Technique method for electroplating inner surfaces of gear wheel holes and dedicated equipments

A process method and electroplating process technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of shielding layer environmental pollution, complex operation procedures, and affecting the performance of coatings, so as to save equipment investment costs, simplify process steps, and improve production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

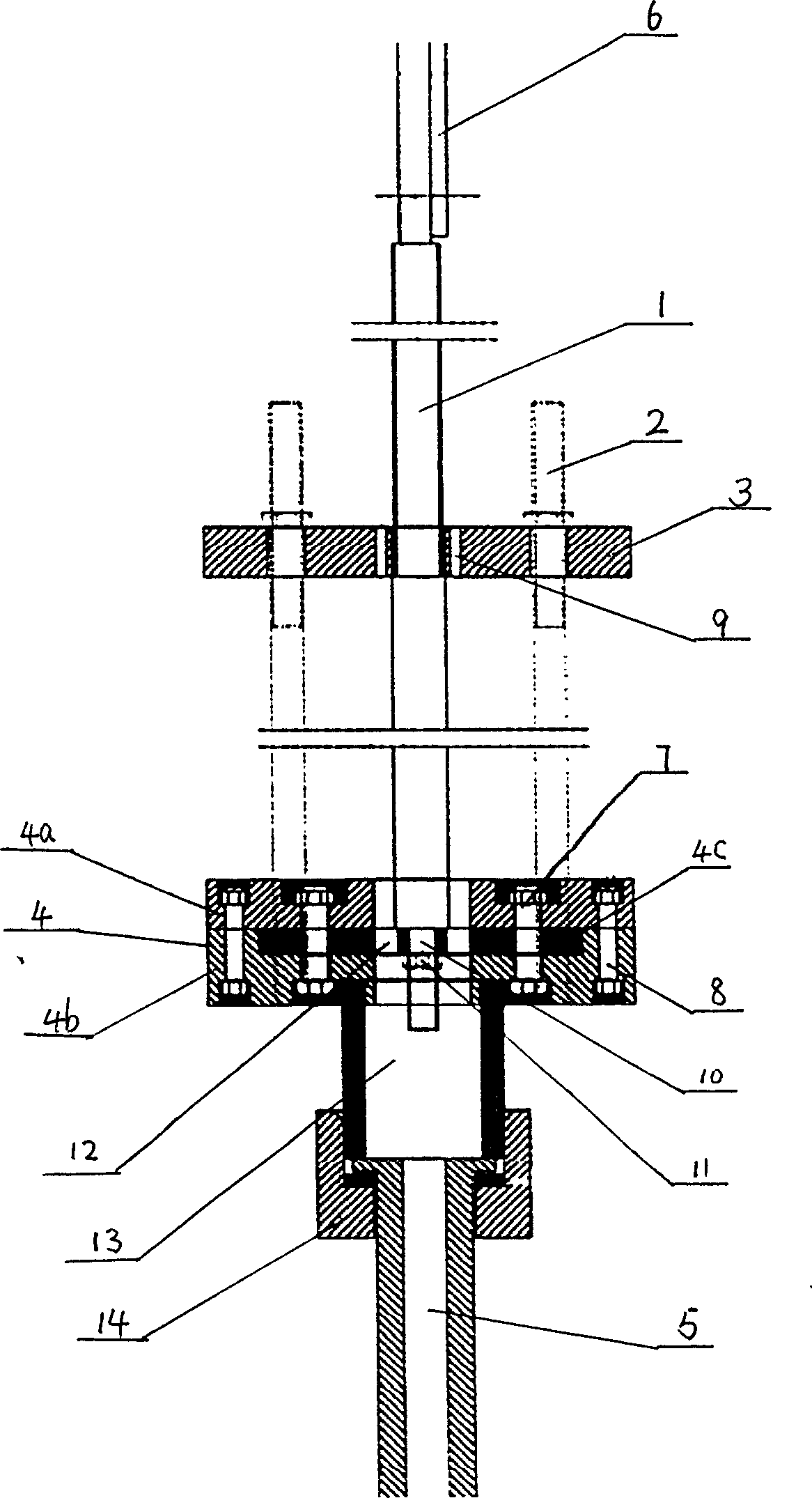

[0021] Embodiment 1: The technological process of gear inner hole surface electroplating of the present invention, its technological process comprises the following each procedure: gear is installed on the special fixture-metal cleaning agent degreasing-water washing-electrolytic degreasing-water washing-30% hydrochloric acid solution immersion Corrosion—water washing—electroplating—water washing—deionized water cleaning—drying—high temperature dehydrogenation, which is characterized in that the electroplating process adopts a bipolar electroplating method; the fixture for installing gears is not only a fixture for clamping gears, but more importantly, It is a special device for electroplating electroless plating deposition. In the electroplating process, the composition of the bipolar electroplating tin bronze bath is: cuprous cyanide 11-13 g / L, sodium stannate 21-24 g / L, sodium cyanide 45-50 g / L, sodium hydroxide 22-26 g / L.

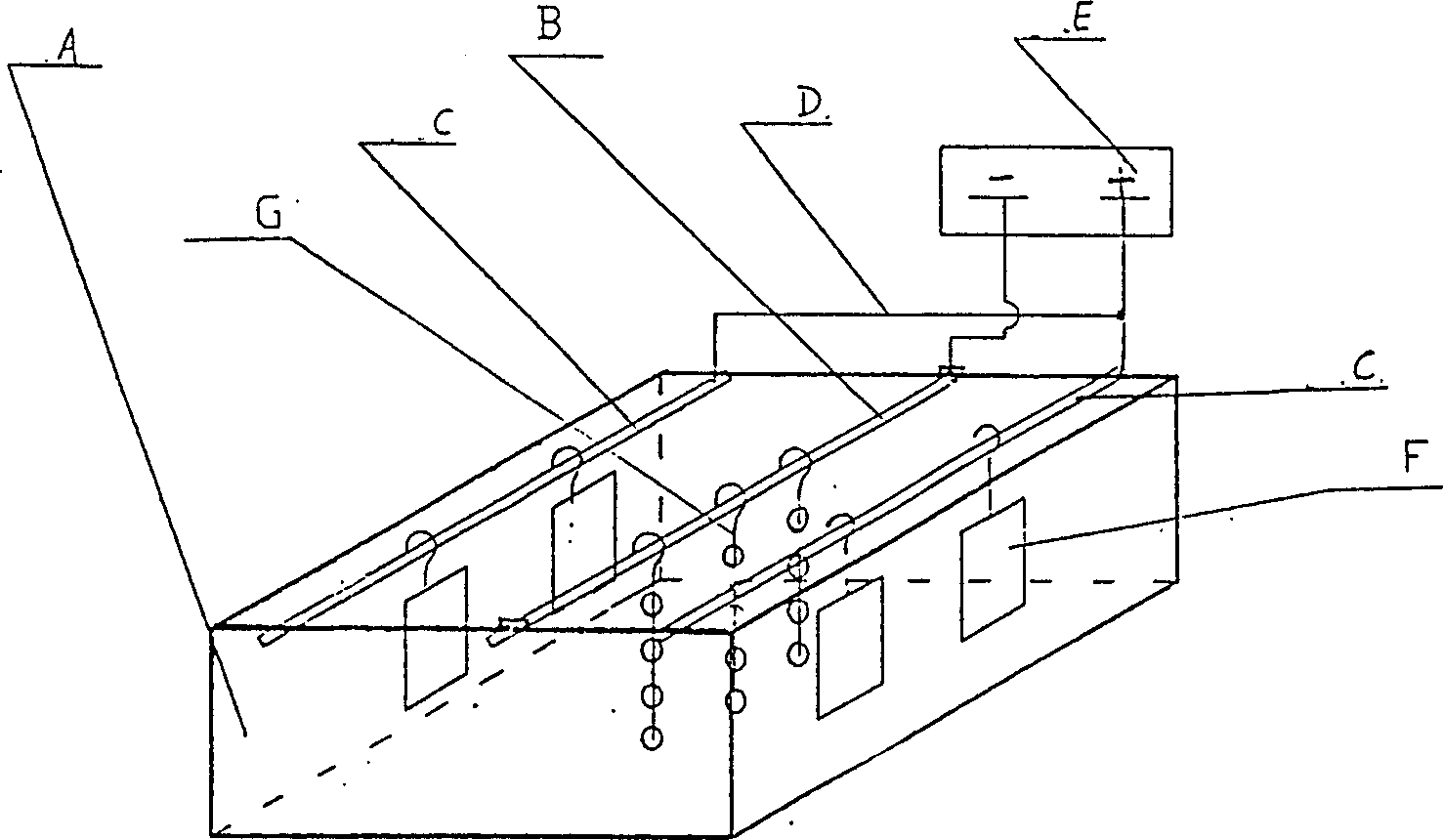

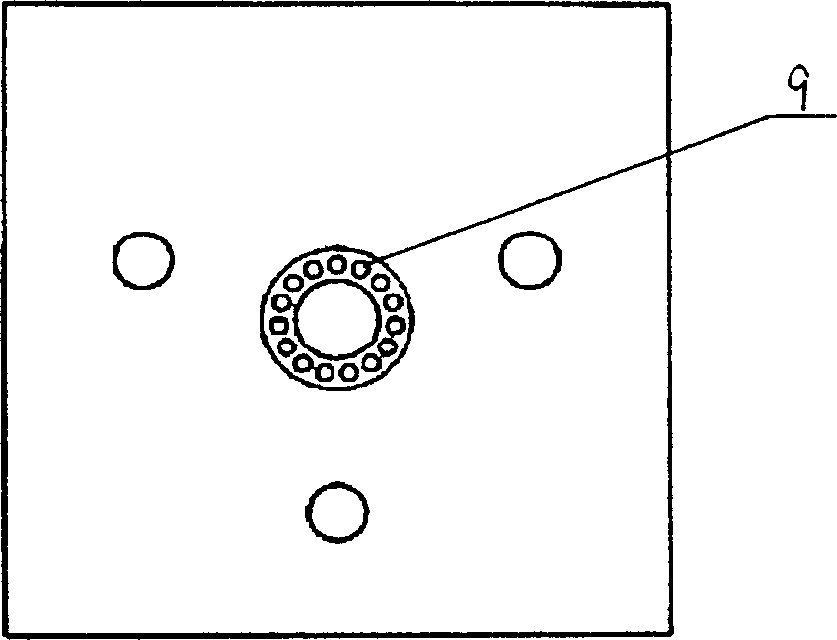

[0022] see figure 1 Schematic diagram of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com