Uniform feeding method and device by adopting wet sieving method

A uniform and feeding technology, applied in chemical instruments and methods, screening, solid separation, etc., can solve the problems of reduced screening efficiency, uneven material distribution, distortion and deformation of feeding chute, etc., to reduce labor intensity of workers and improve The effect on work rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the implementation examples.

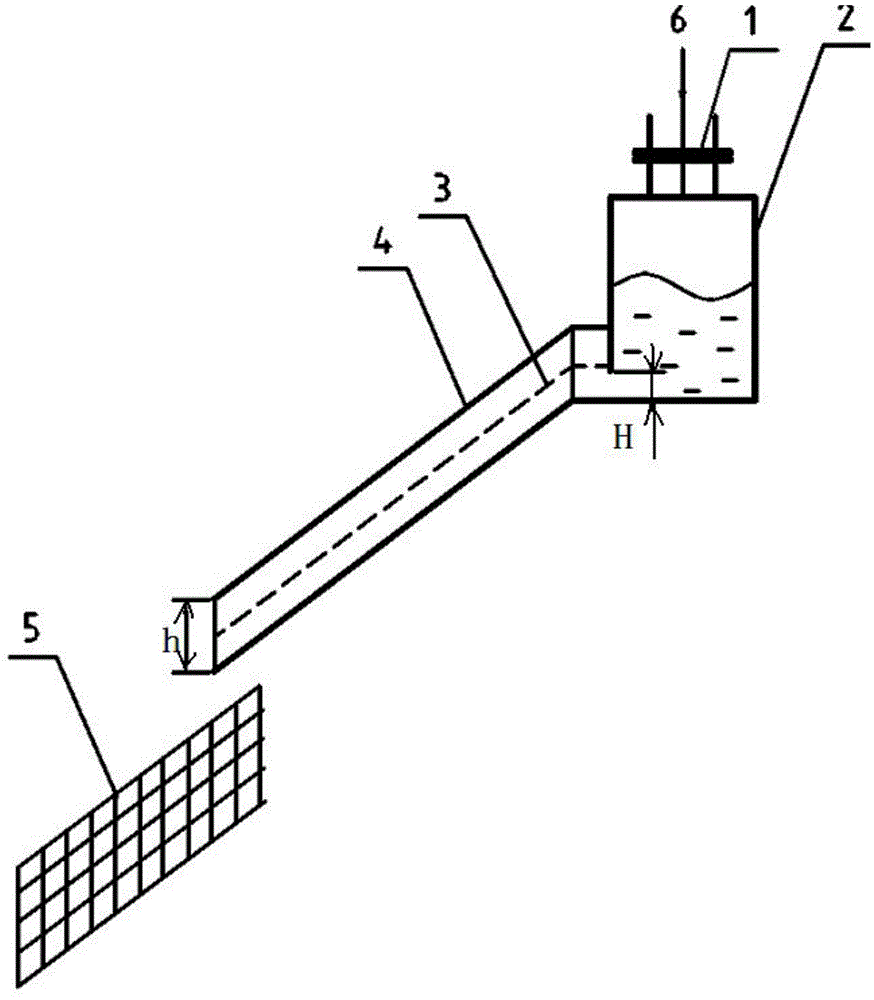

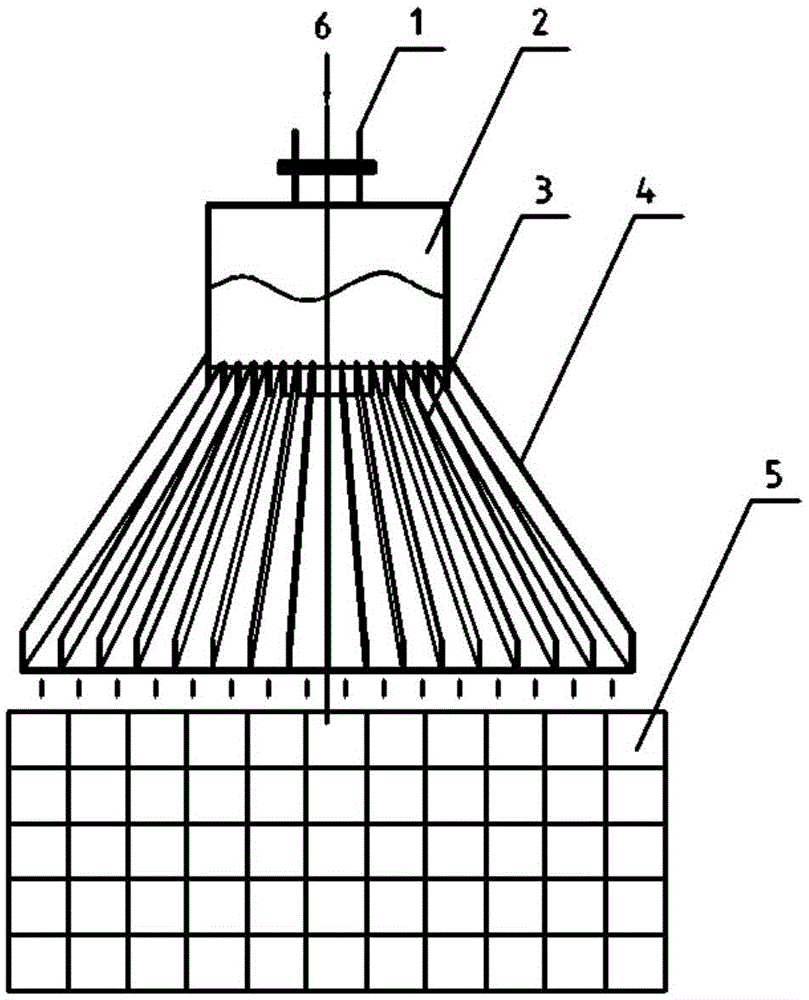

[0022] like figure 1 , figure 2 As shown, the device is divided into two parts, the feed buffer box 2 and the distribution chute. The feed buffer box 2 is a closed structure, with a feed inlet at the top and a rectangular discharge outlet at the bottom. According to the qualified pulp flow rate, the outlet velocity of the pulp is between 0.5 and 1.5m / s, and the height H of the outlet of the feed buffer box is reasonably determined accordingly. If the flow rate is too fast, it is easy to cause spraying, and if it is too slow, it will cause the slurry to settle at the outlet.

[0023] The distribution chute is a fan-shaped structure, and the width of the outlet end is the same as the width of the high-frequency sieve screen 5. There are multiple baffles 3 inside the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com