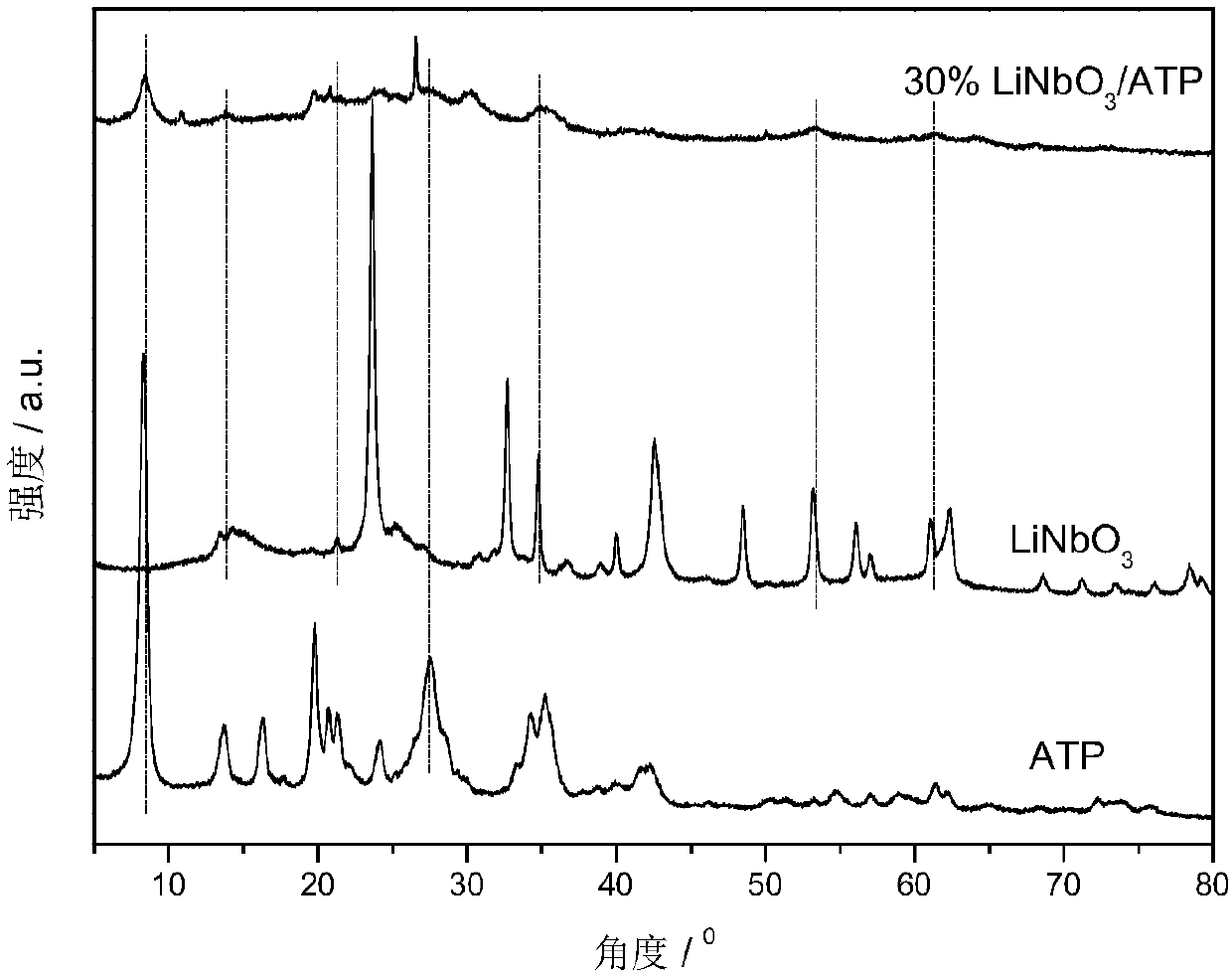

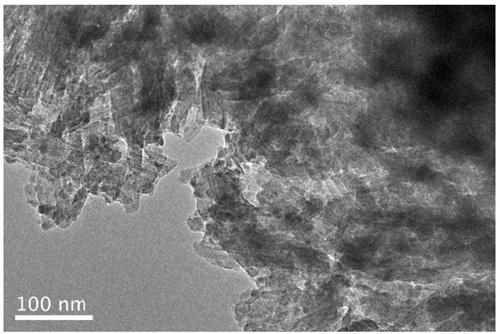

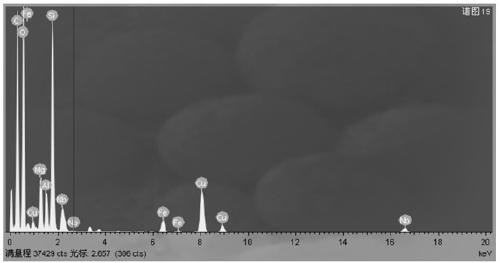

Lithium niobate type oxide/attapulgite non-linear optical composite photocatalytic material as well as preparation method and application thereof

A nonlinear optics and composite photocatalytic technology, which is applied in the field of lithium niobate oxide/attapulgite nonlinear optical composite photocatalytic material and its preparation, can solve the problems of low utilization rate of sunlight and the like, and achieve enlarged light response. The effect of increasing the range, increasing the contact surface, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) 0.3g (0.676mmol) of niobium hydroxide (H 5 Nb 3 o 10 ) into 50ml of 0.2mol / L oxalic acid solution, stirred by the rotor, heated in a water bath at 80°C for 25min to form a transparent solution;

[0028] (2) Drop ammonia solution into the transparent solution formed in step (1), until the white precipitate is completely separated out; wherein the amount of ammonia water is slightly excessive;

[0029] (3) Take the suspension in the middle and lower layers of step (2), centrifuge the precipitate, wash with distilled water, and centrifuge twice, each time at 8000r / min, 2min;

[0030] (4) Dissolve the precipitate in step (3) in 100mL of 0.04mol / L citric acid solution, and dissolve 0.0851g of lithium hydroxide monohydrate (LiOH·H 2 O), molar ratio [Li + ]:[Nb 5+ ]=1:1; heat the water bath to 80°C, after heating for 2 hours, add 1.0g of ATP into the solution; use the sol-gel method, heat the water bath to 80°C, stir with the rotor to form a precursor solution, and heat...

Embodiment 2

[0039] (1) 0.3g (0.676mmol) of niobium hydroxide (H 5 Nb 3 o 10 ) into 50ml of 0.2mol / L oxalic acid solution, stirred by the rotor, heated in a water bath at 80°C for 25min to form a transparent solution;

[0040] (2) Drop ammonia solution into the transparent solution formed in step (1), until the white precipitate is completely separated out; wherein the amount of ammonia water is slightly excessive;

[0041] (3) Take the suspension in the middle and lower layers of step (2), centrifuge the precipitate, wash with distilled water, and centrifuge twice, each time at 8000r / min, 2min;

[0042] (4) Dissolve the precipitate in step (3) in 100mL of 0.04mol / L citric acid solution, and dissolve 0.0851g of lithium hydroxide monohydrate (LiOH·H 2 O), molar ratio [Li + ]:[Nb 5+ ]=1:1, heat the water bath to 80°C, after 2 hours, add 3.0g of ATP into the solution; sol-gel method, keep the temperature of the water bath constant, stir with the rotor to form a precursor solution, heat f...

Embodiment 3

[0047] (1) 0.3g (0.676mmol) of niobium hydroxide (H 5 Nb 3 o 10 ) into 50ml of 0.2mol / L oxalic acid solution, stirred by the rotor, heated in a water bath at 80°C for 25min to form a transparent solution;

[0048] (2) Drop ammonia solution into the transparent solution formed in step (1), until the white precipitate is completely separated out; wherein the amount of ammonia water is slightly excessive;

[0049] (3) Take the suspension in the middle and lower layers of step (2), centrifuge the precipitate, wash with distilled water, and centrifuge twice, each time at 8000r / min, 2min;

[0050] (4) Dissolve the precipitate in step (3) in 100mL of 0.04mol / L citric acid solution, and dissolve 0.0851g of lithium hydroxide monohydrate (LiOH·H 2 O), molar ratio [Li + ]:[Nb 5+ ]=1:1, heat the water bath to 80°C, after 2 hours, add 1.5g of ATP into the solution; sol-gel method, heat the water bath to 80°C, stir with the rotor to form a precursor solution, heat for 4h to steam Dry;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com