Refinement technology of high-purity gold

A process, pure gold technology, applied in the direction of improving process efficiency, can solve problems such as pollution and equipment corrosion environment, and achieve the effects of wide adaptability of raw materials, high recovery rate of gold and silver, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

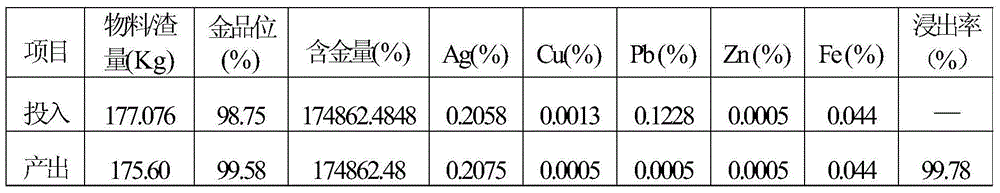

[0038] 1. Production of raw materials and pharmaceuticals

[0039] The gold raw materials used in production are crude gold and gold mud from Zhaojin Group. The multi-element analysis of representative materials is now listed in Table 1. The chemicals used in the production process are all industrial products. The main chemicals used are listed in Table 2 below. Show.

[0040] Table 1 Multi-element analysis of gold ingot raw materials

[0041] Au(%)

Ag(%)

Cu(%)

Pb(%)

Zn(%)

Fe(%)

Pt(%)

Pd(%)

Ca(%)

Si(%)

98.75

0.2058

0.0013

0.1228

0.0005

0.0440

0.0005

0.0005

0.0029

0.0019

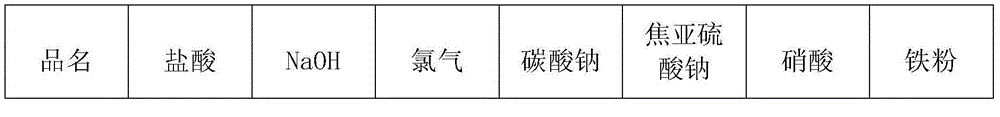

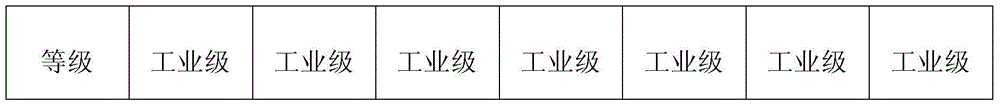

[0042] Table 2 Chemicals used in production

[0043]

[0044]

[0045] 2. Gold refining method

[0046] 1) Gold ingot pulverization: This process is completed by a hydraulic tilting intermediate frequency furnace and an imported high-pressure pulverization pump. The pulverization capacity is 30kg / batch, and...

Embodiment 2

[0064] 1. Production of raw materials and pharmaceuticals

[0065] The gold raw materials used in production are crude gold and gold mud from Zhaojin Group. The multi-element analysis of representative materials is now listed in Table 1. The chemicals used in the production process are all industrial products. The main chemicals used are listed in Table 7 below. Show.

[0066] Table 7 Multi-element analysis of gold ingot raw materials

[0067] Au(%)

Ag(%)

Cu(%)

Pb(%)

Zn(%)

Fe(%)

Pt(%)

Pd(%)

Ca(%)

Si(%)

99.50

0.2100

0.0101

0.014

0.0005

0.0005

0.0005

0.0005

0.0005

0.0052

[0068] 2. Gold refining method

[0069] 1) Gold ingot pulverization: This process is completed by a hydraulic tilting intermediate frequency furnace and an imported high-pressure pulverization pump. The pulverization capacity is 30kg / batch, and the time is 0.5h. mm accounted for more than 95%.

[0070] 2) Pre-soa...

Embodiment 3

[0086] 1. Production of raw materials and pharmaceuticals

[0087] The gold raw materials used in production are crude gold and gold mud from Zhaojin Group. The multi-element analysis of representative materials is now listed in Table 1. The chemicals used in the production process are all industrial products. The main chemicals used are listed in Table 12 below. Show.

[0088] Table 12 Multi-element analysis of crude gold raw materials and gold mud

[0089] Au(%)

Ag(%)

Cu(%)

Pb(%)

Zn(%)

Fe(%)

Pt(%)

Pd(%)

Ca(%)

Si(%)

90.05

4.550

0.1421

0.0232

0.0005

0.0229

0.0008

0.0005

0.0005

0.0012

[0090] 2. Gold refining method

[0091] 1) Gold ingot pulverization: This process is completed by a hydraulic tilting intermediate frequency furnace and an imported high-pressure pulverization pump. The pulverization capacity is 30kg / batch, and the time is 1.5h. mm accounted for more than 95%.

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com