Solderless automatic welding machine of golden bracelets and welding method

An automatic welding machine and no solder technology, which is applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems that the hollow bottom cover bracelet cannot reach the purity, the skills of the manufacturing workers are uneven, and the technical proficiency requirements are high, so as to achieve the realization of the product The effects of standardization, reduction of human resource costs, and less material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

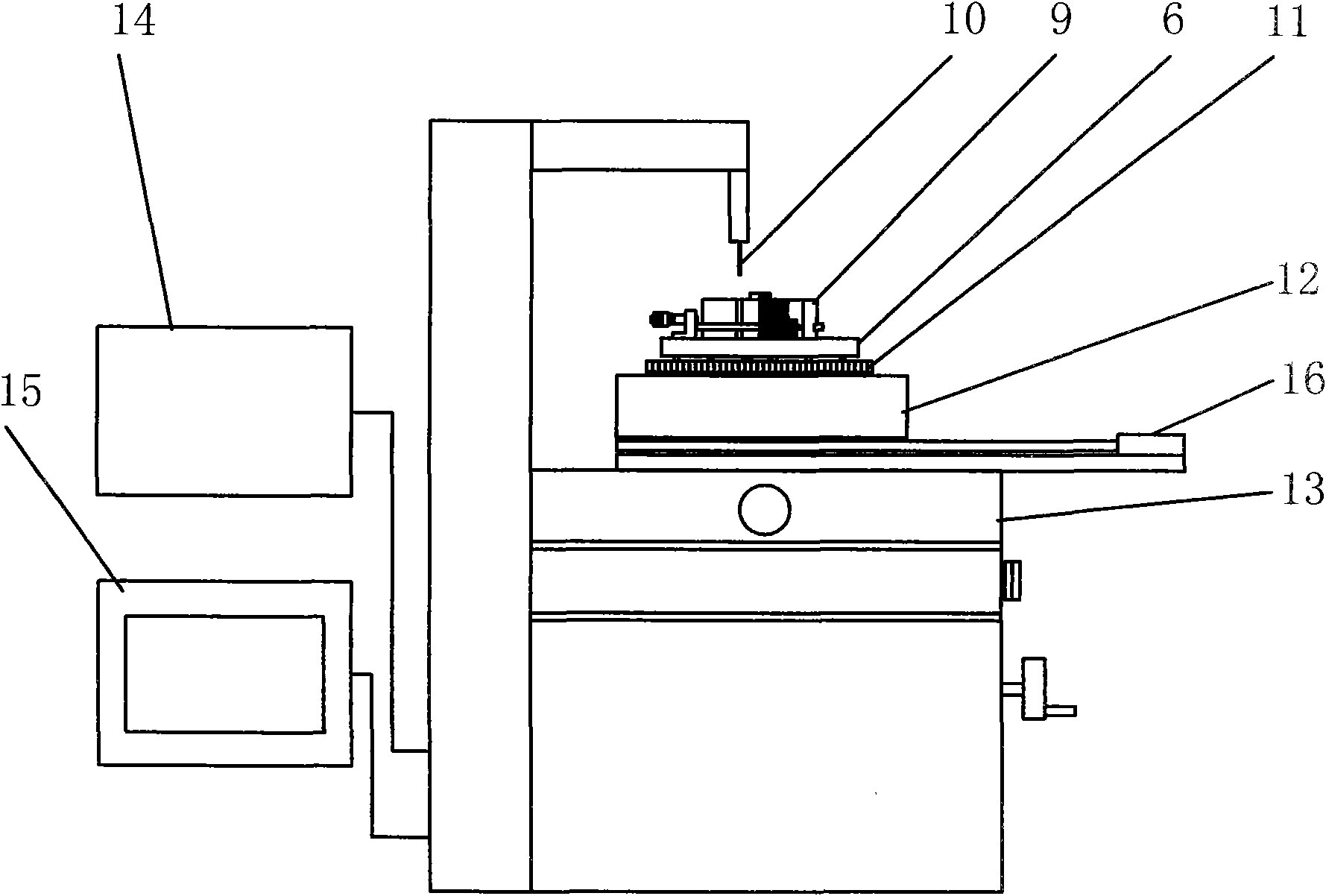

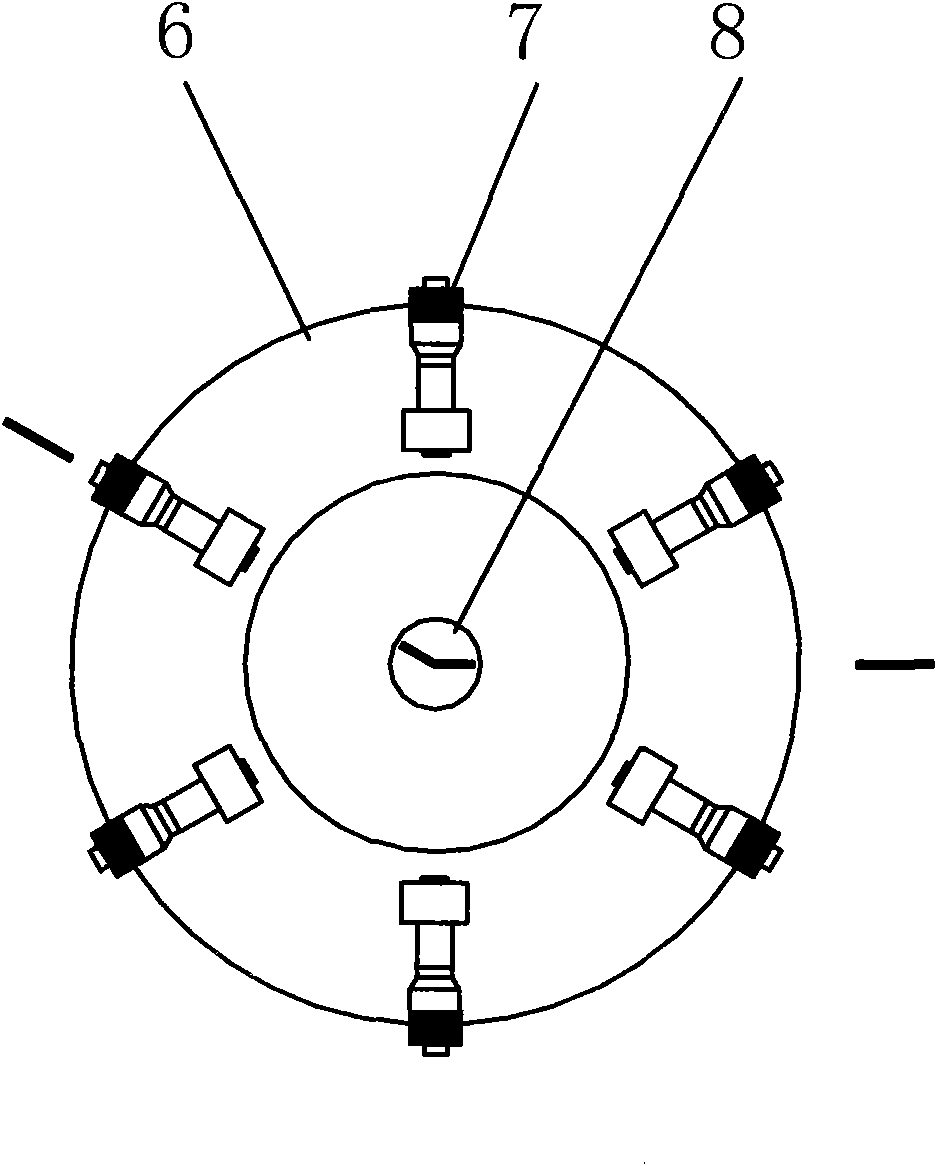

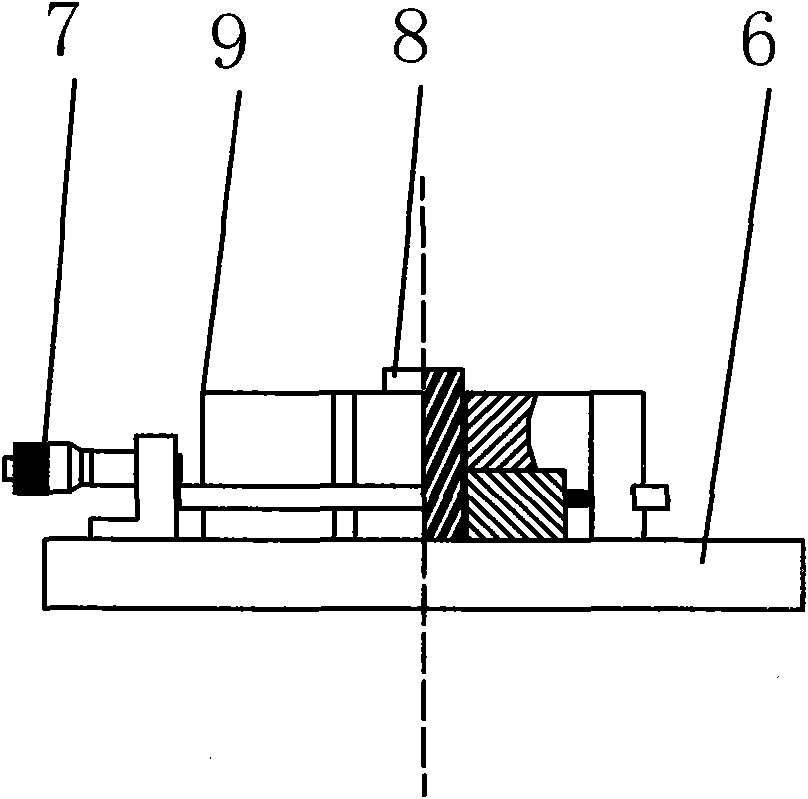

[0023] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 The solderless automatic welding machine for gold bracelets shown in , includes a movable clamping set for clamping the gold bracelet workpiece to be processed, and a movable clamping set for controlling and driving the movable clamping set for two-dimensional or three-dimensional movement. Electric platform control machine 15, and a welder three parts for outputting and controlling spot welding high-voltage pulse; Described movable clamping package includes electric translation table 13, electric rotary table 12, rotary pallet 6 and fixture 9, The electric translation table 13 is used as a base, and an electric rotary table 12 is arranged on it, and a clamp 9 is embedded on the rotating tray 6 at the upper end of the electric rotary table 12; the welding head 10 is arranged above the clamp 9 by a cantilever, and the output The end is connected to the welding head 10....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com