Catalyst for synthesizing vinylacetate and preparation method thereof

A vinyl acetate and catalyst technology, applied in the field of catalyst and its preparation, can solve the problem of inability to control the thickness of the active layer, and achieve the effects of improving the reaction activity and selectivity, improving the utilization rate, and reducing the secondary oxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Take 1.1 liter of spherical silica carrier (particle size 4-6 mm), soak it with 450 ml of aqueous solution containing 27.5 g of sodium silicate nonahydrate for 1 hour, and dry it at 60°C.

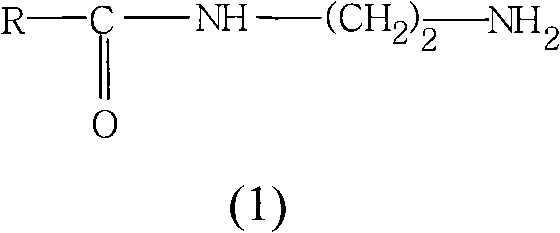

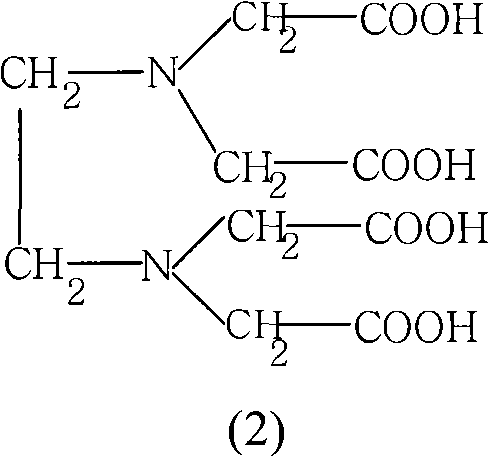

[0048] with 2.99 g of PdCl 2 and 1.82 g AuCl 3 Add 9 g of ethylenediaminetetraacetic acid disodium salt (EDTA disodium salt) or chelating agent A to 450 ml of the mixed solution, heat the mixed solution to 40-60°C under stirring, impregnate the above-mentioned alkaline carrier with this solution, and evenly Shake to avoid lumps, then let sit for 24 hours.

[0049] The catalyst precursor was impregnated with 30 ml of hydrazine hydrate with a concentration of 85 wt % for reduction, and the impregnation and reduction time was 5 hours.

[0050] The catalyst precursor was washed with deionized water until the effluent did not contain chloride ions (tested with silver nitrate), and then dried at 60°C.

[0051] The catalyst precursor was impregnated with 450ml aqueous solution containing...

Embodiment 2

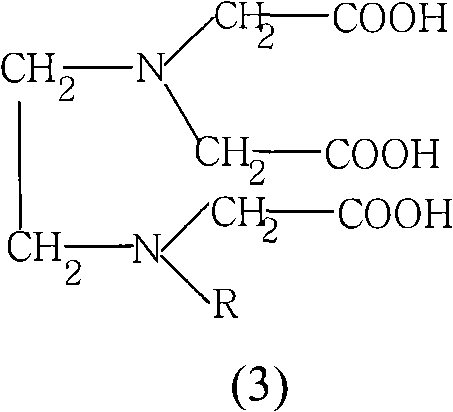

[0054] Adopt chelating agent B to replace chelating agent A, all the other are with embodiment 1.

Embodiment 3

[0056] Adopt chelating agent C to replace chelating agent A, all the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com