Dressing technology for recycling ultra-low-level gold ore

A process, extremely low technology, applied in the field of beneficiation process of oxidized gold ore, can solve the problem of high beneficiation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

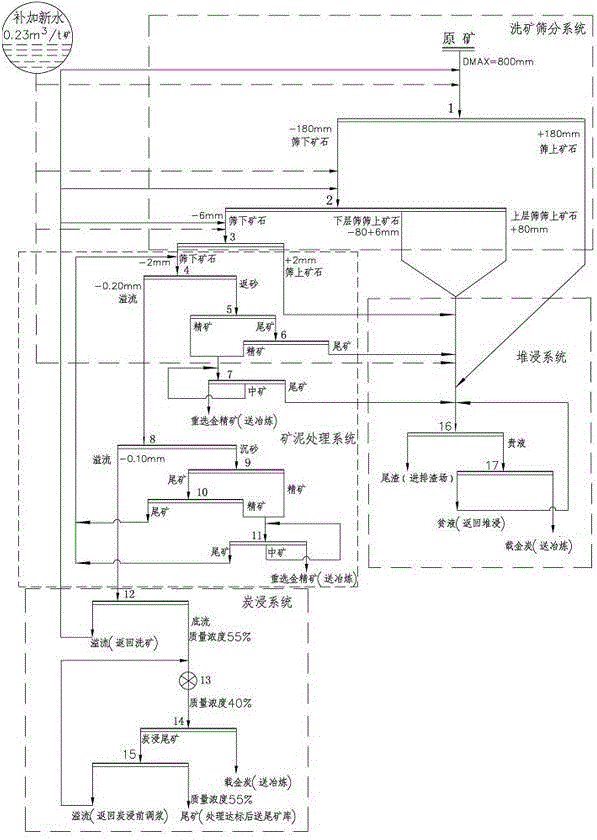

[0024] The beneficiation process of the present invention that can effectively recover extremely low-grade gold ore is composed of an ore washing and screening system, a slime treatment system, a carbon leaching system and a heap leaching system. The specific implementation process is as follows:

[0025] Ore washing and screening system: The raw ore with a maximum size of 800mm from the stope is directly sent to the bar sieve (1) for ore washing and screening without being crushed, and the ore under the bar sieve (1) is less than 180mm into the double The first-layer vibrating screen (2) washes the ore again, and the ore less than 6mm under the double-layer vibrating screen (2) is sent to the high-frequency fine screen (3) for further washing and screening;

[0026] Ore slime treatment system: The ore less than 2mm under the high-frequency fine screen (3) enters the spiral classifier (4) for classification; the sand returned from the spiral classifier (4) enters the first stag...

Embodiment 2

[0031]The beneficiation process of the present invention, which can effectively recover extremely low-grade gold ore, is implemented as follows: in addition to roughing and sweeping spiral concentrators (5), (6) and roughing and sweeping spiral chutes (9), ( 10) Except for roughing and sweeping Nelson concentrators (5), (6) and roughing and sweeping Nelson concentrators (9), (10), everything else is the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com