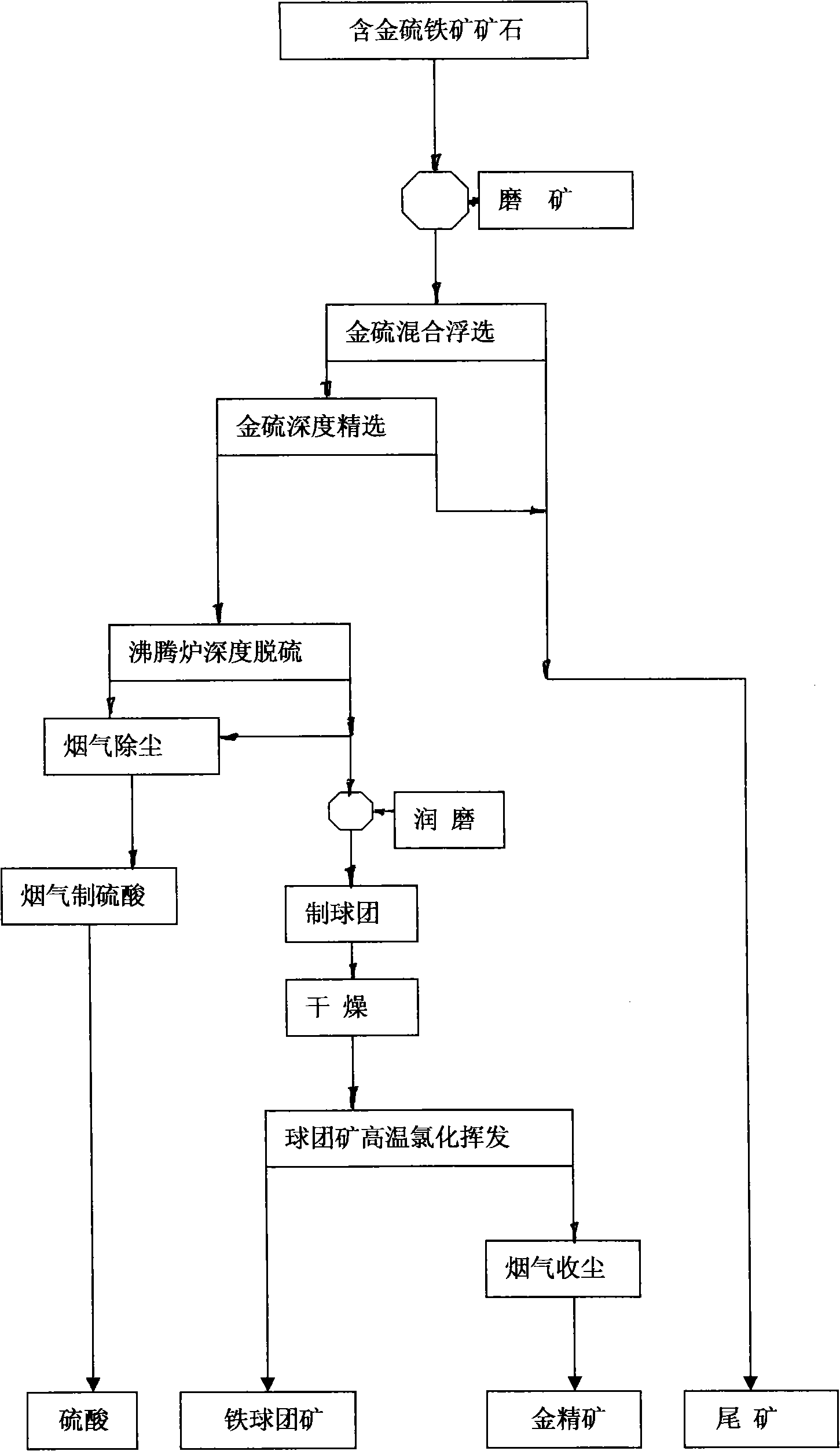

Method for comprehensively recovering gold, iron and sulphur resource from gold-containing sulfurous iron ore

A technology for recovery of pyrite and gold, applied in chemical instruments and methods, wet separation, flotation, etc., can solve the problems of difficult cyanide leaching of pyrite, difficulty in effective recovery, poor recovery of gold, etc. , to achieve the effects of high difficulty in ore dressing, high recovery rate, and guaranteed gold recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 An example of comprehensive utilization of pyrite resources with a gold content of 0.2-1 g / t and a sulfur mass percentage of 5%-10%.

[0054] 1. Production of gold-bearing high-grade sulfur concentrate:

[0055] The mass percentage of sulfur is 5% to 10%, the gold content is 0.2 to 1g / t, and the gold-bearing pyrite ore that is difficult to cyanide leaching, after grinding, the fineness reaches the weight percentage of the particle size of less than 0.074mm 50% to 95%, the monomer dissociation degree of gold mineral and pyrite combination and gangue mineral is greater than 95%. Add 500g / ton~1500g / ton sulfuric acid as activator, add xanthate 150g / ton~300g / ton as flotation collector, add foaming agent 50g / ton~100g / ton for gold sulfur Mixed flotation to obtain gold-sulfur mixed concentrate. The gold-sulfur mixed concentrate is beneficiated four to five times to obtain a gold-bearing high-grade sulfur concentrate with a total mass percentage of sulfide minerals g...

Embodiment 2

[0062] Embodiment 2: An embodiment of comprehensive utilization of gold-bearing pyrite resources with a mass percentage of sulfur of 10% to 30% and a gold content of 1 to 3 g / t.

[0063] 1. Production of gold-bearing high-grade sulfur concentrate:

[0064] The mass percentage of sulfur is 10% to 30%, the gold content is 1 to 3g / t, and the gold-bearing pyrite ore that is difficult to cyanide leaching, after the ore grinding, the fineness reaches the weight percentage of the particle size of less than 0.074mm 50% to 95%, the monomer dissociation degree of gold mineral and pyrite combination and gangue mineral is greater than 95%. Add 1500g / ton~3000g / ton sulfuric acid as activator, add xanthate 300g / ton~600g / ton as flotation collector, add foaming agent 30g / ton~50g / ton for gold sulfur Mixed flotation to obtain gold-sulfur mixed concentrate. The gold-sulfur mixed concentrate is beneficiated three to four times to obtain a gold-bearing high-grade sulfur concentrate with a total m...

Embodiment 3

[0071] Embodiment 3: An embodiment of comprehensive resource utilization of gold-bearing pyrite with a sulfur mass percentage of 30% to 38% and a gold content of 2 to 6 g / t.

[0072] 1. Production of gold-bearing high-grade sulfur concentrate:

[0073] The mass percentage of sulfur is 30%-38%, the gold content is 2-6g / t, and the gold-bearing pyrite ore that is difficult to cyanide leaching, after the ore grinding, the fineness reaches the weight percentage of the particle size of less than 0.074mm 50% to 95%, the monomer dissociation degree of gold mineral and pyrite combination and gangue mineral is greater than 95%. Add 2500g / ton-5000g / ton sulfuric acid as activator, add xanthate 500g / ton-800g / ton as flotation collector, add foaming agent 10g / ton-40g / ton for gold sulfur Mixed flotation to obtain gold-sulfur mixed concentrate. The gold-sulfur mixed concentrate is subjected to two to three times of beneficiation to obtain a gold-bearing high-grade sulfur concentrate with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com