Method for comprehensively efficiently processing lead anode slime by using top-blown converter

A technology of lead anode slime and top-blown furnace, applied in the direction of improving process efficiency, etc., can solve the problems of low gold and silver enrichment, low metal recovery rate, and non-continuous completion, so as to increase production income and low process slag production rate , Good restoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

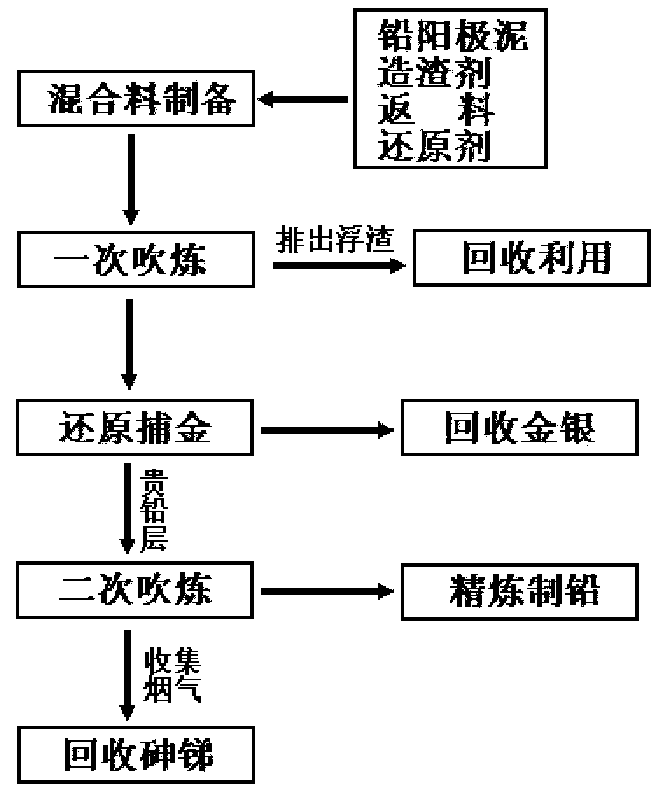

Method used

Image

Examples

Embodiment 1

[0040] A. Na 2 CO 3 The slagging agent soda ash with a content of 98.5%, the return material, the reducing agent coke and lead anode slime are mixed uniformly in a weight ratio of 100:5:25:5 to obtain a mixed material; The speed of h is continuously added to the top-blowing furnace, and the oxygen-enriched air and natural gas are sprayed into the top-blowing furnace molten pool through the top lance of the top-blowing furnace to react with the mixed materials. The amount of oxygen-enriched air and natural gas added is 12500Nm 3 / h, where the amount of natural gas added is 300Nm 3 / h, control the temperature in the top-blowing furnace to 1050°C, when the thickness of the slag layer reaches 0.5-1.0m, it will be released intermittently from the slag outlet of the top-blowing furnace, and flow into the mold through the chute to cast ingots; the lead anode slime Elements such as lead, arsenic, and antimony are reduced and gold and silver are captured and then sink to form a noble ...

Embodiment 2

[0043] A. GaF 2 The fluorite with a content of 97%, the return material, the reducing agent pulverized coal and the lead anode slime are mixed uniformly in a weight ratio of 100:8:20:6 to obtain a mixed material;

[0044] B, the mixed material in the step A is continuously added in the top-blowing furnace with a speed of 15t / h from the feed port of the top-blowing furnace, and oxygen-enriched air and diesel oil are sprayed into the top-blowing furnace molten pool by the special lance of the top-blowing furnace, The amount of oxygen-enriched air added is 12000Nm 3 / h, the amount of diesel oil added is 400L / h, and the temperature in the top-blowing furnace is controlled at 1100°C. When the thickness of the slag layer reaches 0.5-1.0m, it is released intermittently from the slag outlet of the top-blowing furnace and flows into the mold through the chute Internal ingot casting; elements such as lead, arsenic, and antimony in the lead anode slime are reduced and gold and silver ar...

Embodiment 3

[0047] A. Na 2 CO 3 The slagging agent soda ash with a content of 98.8%, the return material, the reducing agent anthracite and the lead anode slime are mixed uniformly in a weight ratio of 100:1:50:1 to obtain a mixed material; The speed is continuously added to the top-blowing furnace, and the oxygen-enriched air and gas are sprayed into the top-blowing furnace molten pool through the top lance of the top-blowing furnace to react with the mixed materials. The amount of oxygen-enriched air and gas added is 10800Nm 3 / h, where the amount of natural gas added is 259Nm 3 / h, control the temperature inside the top-blowing furnace to 900°C, and when the thickness of the slag layer reaches 0.5-1.0m, it will be discharged intermittently from the slag outlet of the top-blowing furnace, and flow into the mold through the chute to cast ingots; the lead anode slime Elements such as lead, arsenic, and antimony are reduced and gold and silver are captured and then sink to form a noble l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com