Method for synthesizing deuterated tazobactam

A technology of tazobactam and its synthesis method, which is applied in the field of drug synthesis, can solve the problems of easy combustion, decomposition and explosion, harsh reaction conditions, and generally low yield, and achieve long action time, short synthesis steps, and excellent effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

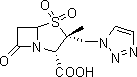

Image

Examples

Embodiment 1

[0018] Add 2ml deuterated dimethyl sulfoxide to the reactor, and add 0.4mmol 2β-azidomethylpenicillanic acid-1β-oxide, 0.57mmol propiolic acid, 0.07mmol cuprous iodide and Add 0.14 mmol of sodium ascorbate to the solvent, stir and react at room temperature for 16 hours, extract with ethyl acetate after the reaction is completed, wash the organic layer with saturated brine, dry over anhydrous sodium sulfate, and filter, evaporate the solvent under reduced pressure to obtain the crude product , using ethyl acetate and petroleum ether at a volume of 1:2 to perform column chromatography to obtain deuterated tazobactam with a yield of 85%. The H NMR spectrum of deuterated tazobactam is: 1 H-NMR (500 MHz, CDCl 3 ): δ = 1.32(3H,s), 3.29(1H,dd), 3.70(1H,dd), 4.76(1H,s), 4.9(1H,dd), 5.16(1H,m), 5.25(1H, dd), 7.78(0.01H, s), 8.08(0.01H, s).

Embodiment 2

[0020] Add 2ml of deuterated dimethyl sulfoxide to the reactor, and add 0.37mmol 2β-azidomethylpenicillanic acid-1β-oxide, 0.55mmol propiolic acid, 0.07mmol cuprous iodide, 0.14mmol sodium ascorbate and 0.19mmol triethylamine were added to the solvent, stirred and reacted at 60°C for 3 hours, extracted with ethyl acetate after the reaction was completed, the organic layer was washed with saturated brine, dried over anhydrous sodium sulfate, and decompressed The crude product was obtained by distilling off the solvent, which was filtered and subjected to column chromatography with ethyl acetate and petroleum ether at a volume of 1:5-1:3 to obtain deuterated tazobactam with a yield of 82%.

Embodiment 3

[0022] Add 2ml of deuterated dimethyl sulfoxide to the reactor, and add 0.34mmol 2β-azidomethylpenicillanic acid-1β-oxide, 0.50mmol propiolic acid, 0.02mmol cuprous iodide, 0.04mmol of sodium ascorbate and 0.17mmol of 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) were added to the solvent, stirred and reacted at 80°C for 5 hours, after the reaction was completed, rinse with acetic acid Ethyl extraction, the organic layer was washed with saturated brine, dried over anhydrous sodium sulfate, and the solvent was evaporated under reduced pressure to obtain the crude product, which was filtered and column layered with ethyl acetate and petroleum ether with a volume of 1:5-1:2 Analysis obtained deuterated tazobactam, and the yield was 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com