Homogeneous crosslinking beta-cyclodextrin/wolfram carbine composite microsphere and method of producing the same

A composite microsphere and cyclodextrin technology, which is applied in the direction of microsphere preparation, chemical instruments and methods, microcapsule preparation, etc., can solve the problems that cannot meet the expansion requirements and have not yet been applied, and achieve low cost, good chemical stability, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

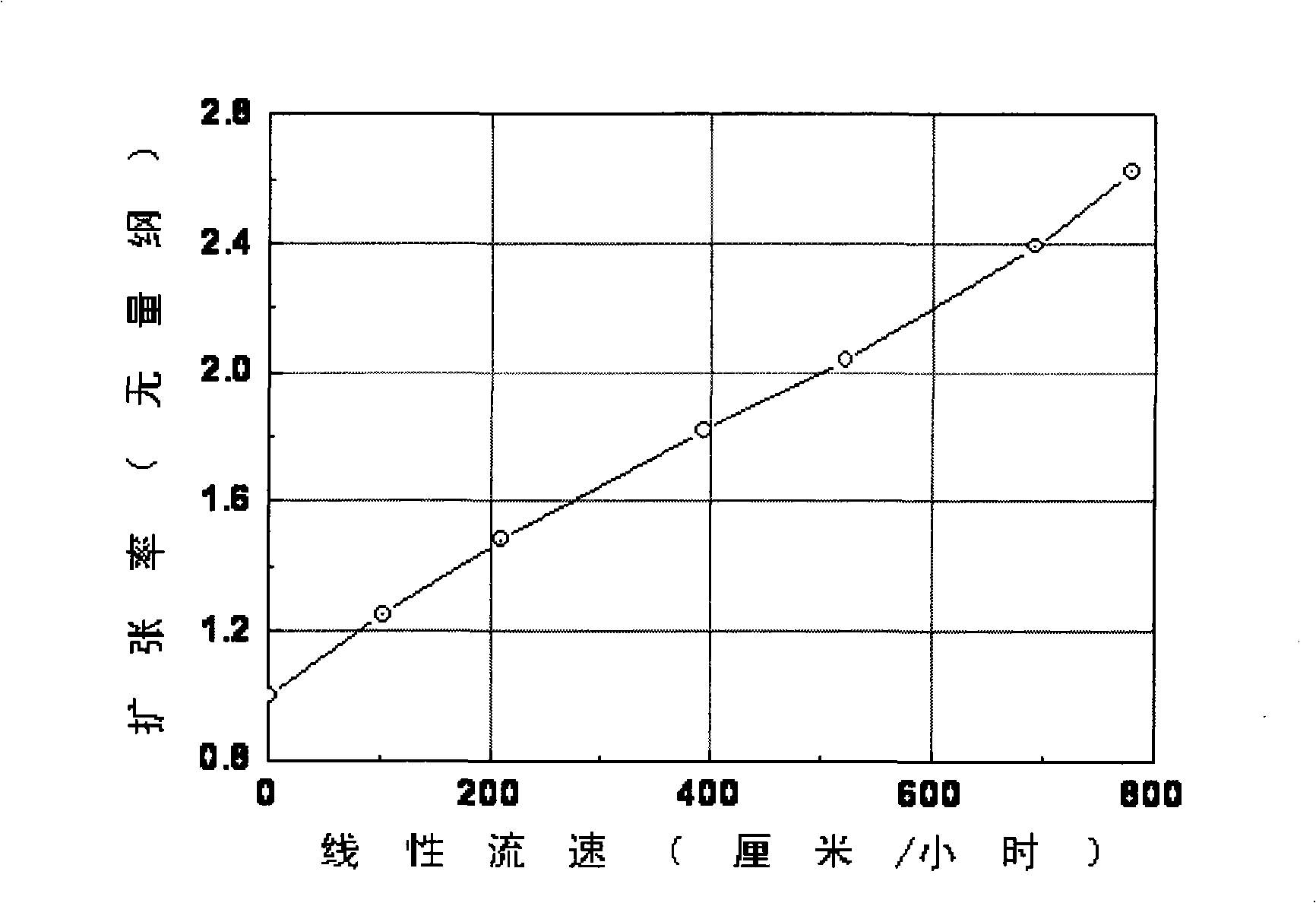

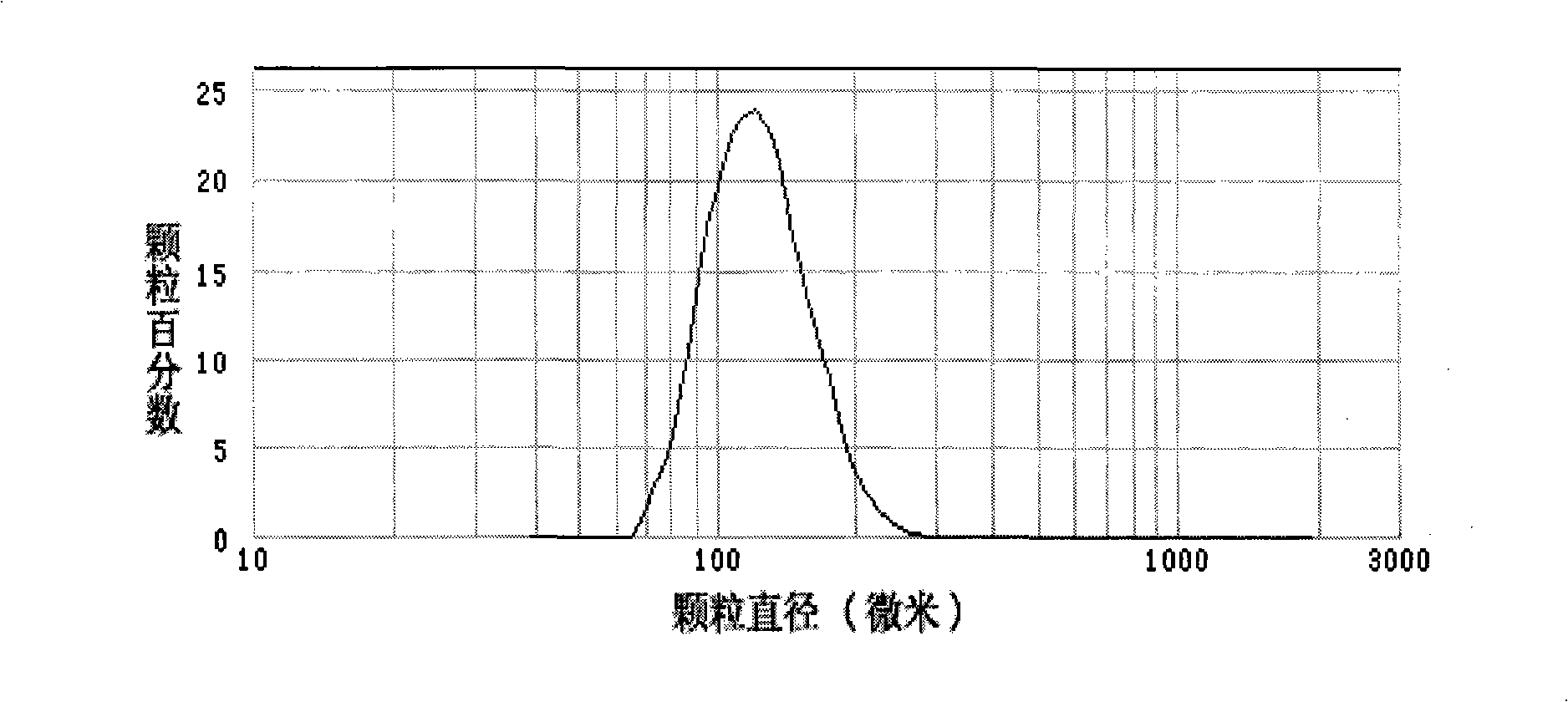

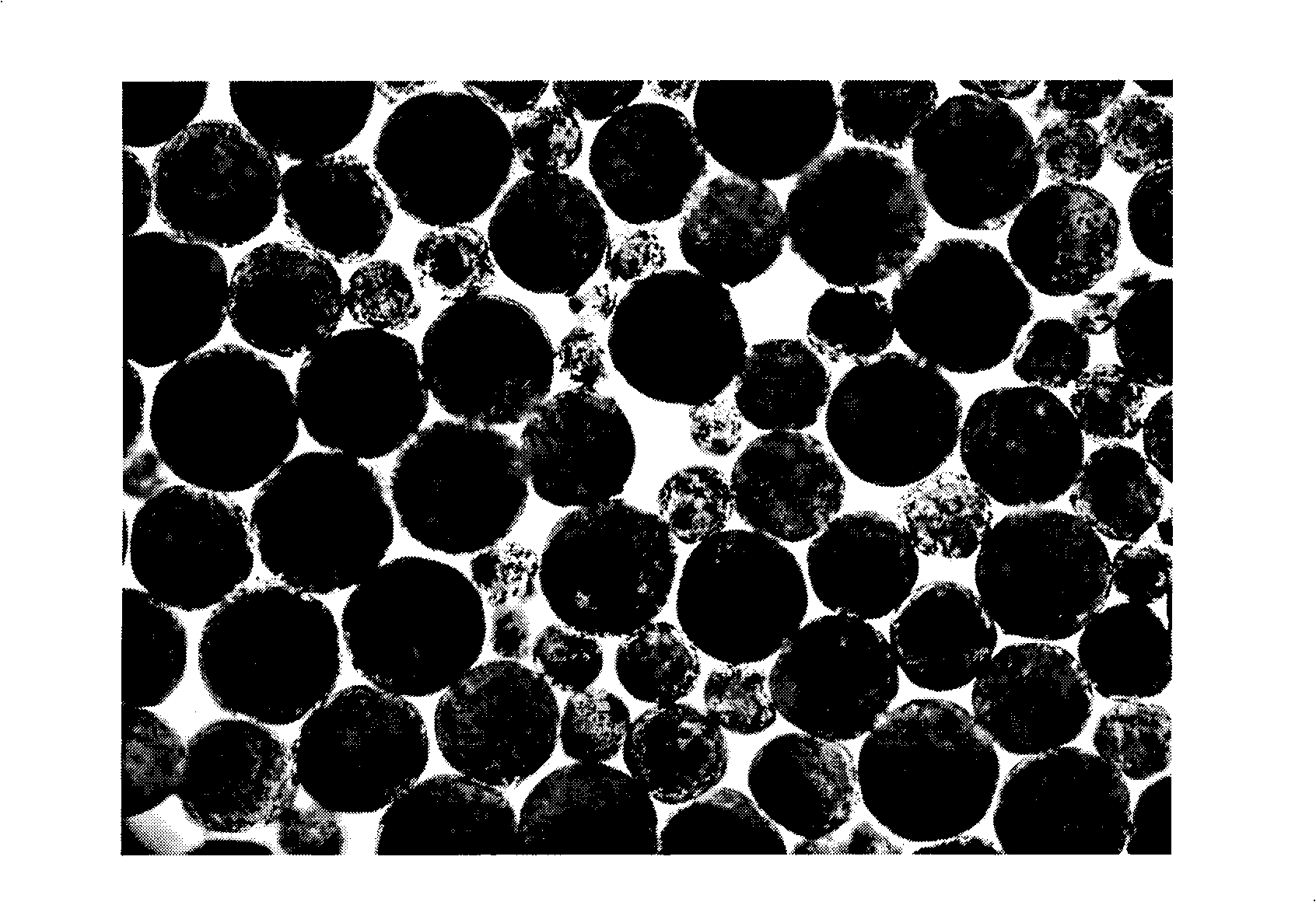

[0029] At 60°C, mix 8g of β-cyclodextrin and 40g of 20% sodium hydroxide aqueous solution to prepare a solution. Under mechanical stirring, add 8g of epichlorohydrin dropwise to the solution for 30 minutes, and then continue stirring for 30 minutes to obtain viscous Glue: add 14g of tungsten carbide powder to the viscose, mix and stir evenly, at 50°C, under the condition of mechanical stirring speed of 300rpm, add 42g of high-speed vacuum pump oil and 126g of liquid paraffin oil dispersion phase, and add 0.84g of polyoxyethylene sorbitan monooleate was used as a dispersant, after stirring for 15min, 2.5g of epichlorohydrin was added, and stirred for 120min at 50°C with a mechanical stirring speed of 300rpm to obtain a black homogeneous Quality-type composite microspheres; cooled to 20°C, then mixed evenly with 0.5 times the volume of n-hexane, filtered under reduced pressure, filtered out the composite microspheres from the oil dispersed phase, and then divided into 2 parts wit...

Embodiment 2

[0031]At 90°C, mix 24g of β-cyclodextrin and 40g of 40% aqueous sodium hydroxide solution to prepare a solution. Under mechanical stirring, add 16g of epichlorohydrin dropwise to the solution for 45min, and then continue stirring for 120min to obtain viscous Glue: Add 120g of tungsten carbide powder to the viscose and mix it evenly. At 70°C and the mechanical stirring speed is 450rpm, add 266g of high-speed vacuum pump oil and 133g of liquid paraffin. 6.0g polyoxyethylene sorbitan monooleate as a dispersant, after stirring for 30min, add 30g of epichlorohydrin, and stir for 180min at 70°C with a mechanical stirring speed of 450rpm to obtain a black homogeneous type composite microspheres; cooled to 30°C, then mixed evenly with 1 times the volume of n-hexane, filtered under reduced pressure, filtered out the composite microspheres from the oil dispersed phase, and then divided into 3 times with 4 times the volume of n-hexane After washing, the composite microspheres were added ...

Embodiment 3

[0033] At 80°C, mix 20g of β-cyclodextrin and 40g of 25% aqueous sodium hydroxide solution to prepare a solution. Under mechanical stirring, add 10g of epichlorohydrin dropwise to the solution for 30min, and then continue stirring for 60min to obtain viscous Glue: add 30g of tungsten carbide powder to the viscose, mix and stir evenly, at 60°C, under the condition of mechanical stirring speed of 400rpm, add 90g of high-speed vacuum pump oil and 200g of liquid paraffin oil dispersion phase, and add 2.5g of polyoxyethylene sorbitan monooleate as a dispersant, after stirring for 30min, add 10g of epichlorohydrin, and stir for 150min at 60°C with a mechanical stirring speed of 400rpm to obtain a black homogeneous Type composite microspheres; suction filtration, washing, neutralization, sieving and flotation according to the method in Example 2, to obtain 72 mL of composite microspheres with a particle size of 75-180 μm and a density of 1.4 g cm -3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com