Fumed silica and production method therefor

A fumed silica, chemical mechanical technology, applied in the direction of silica, silicon oxide, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of fumed silica in this embodiment is not particularly limited, and any preparation method of silica microparticles can be used, as long as the BET specific surface area of the prepared silica microparticles is 57m 2 / g above 400m 2 / g or less, and the residual amount on the sieve obtained by using an electroforming sieve with a mesh size of 5 μm and performing a wet sieving method is less than 5 ppm. Specifically, for example, there is a method of supplying a silane compound to a reactor, burning it in a flame, or hydrolyzing it. For example, you can refer to Japanese Patent Publication No. 47-46274, Japanese Patent Publication No. 58-54085, Japanese Patent Application Publication No. 59-169922, Japanese Patent Application Publication No. 59-184721, and Japanese Patent Application Publication No. 60-011218. The methods described in each gazette.

[0040] Fumed silica is produced by supplying a source gas containing a silane compound to a flam...

Embodiment 1 to Embodiment 3

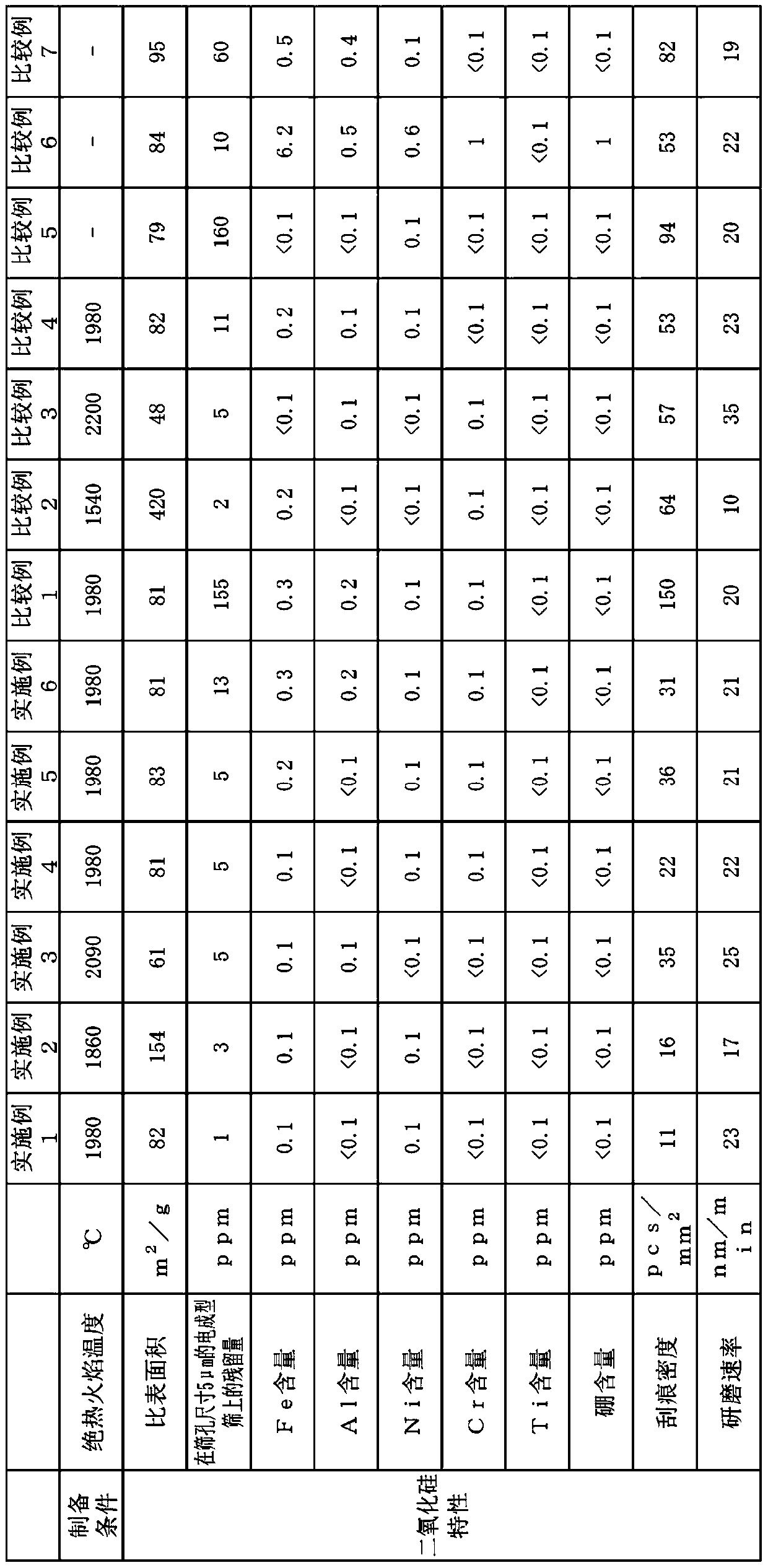

[0100] Tetrachlorosilane was used as the halogenated silane, which was subjected to a flame hydrolysis reaction under the preparation conditions described in Table 1, thereby preparing fumed silica, which was recovered after the separation and recovery process. The amount of impurities in the above-mentioned tetrachlorosilane gas is as follows. Iron: less than 0.1ppm, aluminum: less than 0.1ppm, nickel: less than 0.01ppm, chromium: less than 0.01ppm, titanium: less than 0.01ppm, boron: less than 0.01ppm.

[0101] 250 g of this fumed silica was introduced into a fluidized bed made of quartz glass with an inner diameter of 15 cm. at 5Nm 3 The rate of / h is introduced from the lower part and is heated to the preheated air that temperature is roughly identical with fumed silica, and the introduction time is 30 minutes, after that, take out 225g of silica in the silica that has been introduced from the upper part of the tube, thus Graded. The classified fumed silica is recovered...

Embodiment 4

[0103] The halogenated silane is the same as in Example 1, using tetrachlorosilane, which undergoes a flame hydrolysis reaction under the preparation conditions described in Table 1, thereby preparing fumed silica, which is recovered after the deacidification process. 250 g of this fumed silica was introduced into a fluidized bed made of quartz glass with an inner diameter of 15 cm. at 5Nm 3 The rate of / h is introduced from the lower part and is heated to the preheated air that temperature is roughly identical with fumed silica, and the introduction time is 30 minutes, after that, take out 225g of silica in the silica that has been introduced from the upper part of the tube, thus Graded. This classification step was repeated twice to obtain 203 g of fumed silica. The obtained fumed silica was compressed with a degassing press, whereby the bulk density was adjusted to 0.05 g / cm 3 fumed silica powder. The specific surface area of the obtained fumed silica, the impurity co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com