Wet and dry sieve shaker for laboratory

A dry-wet dual-use, laboratory technology, applied in sieves, solids separation, grids, etc., can solve the problems of low efficiency and high labor intensity, and achieve the frequency adjustment, reduce labor intensity, and improve equipment utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the present invention is not limited.

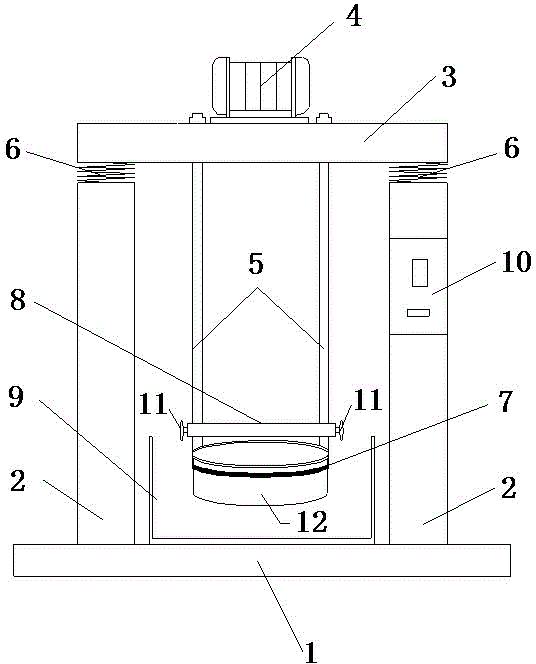

[0011] With reference to accompanying drawing, the present invention comprises base 1, frame 2, vibrating support 3, vibrating motor 4, vibrating connecting rod 5, vibrating spring 6, collar 7, locking slide bar 8, water tank 9 and control panel 10. Wherein, the frame 2 and the base 1 are welded as one, the vibrating support 3 is connected with the frame 2 through the vibrating spring 6, the vibrating motor 4 is fixed on the vibrating support 3, and its vibration frequency can be adjusted steplessly by a frequency converter. One end of the vibrating connecting rod 5 is fixed on the vibrating support 3, and the other end is fixed with a collar 7. The locking sliding rod 8 can slide up and down on the vibrating connecting rod 5, and both ends of the locking sliding rod 8 are provided with rotating screw rods 11. The wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com