Method for preparing methionine

A technology for methionine and mother liquor, applied in the field of methionine preparation, can solve the problems of energy consumption, increased methionine loss and production cost, low sodium sulfate, etc., and achieves the effects of low cost, no discharge of a large amount of acidic and odorous wastewater, and high separation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

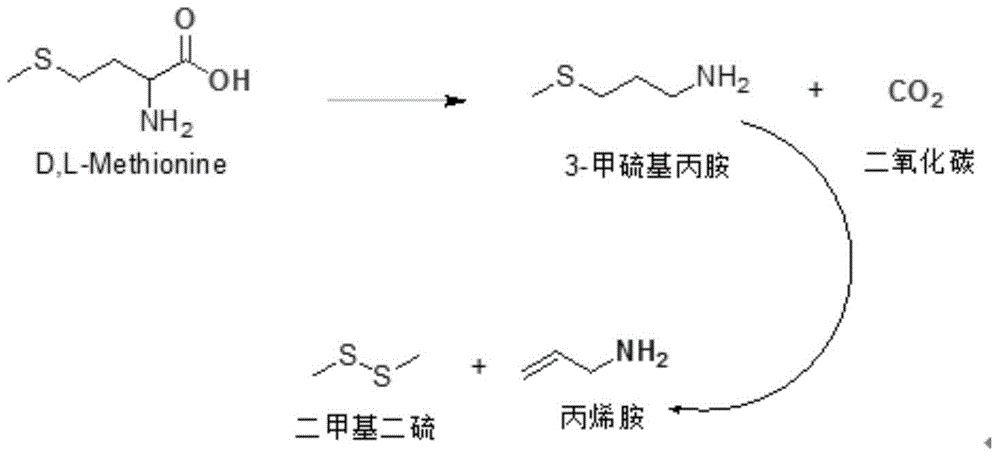

Problems solved by technology

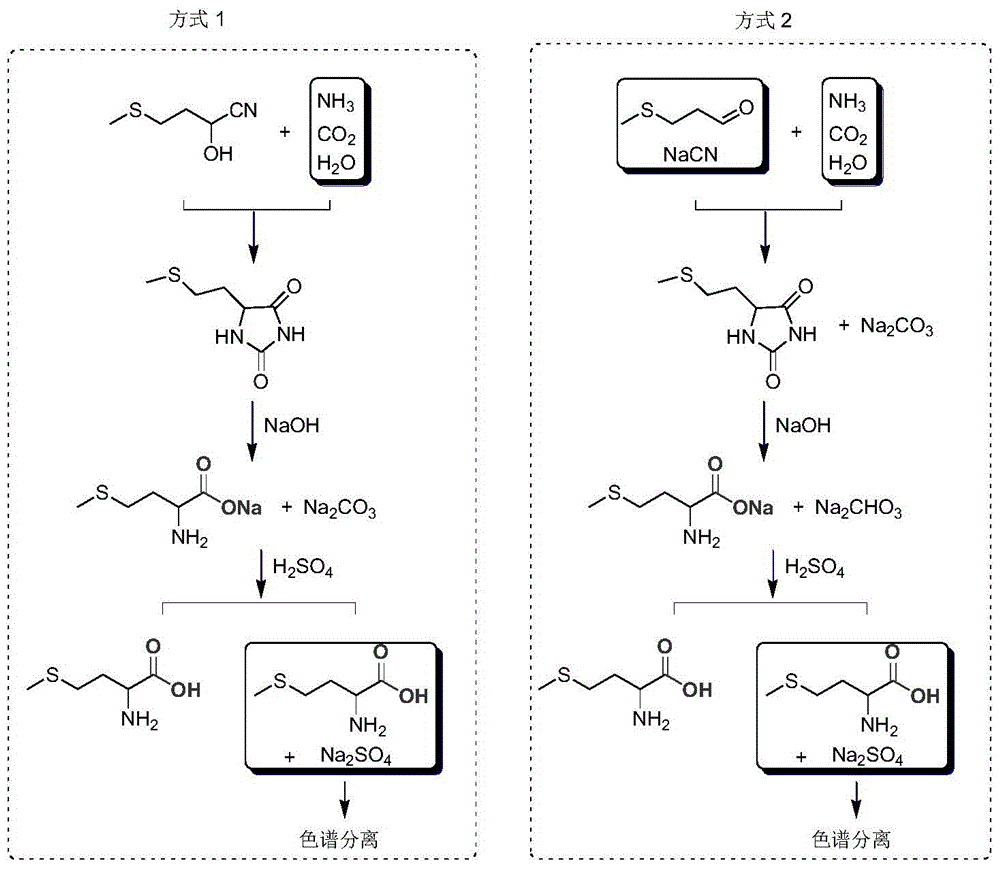

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing methionine, the specific steps are as follows:

[0030] (1) Add 1mol cyanohydrin, carbon dioxide, ammonia and 800 grams of water into the autoclave, the molar ratio of cyanohydrin to carbon dioxide and ammonia is 1:2:4; Raise the temperature to 120°C, heat and stir for 20 minutes, and raise the pressure of the reaction system to 2 MPa. After the reaction is completed, release the pressure to normal pressure, and discharge the unreacted carbon and ammonia in the reaction system to obtain a hydantoin aqueous solution;

[0031] (2) Add the hydantoin aqueous solution obtained in step (1) into the autoclave, add 1.5mol of 40% sodium hydroxide aqueous solution, immediately heat up to 178°C, keep stirring for 30 minutes, and control the pressure of the reaction system It is 2.5MPa; After the reaction is finished, it is cooled to 100° C., and the pressure is released to normal pressure, and carbon dioxide and ammonia in the reaction system are removed to ...

Embodiment 2

[0035] A method for preparing methionine, the specific steps are as follows:

[0036] (1) Add 1mol cyanohydrin, carbon dioxide, ammonia and 800 grams of water into the autoclave, the molar ratio of cyanohydrin to carbon dioxide and ammonia is 1:2:4; Raise the temperature to 120°C, heat and stir for 20 minutes, and raise the pressure of the reaction system to 2 MPa. After the reaction is completed, release the pressure to normal pressure, discharge the unreacted carbon and ammonia in the reaction system, and obtain the hydantoin aqueous solution;

[0037] (2) Add the hydantoin aqueous solution obtained in step (1) into the autoclave, add 1.5mol of 40% sodium hydroxide aqueous solution, immediately heat up to 178°C, keep stirring for 30 minutes, and control the pressure of the reaction system It is 2.5MPa; After the reaction is finished, it is cooled to 100° C., and the pressure is released to normal pressure, and carbon dioxide and ammonia in the reaction system are removed to ...

Embodiment 3

[0041] A method for preparing methionine, the specific steps are as follows:

[0042] (1) Add 1mol 3-methylthiopropionaldehyde, sodium cyanide, carbon dioxide, ammonia and 800 grams of water in the autoclave, and the molar ratio of 3-methylthiopropionaldehyde, sodium cyanide, carbon dioxide and ammonia is 1:1.05:2:4; then raise the temperature to 80°C, keep stirring for 10 minutes, then immediately raise the temperature to 120°C, keep stirring for 20 minutes, control the pressure of the reaction system to 2MPa, after the reaction is completed, release the pressure to normal pressure, and put the reaction system Unreacted carbon dioxide and ammonia are discharged to obtain hydantoin aqueous solution;

[0043] (2) The hydantoin aqueous solution that step (1) obtains is all added in the autoclave, and the mass fraction that adds 1.4mol is the sodium hydroxide aqueous solution of 40%, be warming up to 175 ℃ immediately, insulated and stirred for 30 minutes, control the reaction sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com