Flotation column special for floating fine flake graphite

A fine scale and flotation column technology, applied in flotation, solid separation, etc., can solve the problems of low flotation efficiency, large feeding kinetic energy, small swirl force field at the bottom of the lower column, etc., and achieve swirl separation Good effect, low operating cost, large swirl force field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

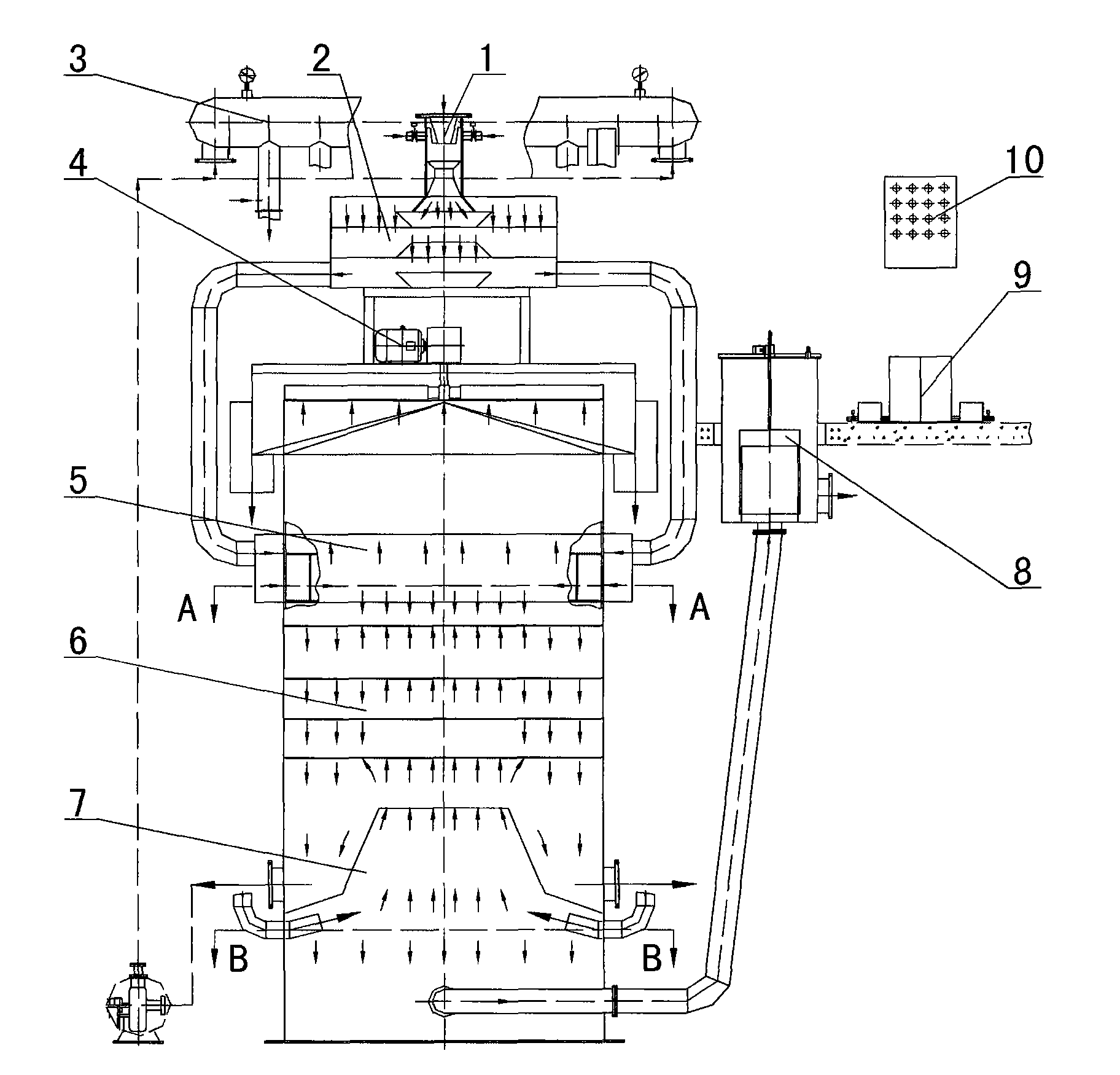

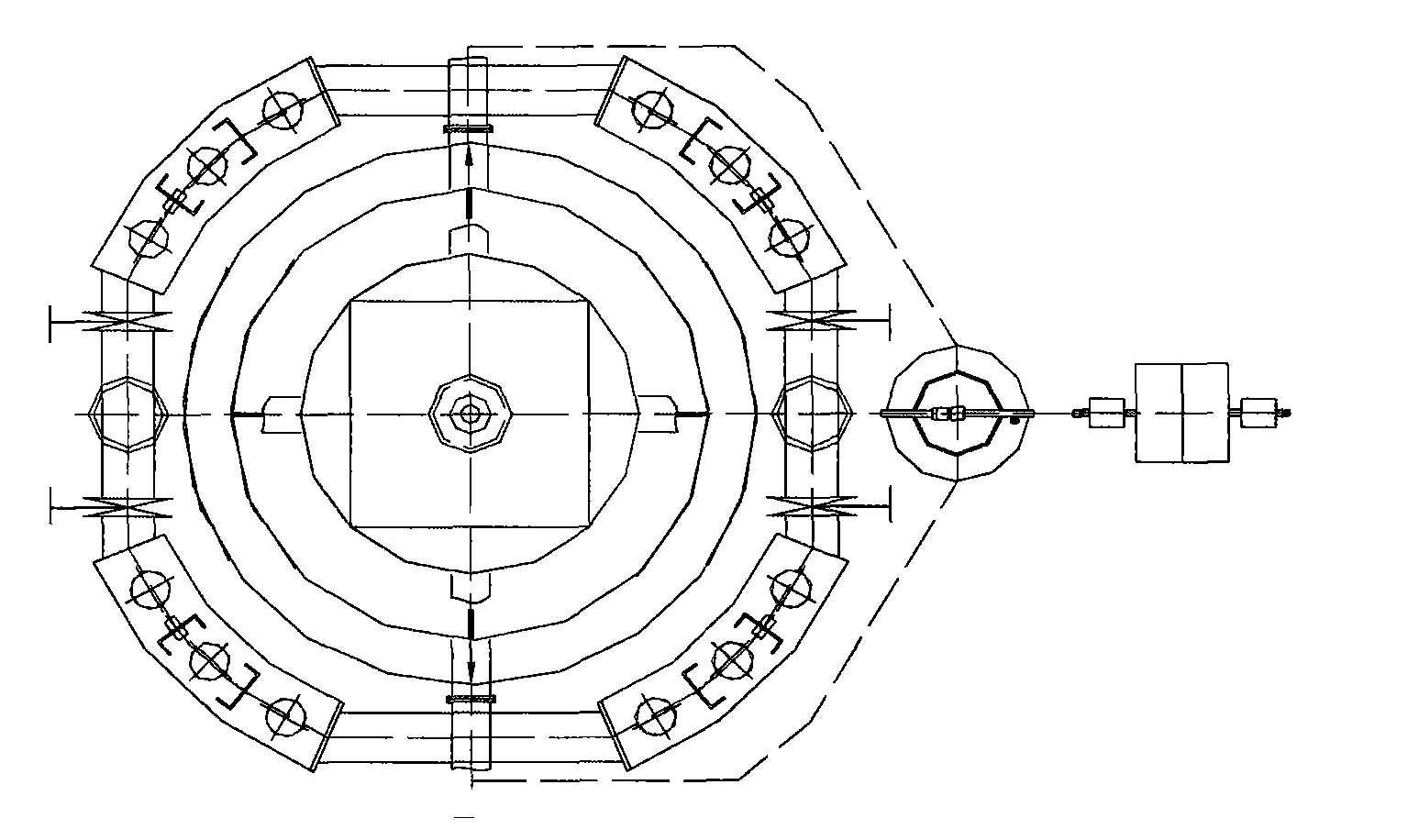

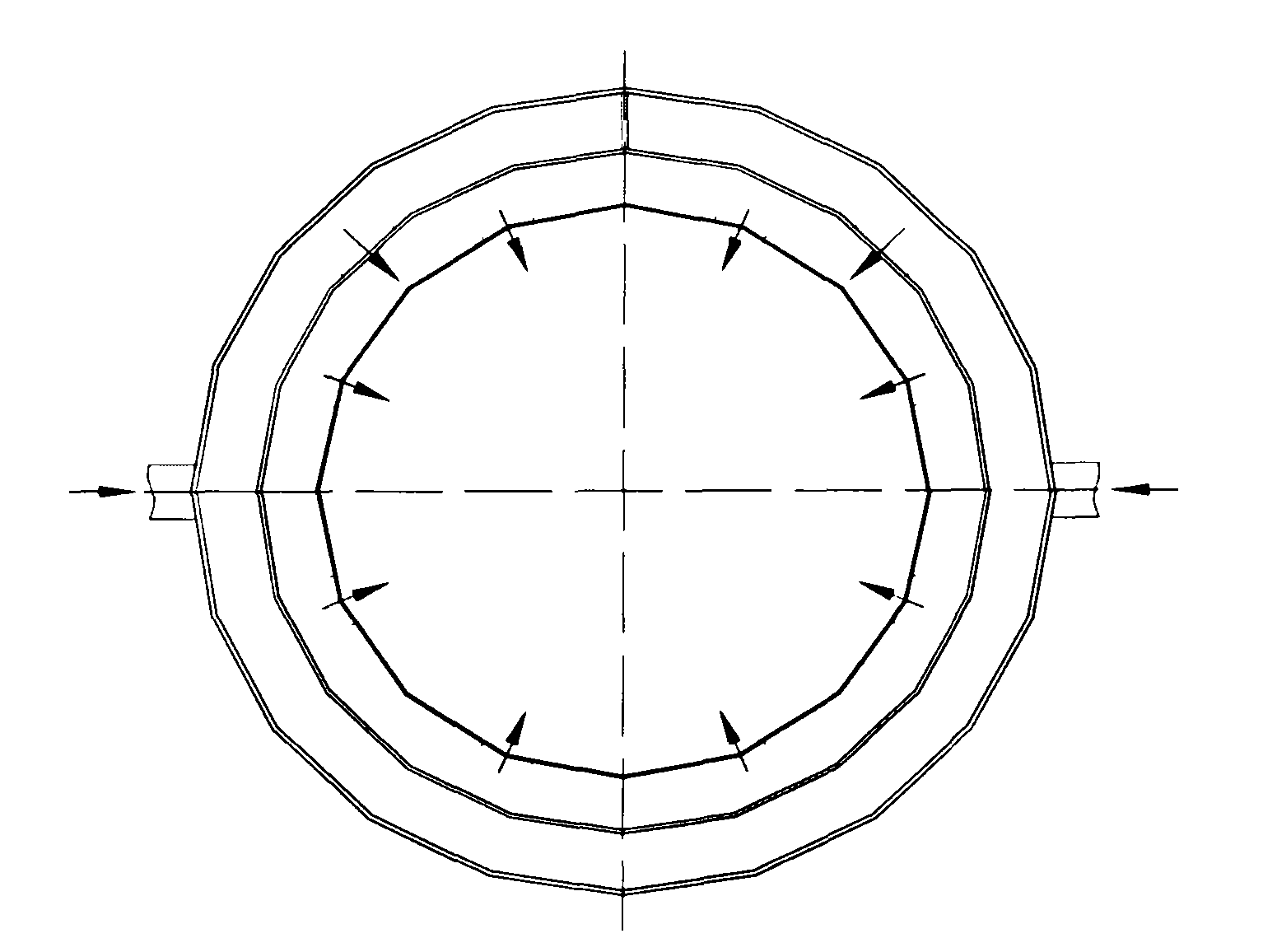

[0034] see figure 1 , figure 2 , image 3 , Figure 4 .

[0035] The ore pulp is transported to the mixing device 1 through the pump, and the amount of air, the amount and the ratio of the two chemicals are adjusted through the PLC control box 10, so that the gas, chemicals and the raw ore pulp are fully mixed and then sprayed into the static mineralizer 2, so that the gas, The agent and raw ore pulp are further fully mixed to improve the mineralization effect of raw ore and reduce the kinetic energy of raw ore feeding. The mineralized ore slurry flows into the static feeding device of the upper column 5 through two symmetrical discharge pipes, and passes through the outer feeding groove and the inner diverging groove to prolong the mineralization time of the selected material and stabilize the feeding. Improved flotation performance. The ore pulp passes through the multiple outlets evenly distributed on the inside of the splitter tank, so that the selected materials are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com