Super-high molecular weight polyethylene low frictional coefficient wearable composite material and its preparation and use

A technology of ultra-high molecular weight and composite materials, applied in the field of polymer materials and their preparation, can solve problems such as grinding surface scratches, excessive fiber content, fatigue wear, etc., and achieve fast sliding speed, low friction coefficient and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments.

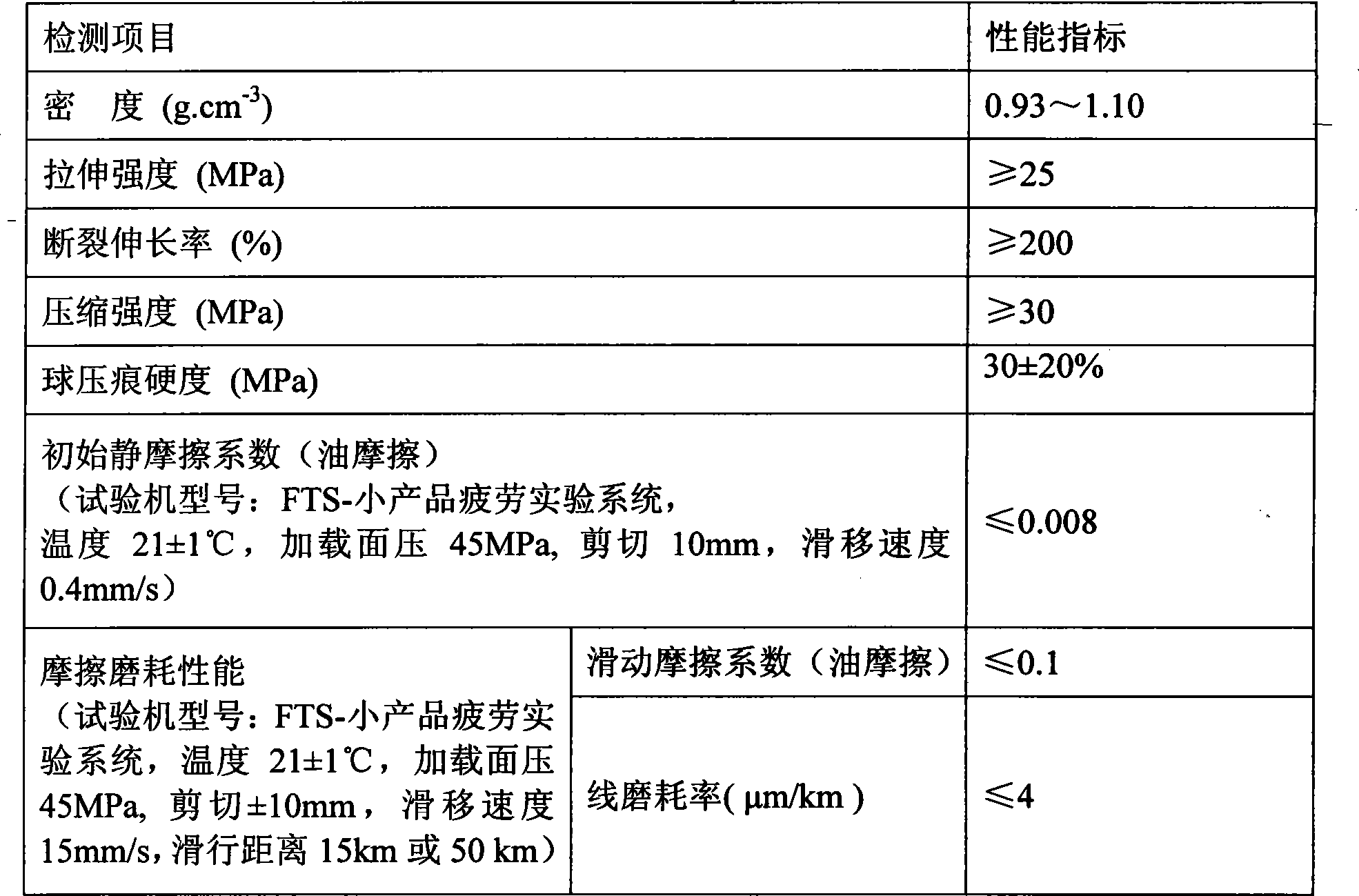

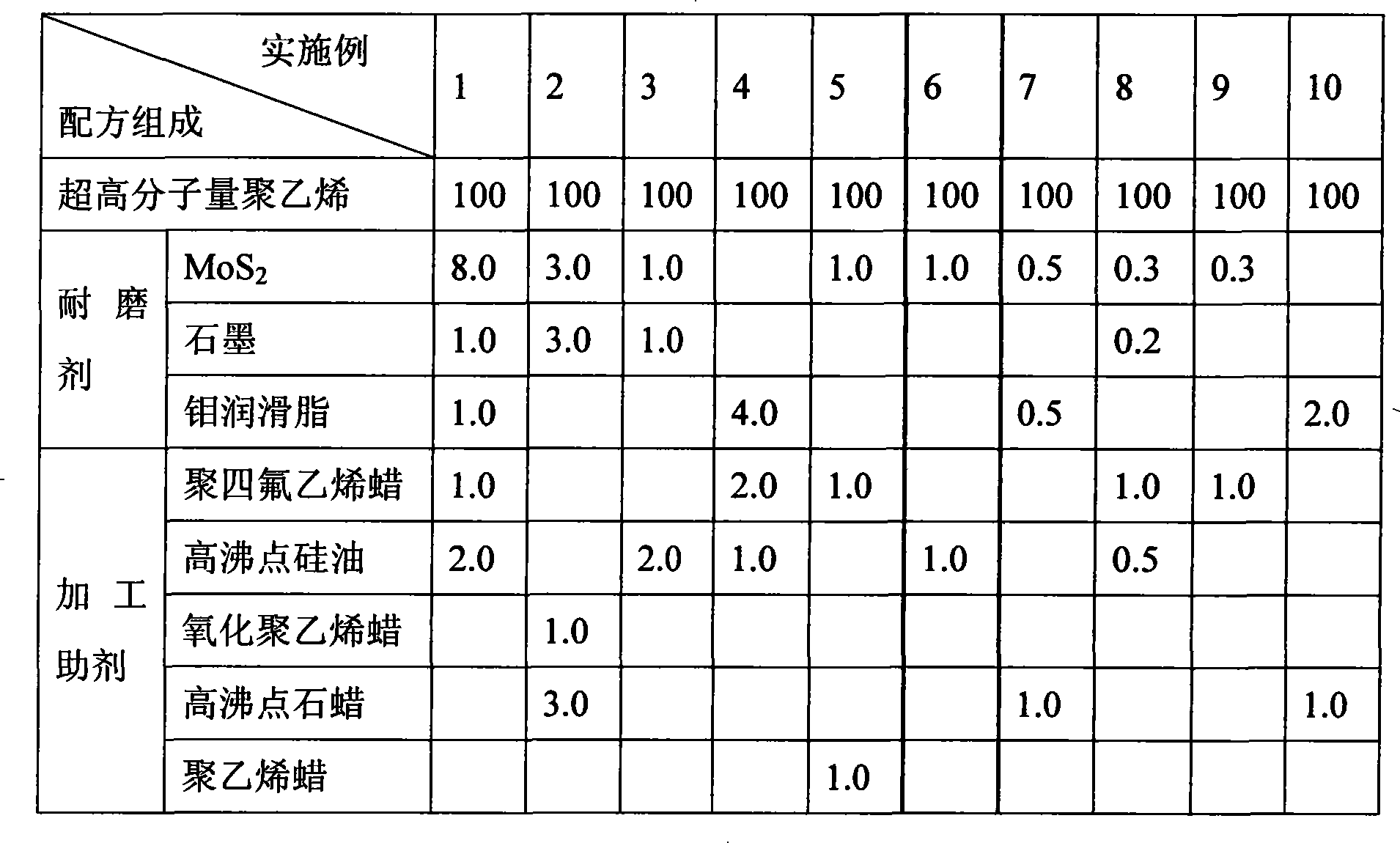

[0019] The formula composition of embodiment 1 to embodiment 10 is as table 2. It can be seen from the table that the present invention is a kind of ultra-high molecular weight polyethylene low-friction high-wear-resistant composite material, and its formula is:

[0020] 100 parts of ultra-high molecular weight polyethylene;

[0021] Wear-resisting agent 0.1~10 parts;

[0022] Processing aid 0.1~5.0 parts;

[0023] The ultra-high molecular weight polyethylene is ultra-high molecular weight polyethylene with a matrix molecular weight ≥ 6 million.

[0024] The wear-resisting agent is MoS treated by coupling agent surface 2 , graphite, molybdenum grease or copper powder, or a mixture of two or more thereof, the MoS 2 , graphite and copper powder are surface treated by coupling agent, the particle size is 3-20μm, and the molybdenum grease is MoS 2 Grease, the coupling age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com