Iodometry process of measuring gold content in high accuracy and precision

A precision and accuracy technology, applied in the field of determination of gold, can solve the problems of high cost, low work efficiency, lengthy operation, etc., and achieve the effect of short operation time, high work efficiency and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This implementation example illustrates the method of the present invention to the assay result of low content gold in complex sample

[0049] Weigh an appropriate amount of sample according to the gold content of the sample in a porcelain evaporating dish, start from low temperature, bake in a high-temperature furnace at 550-650°C for 1-2 hours, stir 2-3 times in the middle, transfer it to a 300mL conical flask after cooling, add 30-50mL of aqua regia, heat and dissolve on a hot plate, steam to about 20mL (if it contains antimony and tungsten, add 1-2g of tartaric acid; if it contains acid-soluble silicate, add 5-10g of sodium fluoride, and boil), Cool to room temperature, dilute to 100mL with water, add 4 saturated bromine water, shake well, add 0.1 g of foamed plastic (wetted with water in advance), plug the bottle with a rubber stopper, and vibrate on a reciprocating shaker for 30-60 minutes.

[0050] Take out the gold-loaded foam plastic, wash it thoroughly with ta...

Embodiment 2

[0057] This implementation example illustrates the method of the present invention to the determination result of gold in the complex sample of medium content

[0058] Adopt national standard substance GBW07205, carry out by the operating condition of embodiment one, its measurement result is shown in Table 2

[0059] sample name

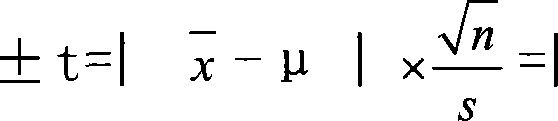

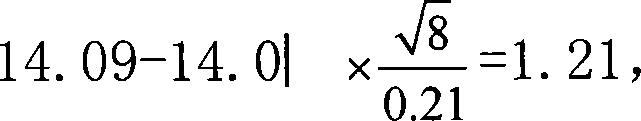

[0060] The significant difference (95% confidence level) of the method of the present invention is: ± t = | x ‾ - μ | × n s | 14.09 - 14.0 | × 8 0.21 = 1.21 , while t 95%,7 =2.36, 1.21-1 The allowable difference between laboratories for gold in ore is 1.80g·t -1 , It can be seen that the method of the present invention is satisfactor...

Embodiment 3

[0062] This implementation example illustrates the accuracy and precision of the method of the present invention for the determination of higher content gold samples

[0063] Adopt copper concentrate as test object, carry out by the operating condition of embodiment one, its measurement result is shown in Table 3

[0064] sample name

fire assay results

/ g·t -1

This method

Determination result / g·t -1

/ %

copper concentrate

199.98 (four

average result)

203.42,

198.95,

201.71,

202.55,

200.87,

199.10, average

Value: 201.10

0.90

[0065] The significant difference (95% confidence level) in this experiment is:

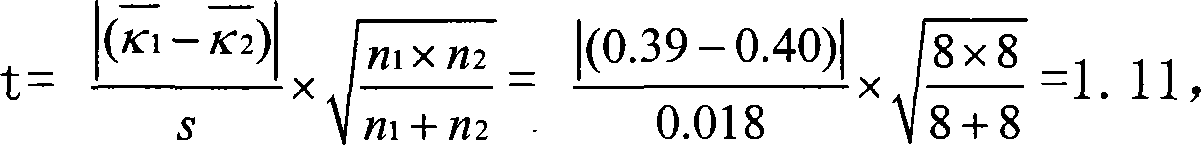

[0066] t = | ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com