Flotation method for comprehensively recovering copper gold from copper separation tailings

A technology of tailings and copper selection, which is applied in flotation, solid separation, etc., can solve the problems of low copper grade and recovery rate in concentrate, weathering and oxidation of sulfide minerals, waste of copper selection tailings resources, etc., and achieve an increase in gold recovery rate , improve surface properties, and be easy for industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

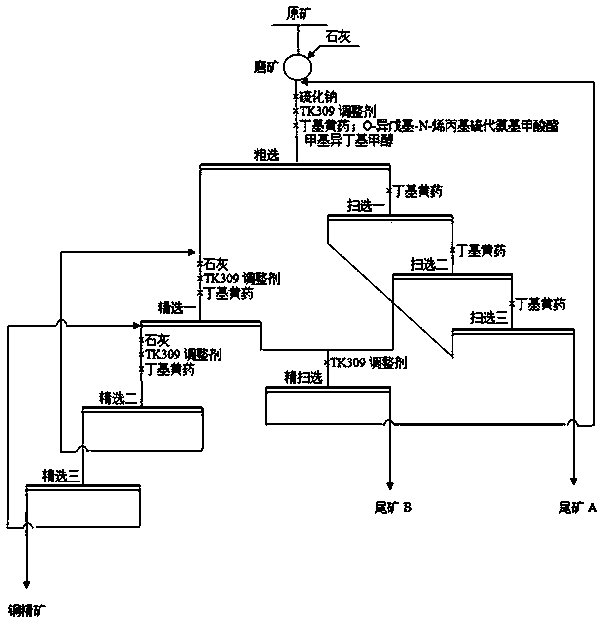

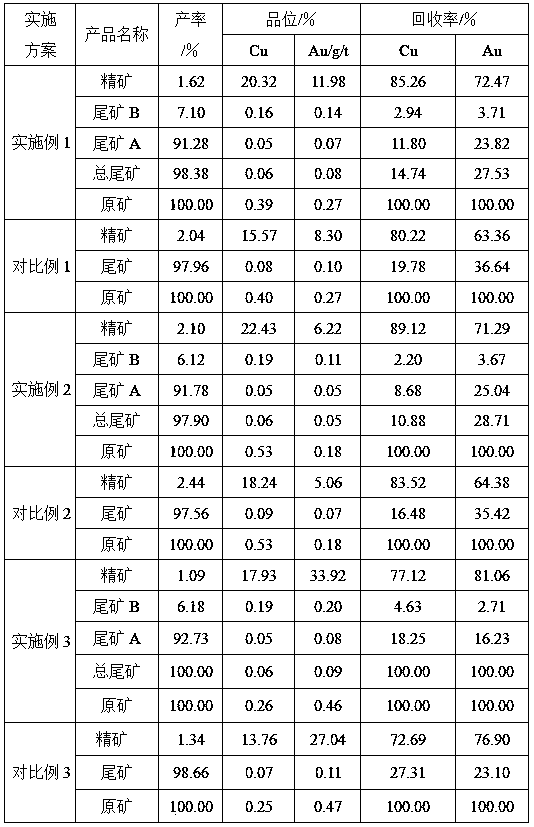

[0027] In this embodiment, the flotation method for comprehensive recovery of copper and gold from the copper tailings is adopted. figure 1 The technological process in the process selects a certain copper tailings, the grade of the copper tailings is 0.39% copper, 28% copper oxidation rate; 0.27 g / t gold, 3.05% sulfur, 12.35% iron, of which hematite The content of iron in ore and limonite is 5.07%, the content of magnesium oxide in gangue minerals is 15.32%, and the content of calcium oxide in gangue minerals is 11.86%. The specific implementation steps are as follows:

[0028] (1) Grind the copper beneficiation tailings until the ore particles with a particle size of less than 0.074mm account for 85% of the total weight of the copper beneficiation tailings. After grinding, add water to adjust the slurry to a mass percentage concentration of 28%. Add lime when grinding 3Kg / t;

[0029] (2) Add 200 g / t of sodium sulfide and 1600 g / t of TK309 combination regulator to the pulp ...

Embodiment 2

[0049] In this embodiment, the flotation method for comprehensive recovery of copper and gold from the copper tailings is adopted. figure 1 The technological process in the selection of copper tailings, the grade of copper tailings in weight percentage is 0.53% copper, copper oxidation rate 37%; gold 0.18 g / t, sulfur 3.26%, iron 10.79%, of which hematite The content of iron in ore and limonite is 4.87%, the content of magnesium oxide in gangue minerals is 11.48%, and the content of calcium oxide in gangue minerals is 9.50%. The specific implementation steps are as follows:

[0050] (1) Grind the copper beneficiation tailings until the ore particles with a particle size of less than 0.074mm account for 80% of the total weight of the copper beneficiation tailings. After grinding, add water to adjust the slurry to a mass percentage concentration of 30%. Add lime when grinding 2Kg / t;

[0051] (2) Add 100 g / t of sodium sulfide and 1000 g / t of TK309 combination regulator to the pu...

Embodiment 3

[0071] In this embodiment, the flotation method for comprehensive recovery of copper and gold from the copper tailings is adopted. figure 1 The technological process in the selection of copper tailings, the grade of copper tailings is 0.25% copper; copper oxidation rate 18%; gold 0.47g / t, sulfur 2.94%, iron 13.65%, of which hematite The content of iron in ore and limonite is 5.98%, the content of magnesium oxide in gangue minerals is 15.43%, and the content of calcium oxide in gangue minerals is 12.30%. The specific implementation steps are as follows:

[0072] (1) Grind the copper beneficiation tailings until the ore particles with a particle size of less than 0.074mm account for 95% of the total weight of the copper beneficiation tailings. After grinding, add water to adjust the slurry to a mass percentage concentration of 25%. Add lime when grinding 4.5Kg / t;

[0073] (2) Add 300 g / t of sodium sulfide and 1700 g / t of TK309 combination regulator to the pulp ground in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com