Self-gas supply mixed fly ash multistage flotation separation system

A hybrid, fly ash technology, used in flotation, solid separation, etc., can solve the problems of unsatisfactory flotation effect and increased manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

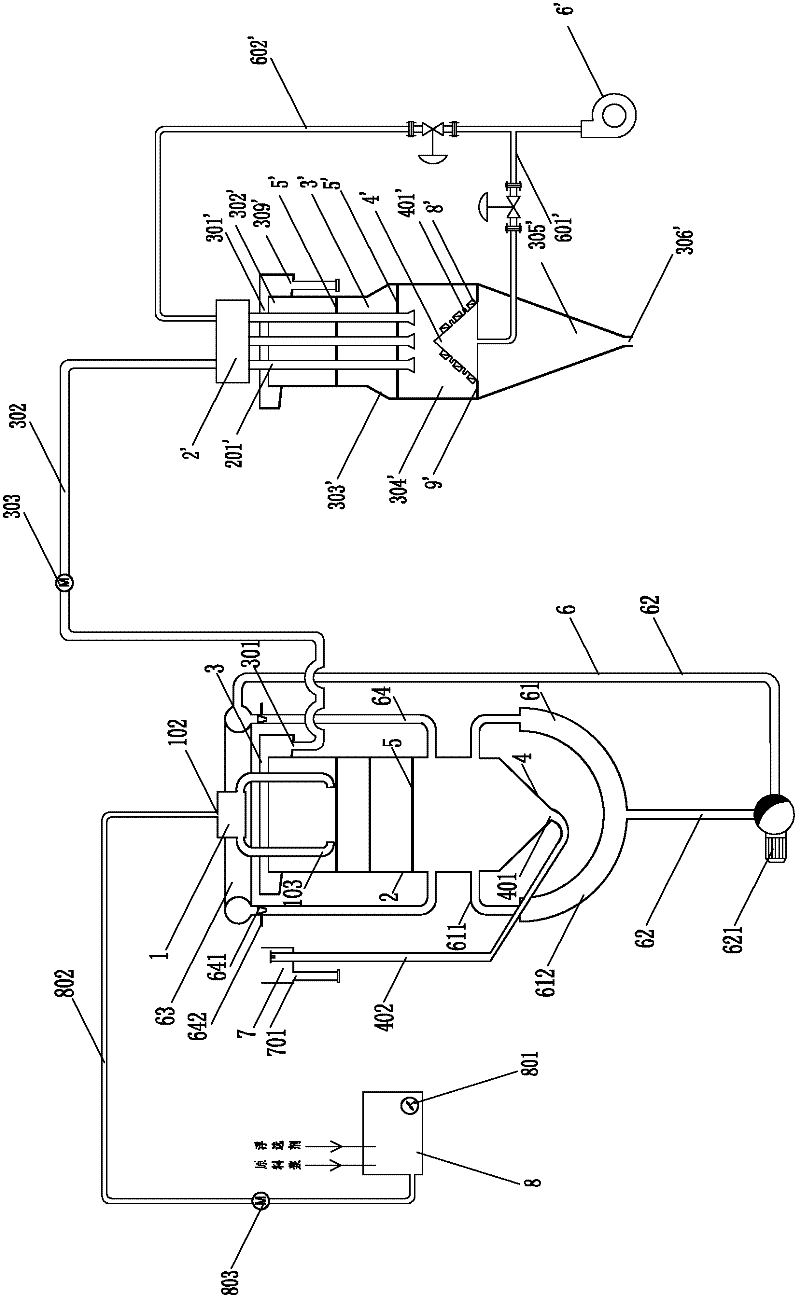

[0052] Such as figure 1 As shown, Example 1 of the present invention includes two flotation separation devices.

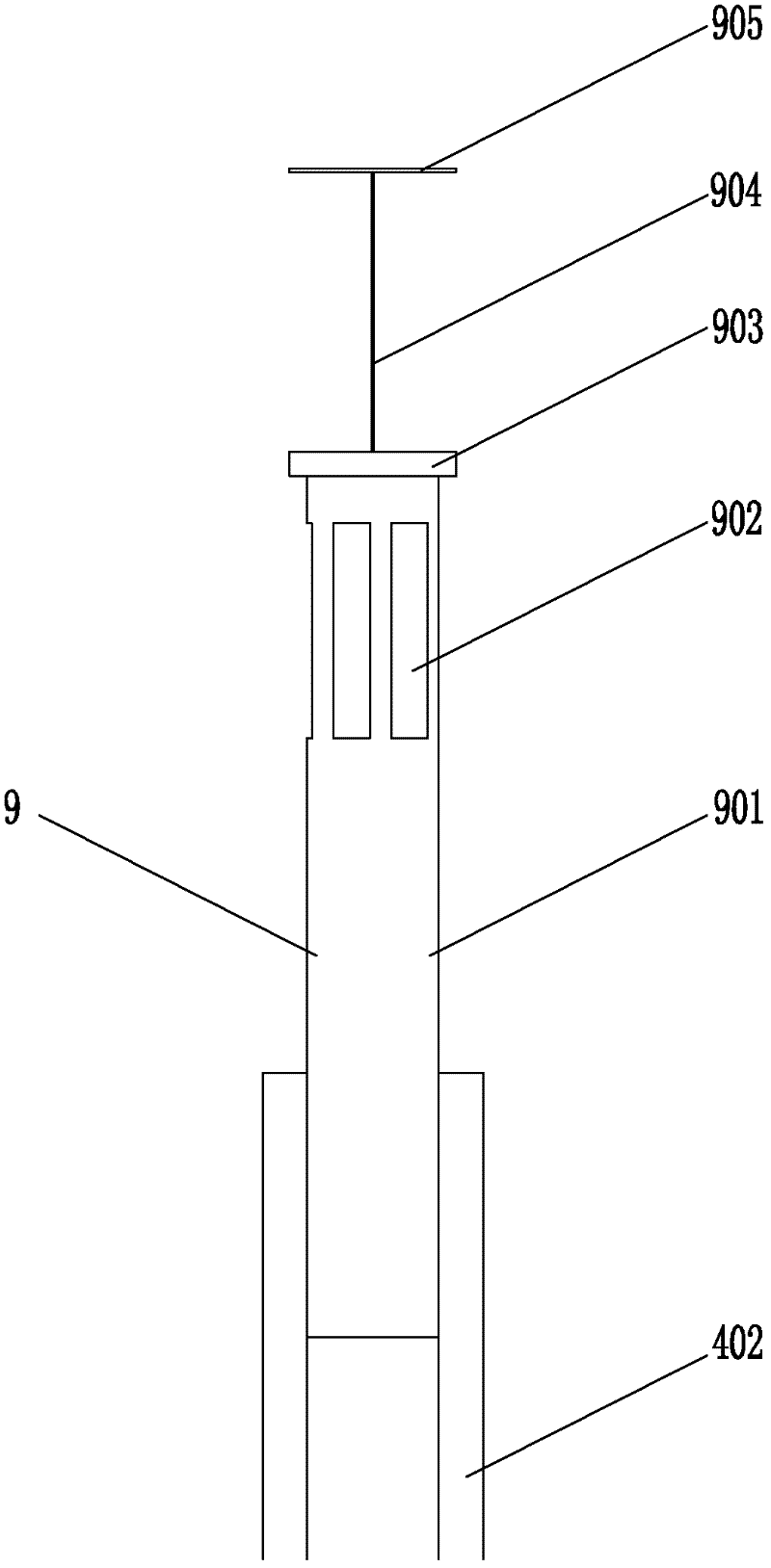

[0053] Wherein, the first flotation separation device is a self-supply type flotation separation device, which includes: a storage device 8, a distribution device 1, a vertical cylinder 2, an overflow collection section 3, a tail ash collection section 4, Multi-layer flotation plate 5, circulation device 6, tail ash box 7, liquid level adjustment device 9.

[0054] Wherein, the material storage device 8 is provided with a stirring device 801 for fully stirring the fly ash raw material slurry and the flotation agent. The lower part of the material storage device 8 is provided with a feeding pipeline 802 on which a slurry pump 803 is arranged, and the feeding pipeline 802 leads to the distribution device 1 .

[0055] The cylinder body 2 is provided with multiple layers of flotation plates 5 (for example, 3 layers) arranged at intervals.

[0056] The overflow colle...

Embodiment 2

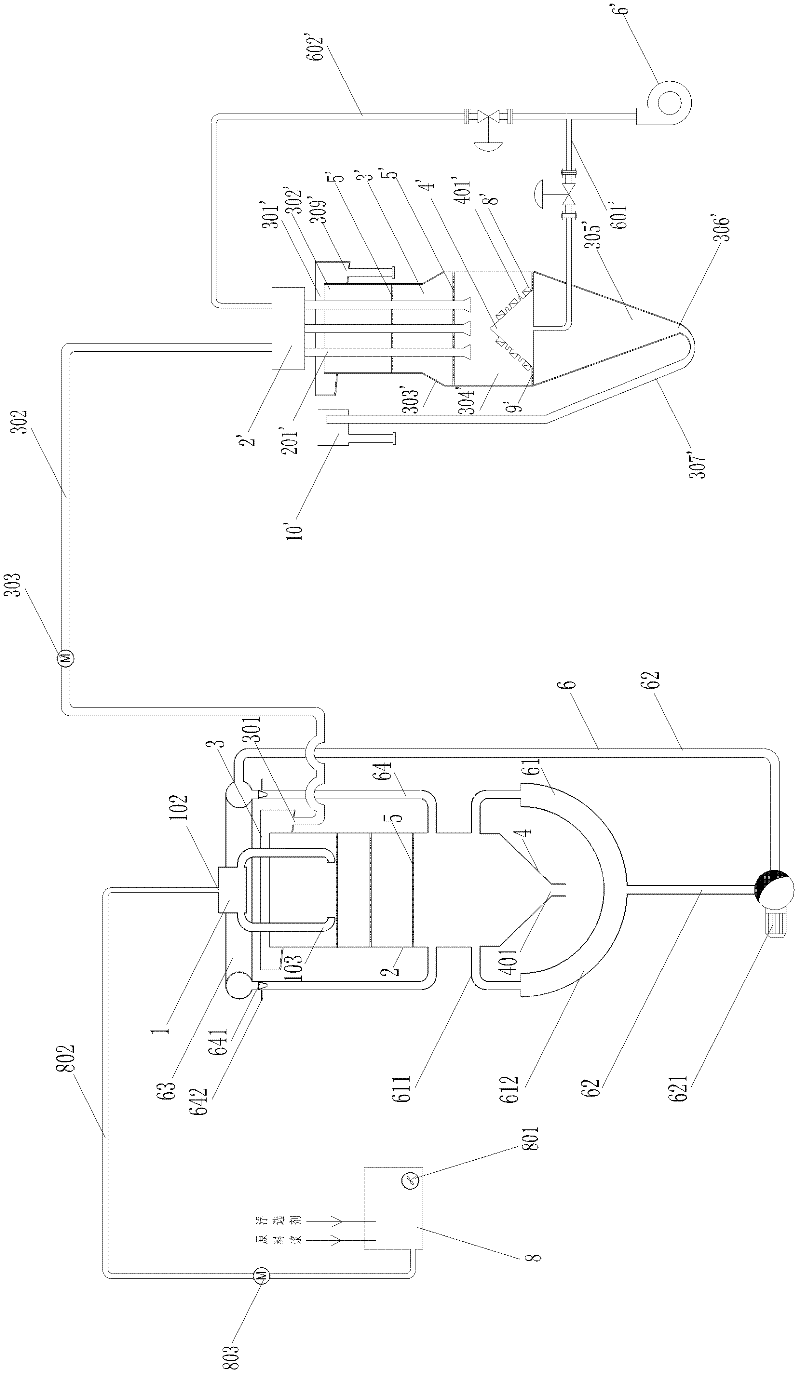

[0076] Such as image 3 As shown, embodiment 2 of the present invention is similar to embodiment 1, and its difference is: 1, the first flotation separation device is not provided with tail ash pipeline 402, liquid level regulating device, tail ash box 7; 2, the second In the flotation separation device, the tail ash outlet 306' is connected to the tail ash pipeline 307', and the end of the tail ash pipeline 307' is provided with a tail ash box 10' and a liquid level adjustment device, where the tail ash pipeline, the liquid level adjustment device, the tail ash The structure and connection relationship of the gray box are the same as before, and will not be repeated here.

Embodiment 3

[0078] Such as Figure 4 As shown, embodiment 3 of the present invention is similar to embodiment 2, and its difference is: the second flotation separation device also comprises stocker 1 ', and the discharge pipeline 302 of the first flotation separation device leads to this storage Material device 1'. Stirring device 101' is arranged in material storage device 1', and feeding pipeline 102' is arranged at the lower part of material storage device 1', and slurry pump 103' is arranged on feeding pipeline 102', and the feeding pipeline 102' leads to distribution device 2 '.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com