Synthetic method for polyoxymethylene dimethyl ether

A polyoxymethylene dimethyl ether and synthetic method technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high production cost and high price, and achieve low production cost, low cost and high adsorption potential high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

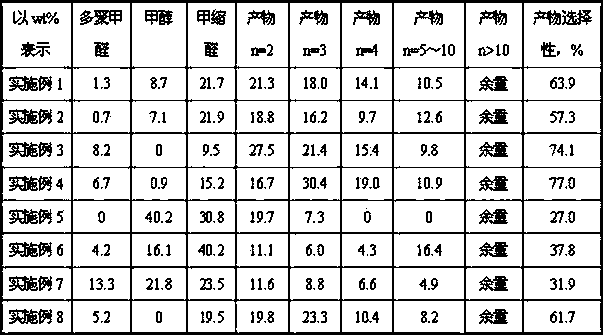

[0015] Add 2 grams of catalyst active C (activated carbon BET specific surface area 2000m 2 / g, pore volume 0.3ml / g), 100 grams of methanol and 100 grams of paraformaldehyde, reacted at 130 ℃ and 0.8MPa autogenous pressure for 4 hours, extracted samples and analyzed them by gas chromatography after centrifugation. The product contains polyoxymethylene dimethyl ether and unreacted raw material methanol and paraformaldehyde, and its composition distribution is shown in Table 1.

Embodiment 2

[0017] Add 2 grams of catalyst active C (activated carbon BET specific surface area 2000m 2 / g, pore volume 0.3ml / g), 100 grams of methanol and 100 grams of paraformaldehyde, reacted at 130 ℃ and 0.6 MPa autogenous pressure for 4 hours, extracted samples and analyzed them by gas chromatography after centrifugation. The product contains polyoxymethylene dimethyl ether and unreacted raw material methanol and paraformaldehyde, and its composition distribution is shown in Table 1.

Embodiment 3

[0019] Add 2 grams of catalyst active C (activated carbon BET specific surface area 2500m 2 / g, pore volume 0.3ml / g), 100 grams of methylal and 100 grams of paraformaldehyde, reacted for 4 hours at 130 ℃ and 0.6 MPa autogenous pressure, the sample was extracted and analyzed by gas chromatography after centrifugation. The product contains polyoxymethylene dimethyl ether and unreacted raw materials methylal and paraformaldehyde, and its composition distribution is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com