Nuisanceless oredressing additive as well as preparation method and application thereof

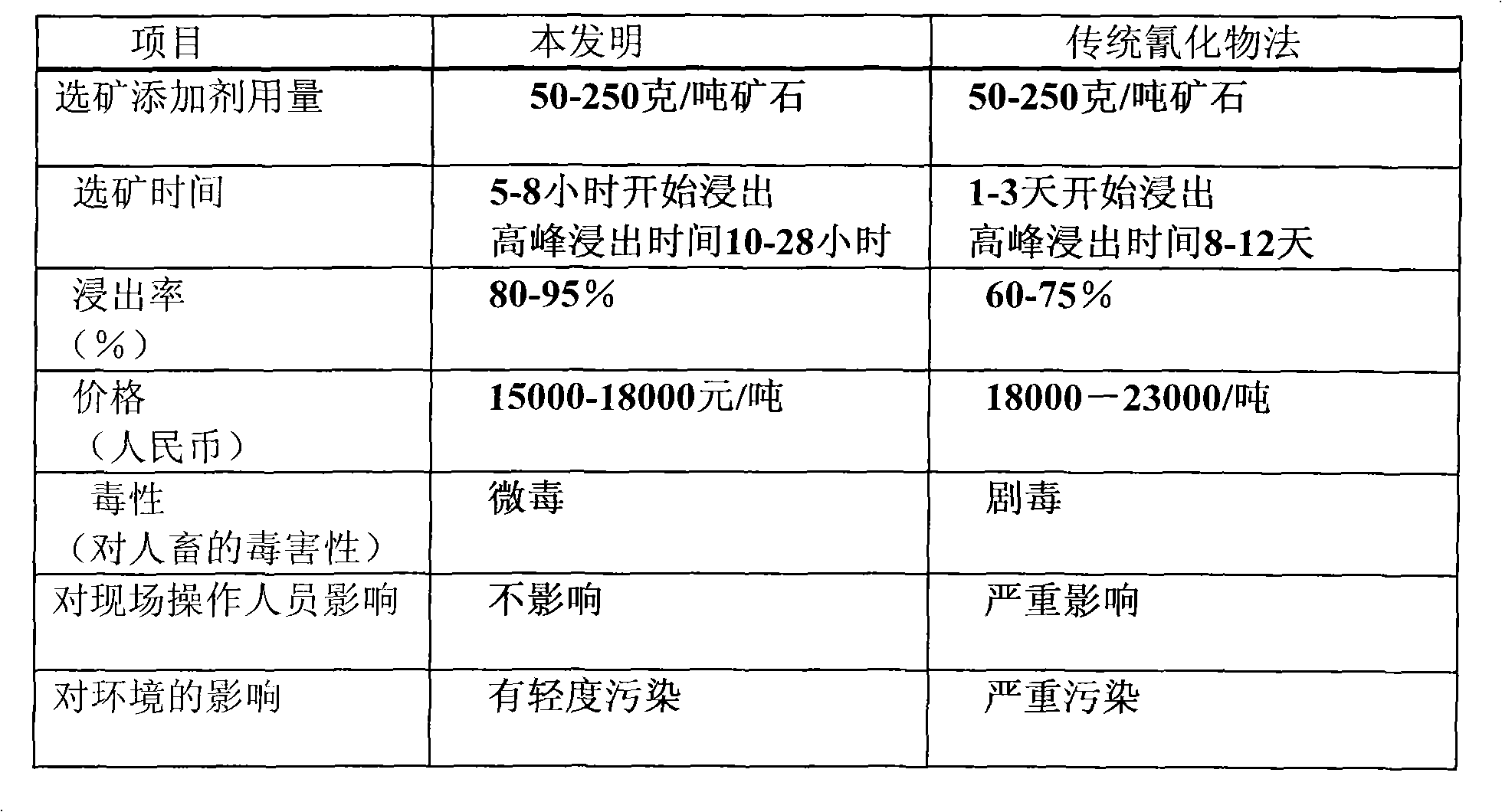

An additive and ore technology, applied in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of highly toxic cyanide pollution, high price, and high production costs, and achieve the effects of environmental protection, stable medicinal properties and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, get 5 kilograms of yellow blood salt, 10 kilograms of sodium hydroxide, 10 kilograms of sodium carbonate, 15 kilograms of urea, after the yellow blood salt is heated to molten state first, then add sodium hydroxide, sodium carbonate, urea and comprehensively heat to 600-1000°C, after reaching the molten state, cool directly to normal temperature or put it in a mold, cool to normal temperature, demould, and get the mineral processing additives of gold oxide, silver oxide and copper oxide in block shape.

Embodiment 2

[0020] Embodiment 2, get 6 kilograms of yellow blood salt, 15 kilograms of sodium hydroxide, 20 kilograms of sodium carbonate, 25 kilograms of urea, after the yellow blood salt is heated to molten state first, then add sodium hydroxide, sodium carbonate, urea and comprehensively heat to 600-1000°C, after the material reaches a molten state, it is directly cooled to normal temperature or placed in a mold, cooled to normal temperature, and demolded to obtain block-shaped mineral processing additives of gold oxide, silver oxide and copper oxide.

Embodiment 3

[0021] Embodiment 3, get 8 kilograms of yellow blood salt, 12 kilograms of sodium hydroxide, 19 kilograms of sodium carbonate, 30 kilograms of urea, after the yellow blood salt is heated to molten state first, then add sodium hydroxide, sodium carbonate, urea and comprehensively heat to 600-1000°C, after the material reaches a molten state, it is directly cooled to normal temperature or placed in a mold, cooled to normal temperature, and demolded to obtain block-shaped mineral processing additives of gold oxide, silver oxide and copper oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com