Method for separating silicon from residuals

A technology of plasma and cooling liquid, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of reducing silicon production efficiency, complex post-cleaning silicon process, unsatisfactory effectiveness and economy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

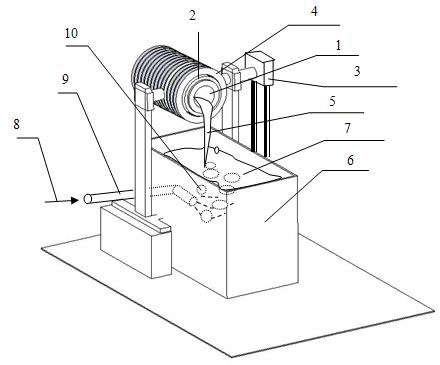

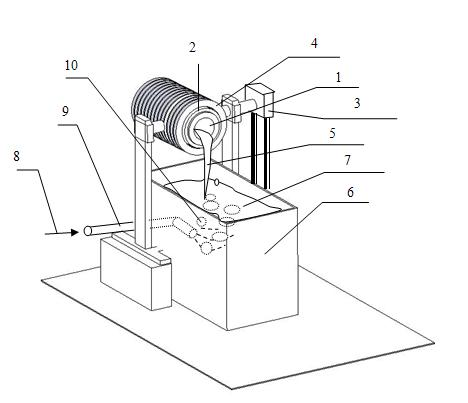

Image

Examples

specific Embodiment approach 2

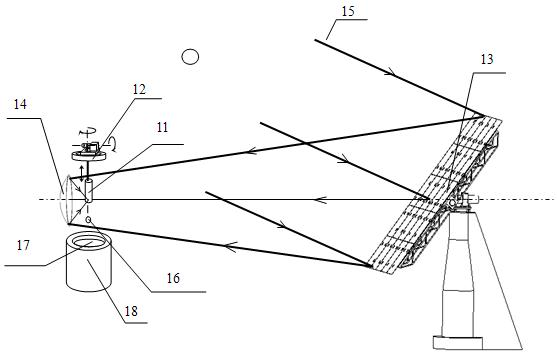

[0017] The schematic diagram of specific embodiment 2 is as figure 2 shown. 500g industrial silicon powder, 250g SiO 2 Powder and 250g CaO powder mixed powder is pressed into a cylindrical silicon rod 11 with a 200T high-pressure oil press and a mold, suspended with a feeder 12, and one end of the silicon rod 11 is placed in the high temperature zone of the solar furnace 13. SiO2 and CaO are a kind of slag agent, and its dosage, composition and ratio can be changed according to the needs of users. As long as silicon and slag can be completely melted, it will not affect the use of the present invention, which is related to the scope of use of the present invention. . The secondary concentrator 14 of the solar furnace 13 gathers the sunlight 15 by 10,000 times and irradiates it on the silicon rod 11. The silicon rod 11 melts rapidly, and the melt of silicon and slag falls down freely due to gravity, and the droplet-shaped silicon and slag Liquid 16 falls into cooling liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com