Preparation method for paraffin microballoon

A technology of paraffin wax and microspheres, which is applied in the fields of wax physical treatment, medical science, prosthesis, etc., and can solve the problems of the size and shape of paraffin microspheres, the deformation of paraffin microspheres, and the difficulty of sieving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

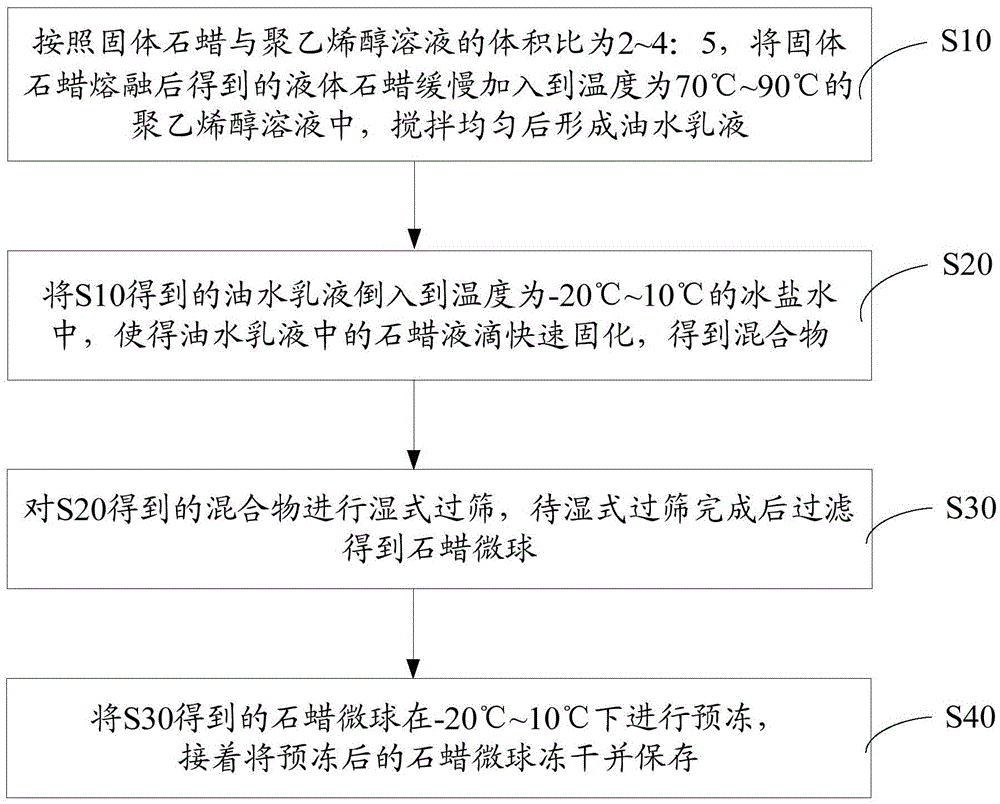

[0027] like figure 1 The preparation method of the paraffin microspheres shown comprises the following steps:

[0028] S10. According to the volume ratio of the solid paraffin to the polyvinyl alcohol solution being 2 to 4:5, the liquid paraffin obtained by melting the solid paraffin is slowly added to the polyvinyl alcohol solution at a temperature of 70° C. to 90° C. After stirring, it forms Oil-to-water emulsion.

[0029] The mass percentage content of the solute in the polyvinyl alcohol solution is 0.5% to 5%.

[0030] The temperature of the liquid paraffin obtained after the solid paraffin is melted is 50°C to 200°C.

[0031] S20. Pour the oil-water emulsion obtained in S10 into ice brine at a temperature of -20°C to 10°C, so that the paraffin droplets in the oil-water emulsion are rapidly solidified to obtain a mixture.

[0032] The solute of the ice brine is selected from at least one of sodium chloride, potassium chloride, magnesium chloride and calcium chloride.

...

Embodiment 1

[0050] Put 160 mL of solid paraffin into a beaker and heat it to melt to obtain liquid paraffin with a temperature of 50°C.

[0051] 200 mL of 0.5% polyvinyl alcohol solution was prepared, heated and stirred to 75°C.

[0052] All the above-mentioned liquid paraffin was added to 200 mL of polyvinyl alcohol solution at a slow speed, and an oil-water emulsion was formed after stirring uniformly.

[0053] The above-mentioned oil-water emulsion was poured into ice brine (22.5wt%, NaCl) at a temperature of -20°C, so that the paraffin droplets in the oil-water emulsion were rapidly solidified to form solid paraffin microspheres, thereby obtaining a mixture.

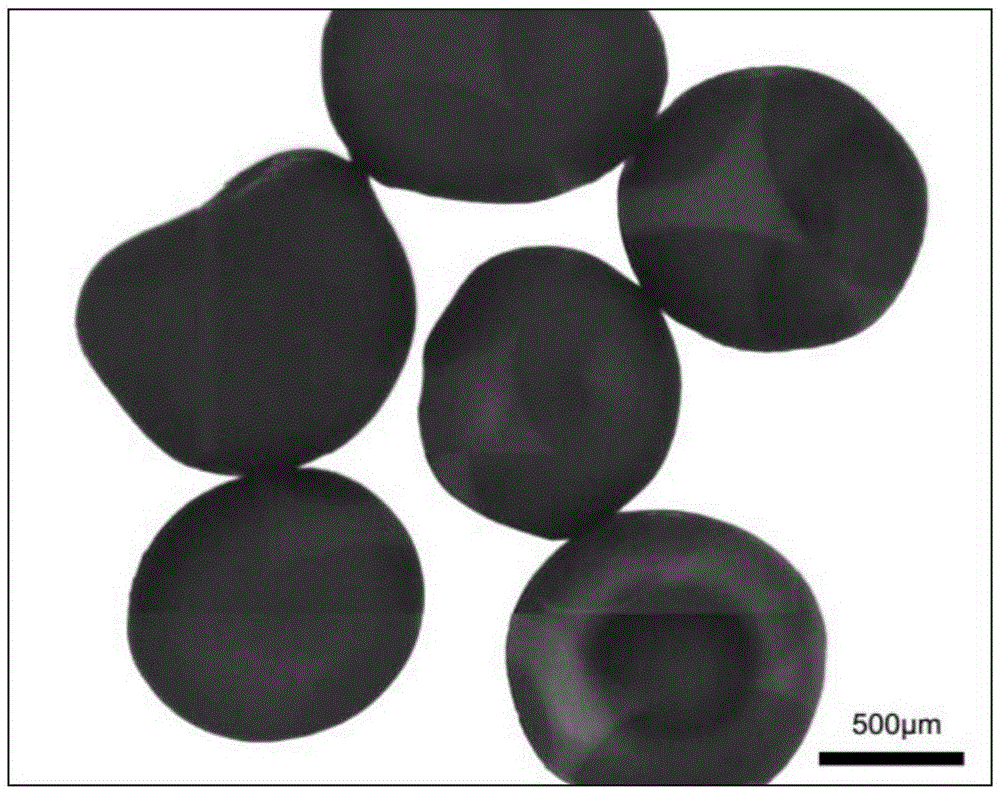

[0054] The mixture was poured into a combination of 10-mesh and 20-mesh standard vibrating sieves for wet sieving, the vibration frequency was 150 rpm, and the purified water was continuously rinsed at 4°C to accelerate the sieving of paraffin microspheres, and simultaneously remove residual dispersant and ice brine.

[0055] T...

Embodiment 2

[0058] Put 80 mL of solid paraffin into a beaker and heat it to melt to obtain liquid paraffin with a temperature of 80°C.

[0059] 200 mL of 2% polyvinyl alcohol solution was prepared, heated and stirred to 86°C.

[0060] All the above-mentioned liquid paraffin was added to 200 mL of polyvinyl alcohol solution at a slow speed, and an oil-water emulsion was formed after stirring uniformly.

[0061] The above-mentioned oil-water emulsion was poured into ice brine (10wt%, NaCl solute) at a temperature of -5°C, so that the paraffin droplets in the oil-water emulsion were rapidly solidified to form solid paraffin microspheres, thereby obtaining a mixture.

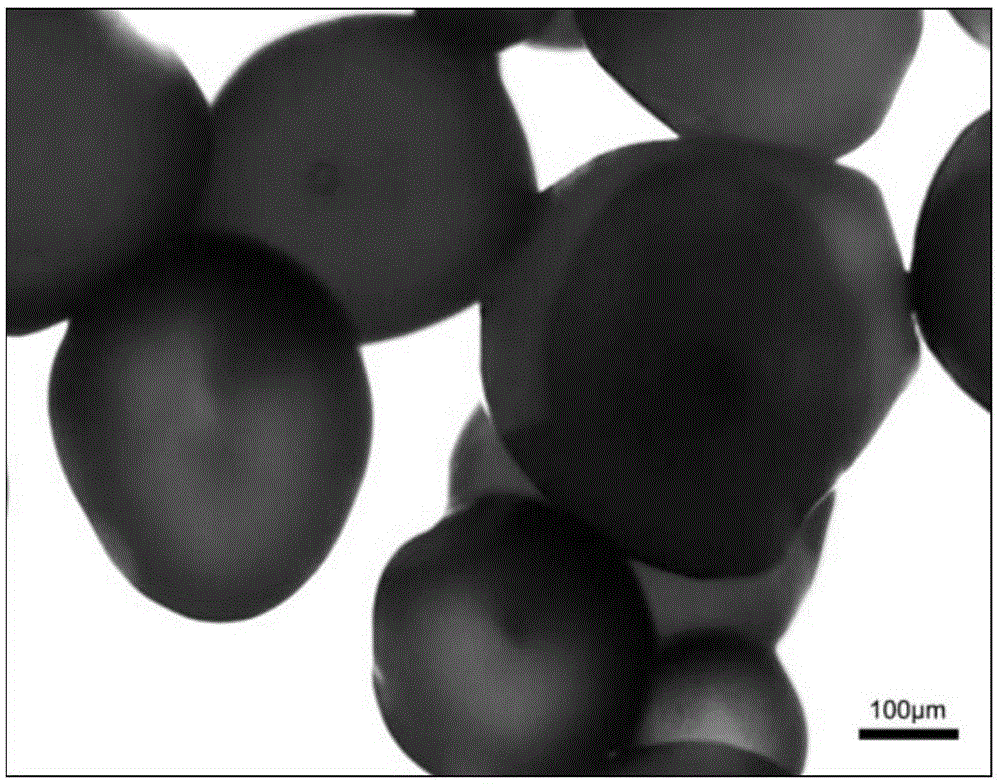

[0062] The mixture was poured into a combination of 20-mesh and 50-mesh standard vibrating sieves for wet sieving, the vibration frequency was 600 rpm, and the purified water was continuously rinsed at 4°C to accelerate the sieving of paraffin microspheres, and simultaneously remove residual dispersant and ice brine.

[0063] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com