Novel preparation method of insensitive explosive TATB

A new type of explosive technology, which is applied in the field of new preparation of insensitive explosive TATB, can solve the problems of expensive raw materials, harsh step conditions, and high overall cost, and achieve the effect of mature synthesis process, simple synthesis route, and reduced economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

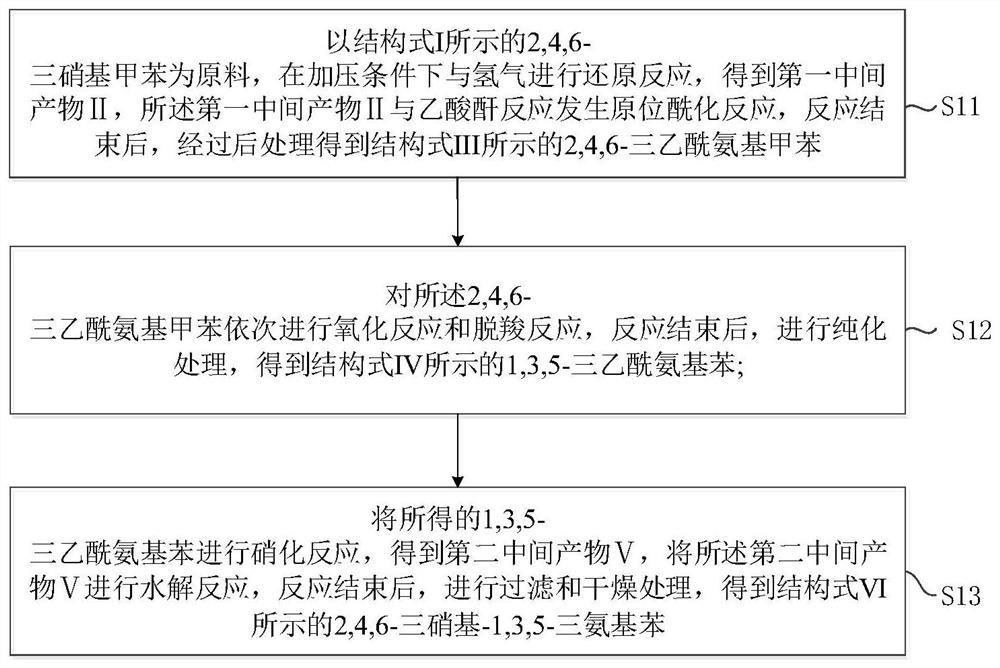

Method used

Image

Examples

Embodiment 1

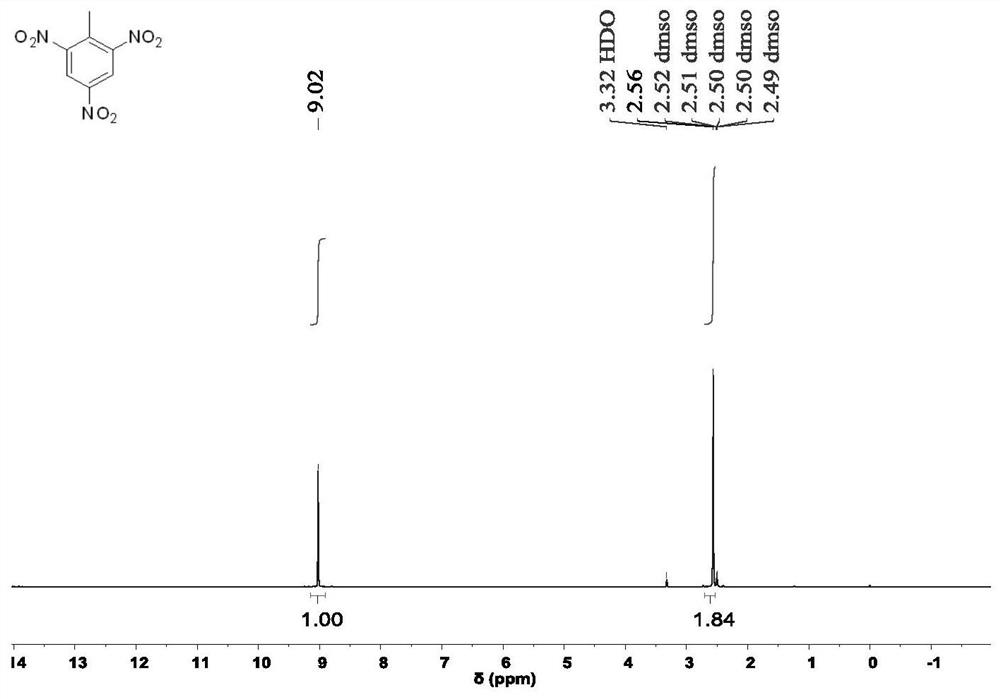

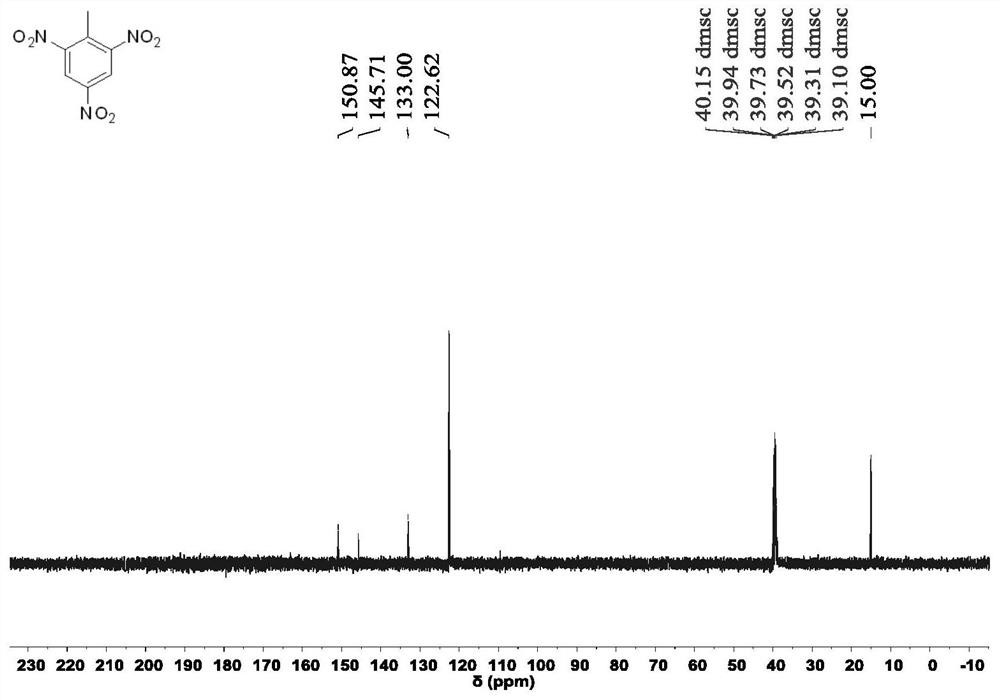

[0058] Step 1: Preparation of 2,4,6-triacetamidotoluene.

[0059] The reduction reaction and the in-situ acylation reaction are combined in the same system: take 2,4,6-trinitrotoluene I (TNT, 3.4g, 0.015mol, 1eq) and dissolve it in ethyl acetate (30ml) / acetic anhydride ( 25ml, 0.25mol, 17eq) in the mixed solution, obtain TNT solution, drop into Pd / C catalyst (5wt%, 0.3g), transfer in the high-pressure stirred reactor, vacuumize the high-pressure stirred reactor, fill with nitrogen, repeat Finally, vacuumize to ensure that there is no air residue, and continue to feed hydrogen for high-pressure (0.6MPa) reduction reaction and in-situ N-acetylation reaction at room temperature. The reaction lasts for 4 hours. After the reaction, a deep red solution and Pd / C Catalyst, the post-treatment steps are: after filtering out the Pd / C catalyst (the specific process is: first filter the reaction solution after the reaction, then wash the filter residue with 70°C preheated absolute ethanol ...

Embodiment 2

[0098] Step 1: Preparation of 2,4,6-triacetamidotoluene.

[0099]The reduction reaction and the in-situ acylation reaction are carried out in two systems: take 2,4,6-trinitrotoluene I (TNT, 6.8g, 0.03mol, 1eq) and dissolve it in methanol (50ml) to obtain a TNT solution, and put it into Pd / C catalyst (5wt%, 0.5g), transferred to the high-pressure stirred reactor, vacuumize the high-pressure stirred reactor, fill with nitrogen, repeat several times, finally vacuumize to ensure that there is no air residue, fill with hydrogen to make the pressure gauge display When the pressure reaches 0.8MPa, carry out the high-pressure hydrogenation reaction at room temperature. During the period, when the reading on the pressure gauge drops to 0.2MPa, the reaction is temporarily stopped, and the hydrogen gas is introduced to make the pressure rise to 0.8MPa. The aeration operation is repeated 4 to 5 times in total. Continued for 3 hours, after the end of the reaction, a reddish-brown solution ...

Embodiment 3

[0112] Step 1: Preparation of 2,4,6-triacetamidotoluene.

[0113] Dissolve 2,4,6-trinitrotoluene (TNT, 3.4g, 0.015mol, 1eq) in acetonitrile (25ml) to obtain a TNT solution, put into Pd / C catalyst (5wt%, 0.5g), transfer to 250ml round bottom In the flask, use a hydrogen balloon to supplement hydrogen to carry out a hydrogenation reaction under normal pressure (0.1MPa) at room temperature. The reaction lasts for 12 hours. After the reaction, a reddish-brown solution (ie 2,4,6-triaminotoluene) and Pd / C Catalyst, after filtering out the Pd / C catalyst, add acetic anhydride (10ml, 0.1mol, 6.5eq) dropwise into the solution, the reaction time is 0.5h, the reaction temperature is 25°C, a lot of white solids are precipitated, and white solids are obtained by filtration The powdery solid was washed with ethyl acetate for 3-5 times, and dried in a vacuum oven at 60°C to obtain 2,4,6-triacetamidotoluene (5.2 g, yield 65.7%).

[0114] In the embodiment of the present invention 3, the proto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com