Method for preparing polyoxymethylene dimethyl ether carboxylate and methyl methoxy acetate

A technology of polyoxymethylene dimethyl ether and carbonyl, which is applied in the direction of chemical instruments and methods, chemical/physical processes, carbon monoxide or formate reaction preparation, etc., and can solve the conversion rate of methylal to methyl methoxyacetate Unsatisfactory selectivity, low methylal concentration, short catalyst life, etc., to achieve high selectivity, long catalyst life, and high conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

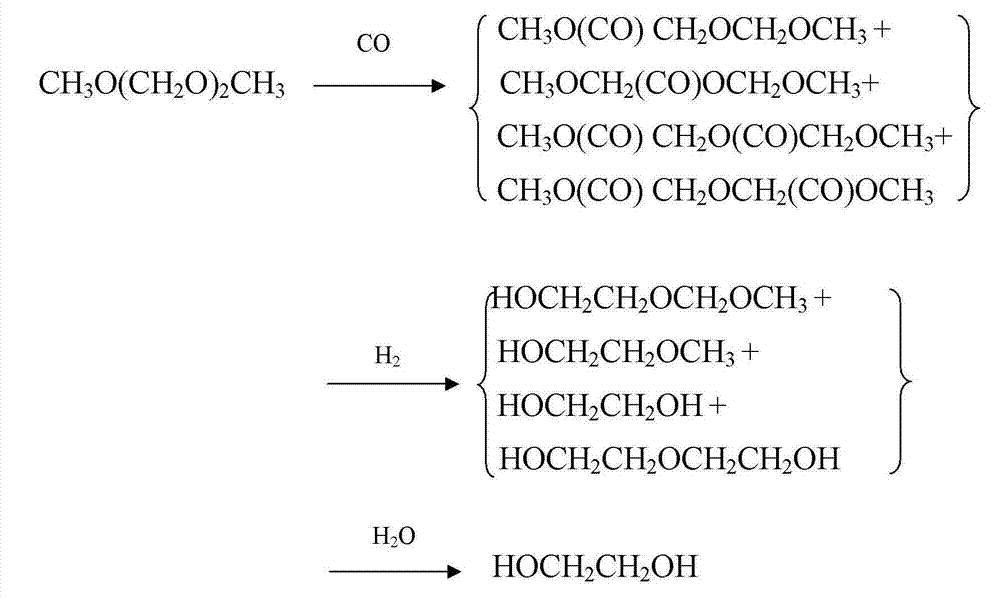

Method used

Image

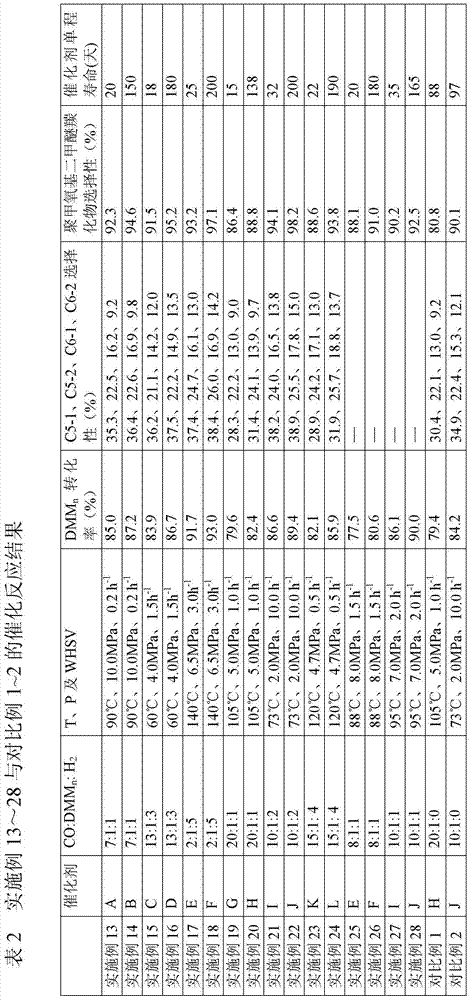

Examples

preparation example Construction

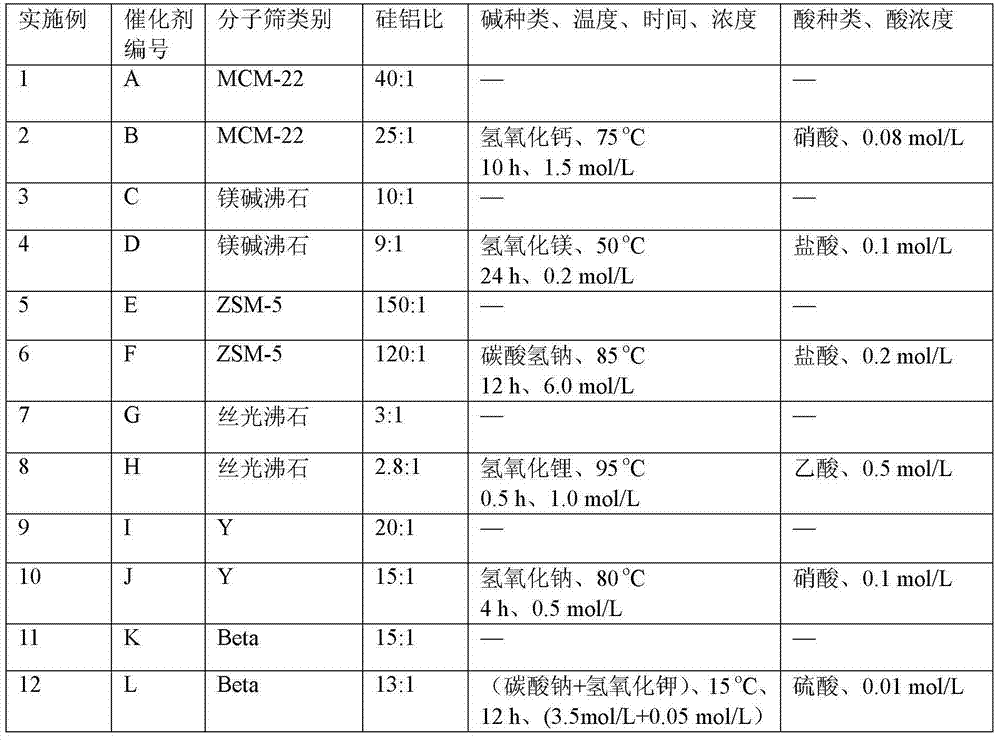

[0037] The preparation method of the acidic molecular sieve catalyst of described desiliconization modification comprises putting molecular sieve into optional 0.05~6.0mol / L, preferably 0.2~1.5mol / L sodium hydroxide, potassium hydroxide, lithium hydroxide, hydroxide In one or several mixed solutions of magnesium, calcium hydroxide, sodium carbonate or sodium bicarbonate, react at 15-95°C, preferably 50-85°C for 0.5-24h, and filter the filter cake with 0.01-0.5mol / Wash with L of hydrochloric acid, nitric acid, sulfuric acid or acetic acid solution to neutralize the acidity of the filter cake, then wash and neutralize the salt solution with deionized water, and then undergo the conventional ammonium ion exchange, filtration, drying, and calcination procedures to obtain desiliconization. Acidic molecular sieve catalyst.

[0038] The structural type of the acidic molecular sieve catalyst is MWW, FER, MFI, MOR, FAU or BEA. Preferably, the acidic molecular sieve catalyst is any on...

Embodiment 1

[0051] 50 g of MCM-22 molecular sieves with a sodium-type silicon-aluminum ratio of 40:1 were converted into acidic molecular sieves using standard operating procedures, which were recorded as catalyst A, as shown in Table 1.

Embodiment 2

[0053] Add 100g of MCM-22 molecular sieve with a sodium-type silicon-aluminum ratio of 40:1 to 500ml of calcium hydroxide solution with a concentration of 1.5mol / L, stir and react at 75°C for 10h, and filter the cake with 0.08ml / L The nitric acid solution was washed until the pH was 6, filtered and washed repeatedly with deionized water until neutral, dried at 100°C and converted into an acidic molecular sieve through standard operating procedures, which was recorded as catalyst B, see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com