A kind of decarbonation process of methionine salt saponification liquid

A technology of methionine salt and saponification solution, applied in bipolar membrane electrodialysis technology in the chemical industry, to achieve the effects of stable operation, reasonable combination and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

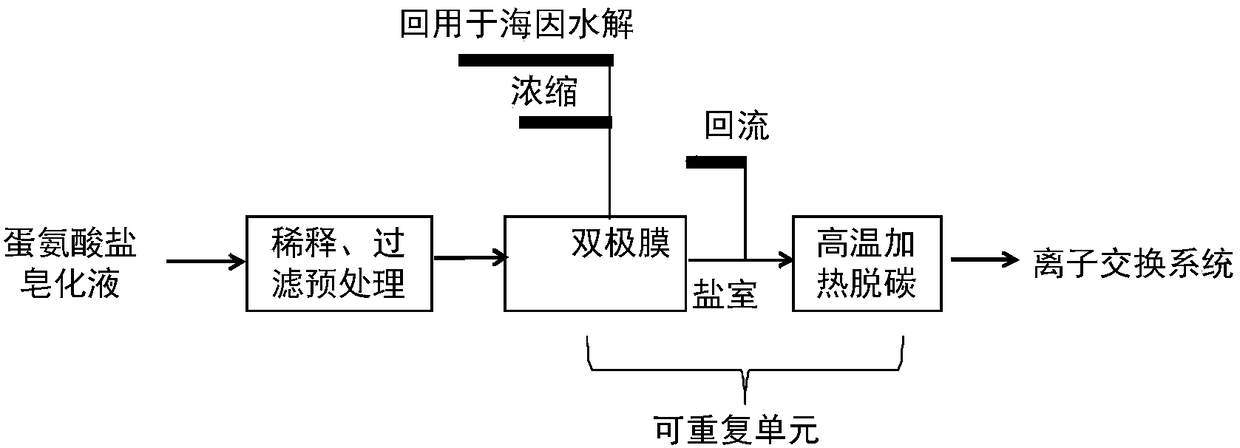

[0030] The main water components of the methionine salt saponification solution are 15wt% sodium methionine, 8wt% sodium carbonate, 1ppm organic matter, and the rest is water. Refer to attached figure 2 , at first in order to guarantee the methionine salt concentration requirement in the bipolar membrane influent water quality, the saponification liquid is diluted 0.5 times, and the sodium methioninate saponification liquid composition after dilution is mainly the sodium methioninate of 10wt%, the sodium carbonate of 5.3wt%. Then use a 5um microporous filter bag to filter the diluted saponification solution.

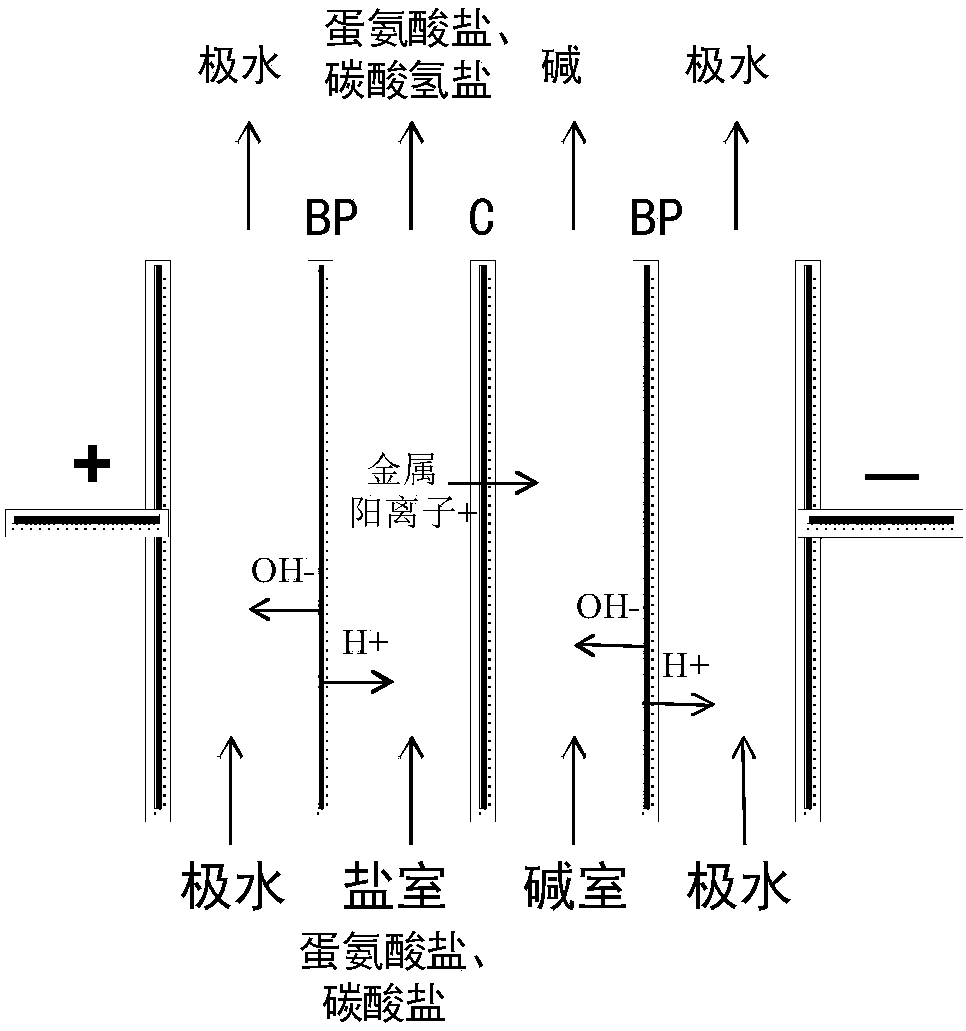

[0031] Then, the filtrate enters the bipolar membrane system, the salt chamber CO 3 2- Combining H+ produced by bipolar membrane to form HCO3 - , the cations in the saponification solution in the salt chamber enter the alkali chamber through the cation exchange membrane, and combine with the OH produced by the bipolar membrane - The corresponding bases are formed. ...

Embodiment 2

[0035] The main water components of the methionine salt saponification liquid are 16wt% sodium methionine, 10wt% sodium carbonate, 1ppm organic matter, and the rest is water. Refer to attached figure 2 Firstly, in order to ensure the methionine salt concentration requirement in the bipolar membrane influent water quality, the saponification solution is diluted 1.3 times, and the sodium methioninate saponification solution composition after dilution is mainly 7wt% sodium methioninate and 4.3wt% sodium carbonate. Then use a 5um microporous filter bag to filter the diluted saponification solution.

[0036] Then, the filtrate enters the bipolar membrane system, the salt chamber CO 3 2- Combining H+ produced by bipolar membrane to form HCO 3 - , the cations in the saponification solution in the salt chamber enter the alkali chamber through the cation exchange membrane, and combine with the OH produced by the bipolar membrane - The corresponding bases are formed. Among them, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com