Combination technique for processing and recycling high-cyanogen high-ammonia high-salt organic waste water

A technology for organic wastewater treatment and combined processes, which is applied in water/sewage treatment, adsorbed water/sewage treatment, oxidized water/sewage treatment, etc., and can solve the problems of low removal rate, complicated production, supply, and regeneration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

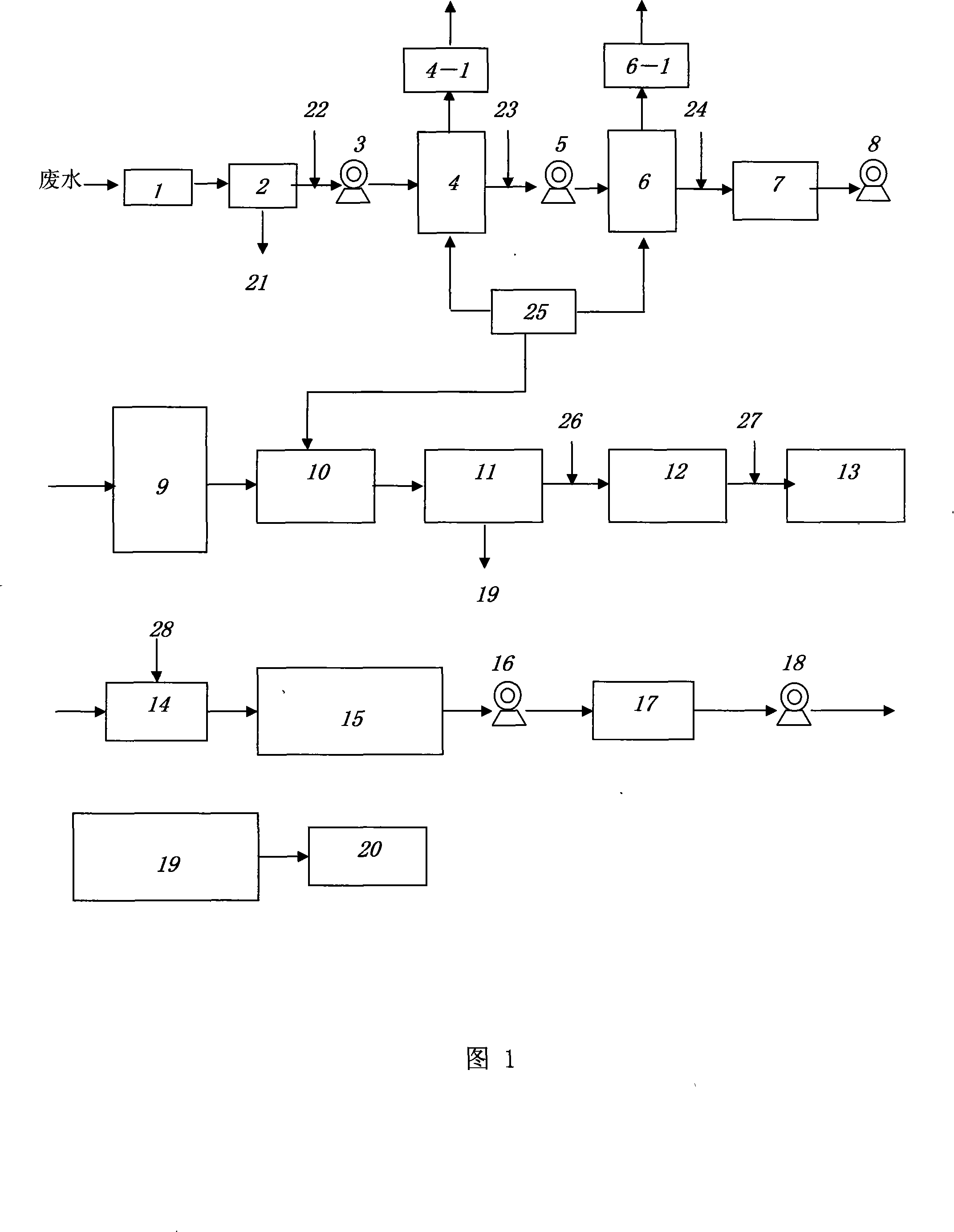

[0088] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

[0089] Degussa Sanzheng (Yingkou) Fine Chemical Co., Ltd. cyanuric chloride process waste brine (from the analysis kettle) water quality is as follows: pH value: 5 ~ 6, COD: 3500mg / L, total cyanide (calculated as CN) content is 600mg / L, ammonia nitrogen (NH 3 -N) content is 1000 mg / L, sodium formate (HCOONa): 3800-4200 mg / L, sodium chloride (NaCl): 18%-20%.

[0090] In accompanying drawing 1, cyanuric chloride waste water is sent to coarse filter 2 to filter with insulation pipe 1; Strain filter salt mud 21 is concentrated treatment separately, and coarse filter effluent is introduced into acidification decyanation pool 4 decyanation through acid-resistant pump 3, and hydrogen is discharged Cyanic acid is absorbed with alkali in the cyanogen absorber 4-1, and reclaims sodium cyanide. Add hydrochloric acid 22 before the acid-resistant pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com