Method for separating and recovering valuable metals from copper anode slime

A copper anode slime, separation and recovery technology, applied to the improvement of process efficiency, element selenium/tellurium, etc., can solve the problems of poor comprehensive recovery effect, single recovered metal, low recovery rate, etc., and achieve quick results and high comprehensive recovery rate , short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

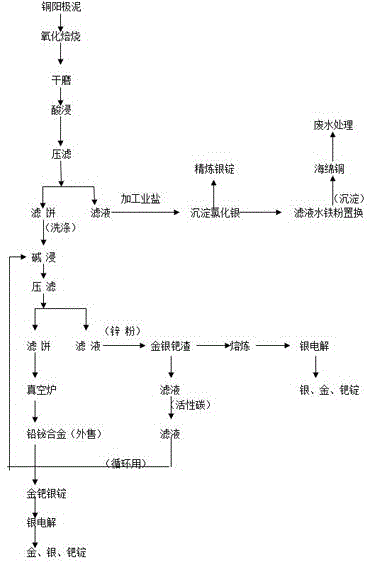

[0025] A method for separating and recovering valuable metals from copper anode slime of the present invention, the chemical composition of copper anode slime used is shown in Table 1, and its process flow chart is as follows figure 1 shown, including the following steps:

[0026] Table 1 Chemical composition of copper anode slime

[0027] the element

Au

Ag

PD

Cu

Se

Te

Pb

Bi

W / %

0.25%

5%

5%

13%

5%

1.5%

15%

7%

[0028] (1) Oxidation roasting: After the above-mentioned copper anode slime is roughly crushed, put them into material boxes (thickness: 5 cm) in batches, and send them into the oxidation tunnel kiln for oxidation roasting under sufficient air conditions, and the roasting temperature is 650 °C ℃, heat preservation for 8 hours to completely oxidize the copper anode slime. After exiting the kiln, primary soot and roasted products are obtained;

[0029] Pass the primary soot through the ...

Embodiment 2

[0038]A method for separating and recovering valuable metals from copper anode slime of the present invention, the chemical composition of copper anode slime used is shown in Table 1, and its process flow chart is as follows figure 1 shown, including the following steps:

[0039] Table 1 Chemical composition of copper anode slime

[0040] the element

Au

Ag

PD

Cu

Se

Te

Pb

Bi

3 --> W / %

0.3%

8%

4.5

10%

3%

1.0%

10%

9%

[0041] (1) Oxidation roasting: After the above-mentioned copper anode slime is roughly crushed, put them into material boxes (thickness: 5 cm) in batches, and send them into the oxidation tunnel kiln for oxidation roasting under sufficient air conditions, and the roasting temperature is 680 ℃, heat preservation for 8 hours to completely oxidize the copper anode slime. After exiting the kiln, primary soot and roasted products are obtained;

[0042] Pass the primary soot through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com