Method for preparing praziquantel

A technology of praziquantel and pyridine, applied in the field of preparation of praziquantel, can solve the problems of complicated reaction operation, harsh reaction conditions, high price and the like, and achieve the effects of shortening the reaction process, mild reaction conditions and improving the total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

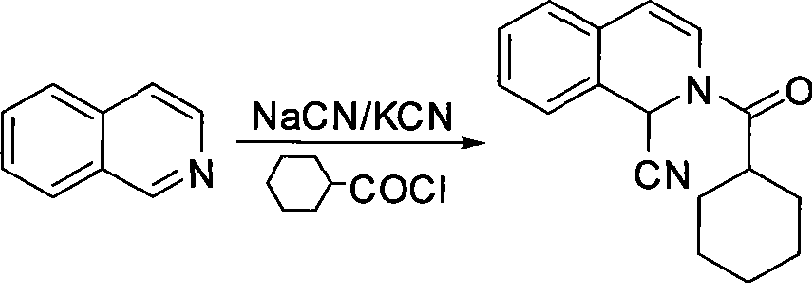

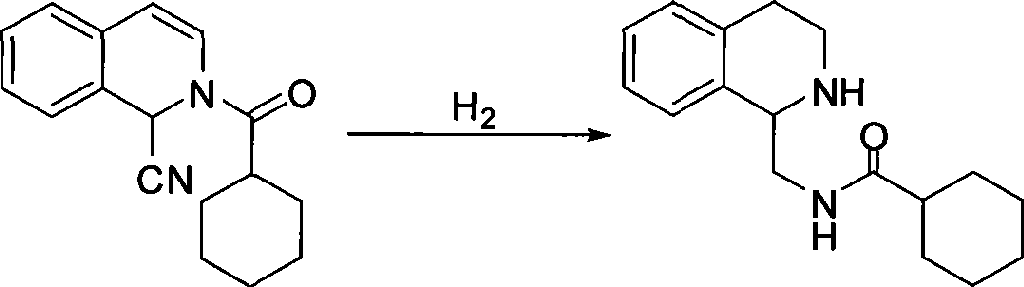

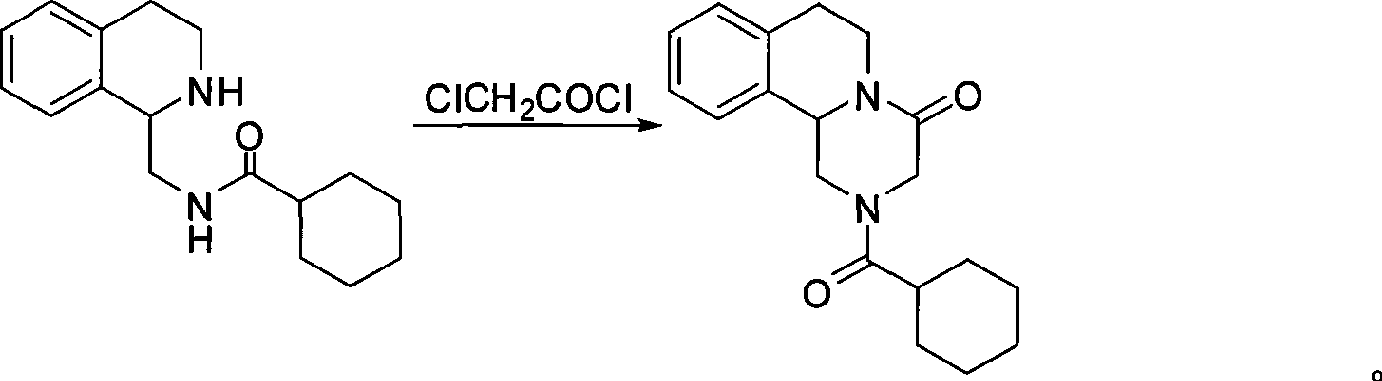

Method used

Image

Examples

Embodiment 1

[0026]

[0027] Add isoquinoline (12.9g, 0.1mol), pyridine (0.4g, 5mmol) and sodium cyanide (5.9g, 0.12mol), then add water (300ml), 1,2-dichloroethane (300ml), stir well and cool to -20°C with ice-salt water bath, then slowly add benzoyl chloride (16.2g, 0.11mol ), keep the temperature of the reaction mixture not exceeding -15°C during the dropwise addition, continue to stir the reaction at 0°C for 4 hours after the dropwise addition, then remove the ice-salt water bath, slowly rise to room temperature, then add dichloromethane (300ml ), separated the organic phase, dried with anhydrous sodium sulfate, filtered to remove the desiccant, and concentrated under reduced pressure to obtain a yellow solid as the first step product (24.6g). The yield was 92.5%. The melting point was 125-127°C.

[0028]

[0029] In the high-pressure hydrogenation reactor, add the first step product (26.6g, 0.1mol) and anhydrous methanol (600ml), then add the Ru / C catalyst (1.3g) containing 5% r...

Embodiment 2

[0033] Other steps are identical with embodiment 1, just the preparation method of A step is as follows:

[0034] Add isoquinoline (12.9g, 0.1mol), pyridine (0.4g, 5mmol) and sodium cyanide (5.4g, 0.11mol), then add water (300ml), 1,2-dichloroethane (300ml), stir well and cool to -20°C with an ice-salt water bath, then slowly add benzoyl chloride (17.7g, 0.11mol ), keep the temperature of the reaction mixture not exceeding -15°C during the dropwise addition, continue to stir the reaction at 0°C for 4 hours after the dropwise addition, then remove the ice-salt water bath, slowly rise to room temperature, then add dichloromethane (300ml ), separated the organic phase, dried with anhydrous sodium sulfate, filtered to remove the desiccant, concentrated under reduced pressure to obtain a yellow solid as the first step product (24.3g), yield 91.4%.

Embodiment 3

[0036] Other steps are identical with embodiment 1, just the preparation method of B step is as follows:

[0037] In the high-pressure hydrogenation reactor, add the first step product (26.6g, 0.1mol) and anhydrous methanol (650ml), then add the Ru / C catalyst (1.3g) containing 5% ruthenium, stir the rear airtight reactor, Pass in hydrogen until the hydrogen pressure is 4MPa, then raise the temperature to 40°C, stir and react for 6 hours, ventilate after the reaction until it reaches normal pressure, cool to room temperature, filter and recover the catalyst, concentrate the filtrate under reduced pressure and distill off anhydrous methanol, The solid precipitated, was collected and dried to obtain the second-step product (25.1 g), with a yield of 92.3%. The next step reaction could be carried out directly without further purification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com