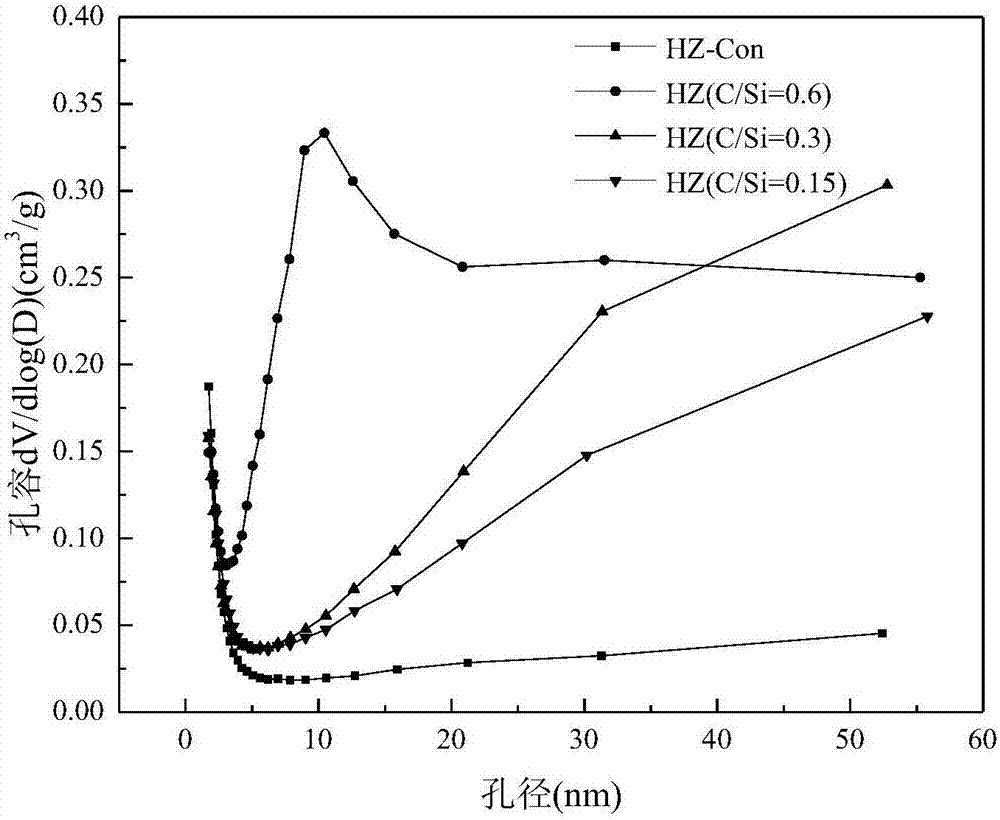

[0044] Dissolve 0.18g of sodium metaaluminate and 4.88g of tetrapropylammonium hydroxide (25% aqueous solution) in 13.5g of water, then dropwise add 6.25g of tetraethyl orthosilicate, mix and prepare a molecular sieve precursor at room temperature, and stir 3h, then pre-crystallized at 90°C under stirring and reflux for 24h, then added 0.13g sucrose, continued to stir for 4h, and then transferred the resulting mixture into a stainless steel reactor with a polytetrafluoroethylene lining , sealed, and hydrothermally crystallized at 170°C for 3 days. After the crystallization, the reaction mixture was separated from solid and liquid, washed thoroughly with deionized water, and the separated solid was dried at 110°C for 12h, and finally placed in a muffle furnace at 550°C Medium calcination for 6 hours to obtain a hierarchically porous ZSM-5 molecular sieve.

[0045]According to the proportion of 1g molecular sieve sample: 50ml of 1mol / l ammonium...

Embodiment 2

[0049] Referring to Example 1, only the amount of sucrose added was changed to 0.26 g, and other conditions remained unchanged, to obtain a hierarchically porous HZSM-5 molecular sieve, which was denoted as HZ (C / Si=0.3).

[0050] The yield of aromatics and coke of the hierarchically porous HZSM-5 molecular sieve prepared in this example catalyzed pyrolysis of cellulose was 38.9% and 27.2%.

Embodiment 3

[0052] With reference to Example 1, only the amount of sodium metaaluminate was changed to 0.12g, and other conditions were unchanged, to obtain a hierarchically porous HZSM-5 molecular sieve, which was denoted as HZ(SiO 2 / Al 2 o 3 =20).

[0053] The yield of aromatics and coke of the hierarchically porous HZSM-5 molecular sieve prepared in this example catalyzed pyrolysis of cellulose was 34.8% and 30.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com