Vibrating screen for wet sieving

A technology of wet sieving and vibrating sieve, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc. It can solve problems such as easy blockage of meshes, and achieve the effect of improving utilization rate and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

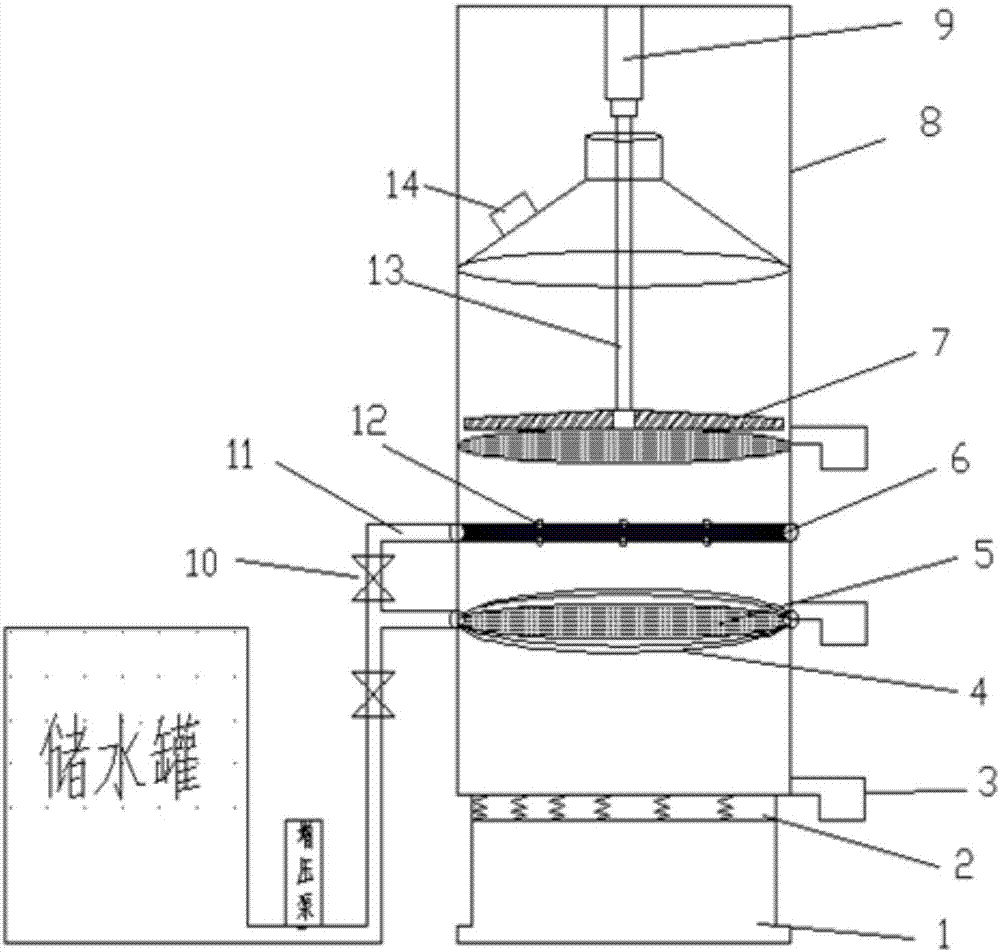

[0062] The slurry with a powder solid-liquid ratio of 10% enters the first layer of the vibrating screen from the feed port. The first layer of the vibrating screen is equipped with a feeder device. Distributed on the sieve of the first layer, and through the continuous material separation process, the materials gathered together are stirred to increase the contact area between the powder particles and the sieve; after the powder particles are sieved on the first layer, it is suitable for Conditional small particles enter the second layer through the filter screen of the first layer, and the reversing flushing device installed on the second layer adjusts the steering angle of 0±45° according to the layer height of the vibrating screen. The flushing water pressure is 0.1mpa, and the turning angle is ±30° to backwash the first layer of filter, and the particles blocked in the mesh are backwashed out of the mesh to improve the pass rate of the first layer of filter; because the fl...

Embodiment 2

[0064] The slurry with a powder solid-liquid ratio of 20% enters the first layer of the vibrating screen from the feed port. The first layer of the vibrating screen is equipped with a feeder device. Distributed on the screen of the first layer, and through the continuous material distribution process, the collected materials are stirred to increase the contact area between the powder particles and the screen; after the powder particles are screened on the first layer, Small particles with suitable conditions enter the second layer through the first layer of filter screen, and the reversing flushing device installed on the second layer adjusts the steering angle 0±45° according to the layer height of the vibrating screen, and the reversing flushing device operates at 1 time / min , The flushing water pressure is 0.15mpa, and the angle of rotation is ±40° to backwash the first layer of filter, and the particles blocked in the mesh are backwashed out of the mesh to improve the pass ...

Embodiment 3

[0066] The slurry with a powder solid-liquid ratio of 35% enters the first layer of the vibrating screen from the feed port. The first layer of the vibrating screen is equipped with a feeder device. Distributed on the screen of the first layer, and through the continuous material distribution process, the collected materials are stirred to increase the contact area between the powder particles and the screen; after the powder particles are screened on the first layer, Small particles with suitable conditions enter the second layer through the first layer of filter screen, and the reversing flushing device installed on the second layer adjusts the steering angle 0±45° according to the layer height of the vibrating screen, and the reversing flushing device operates at 2 times / min , The flushing water pressure is 0.2mpa, and the turning angle is ±45° to backwash the first layer of filter, and the particles blocked in the mesh are backwashed out of the mesh to improve the pass rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com