Citric acid gold potassium for gilding and preparation method thereof

A technology of gold potassium citrate and potassium citrate, which is applied in the field of gold-plated potassium citrate and its preparation, and can solve problems such as seldom use, high toxicity, and excessive potassium cyanide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

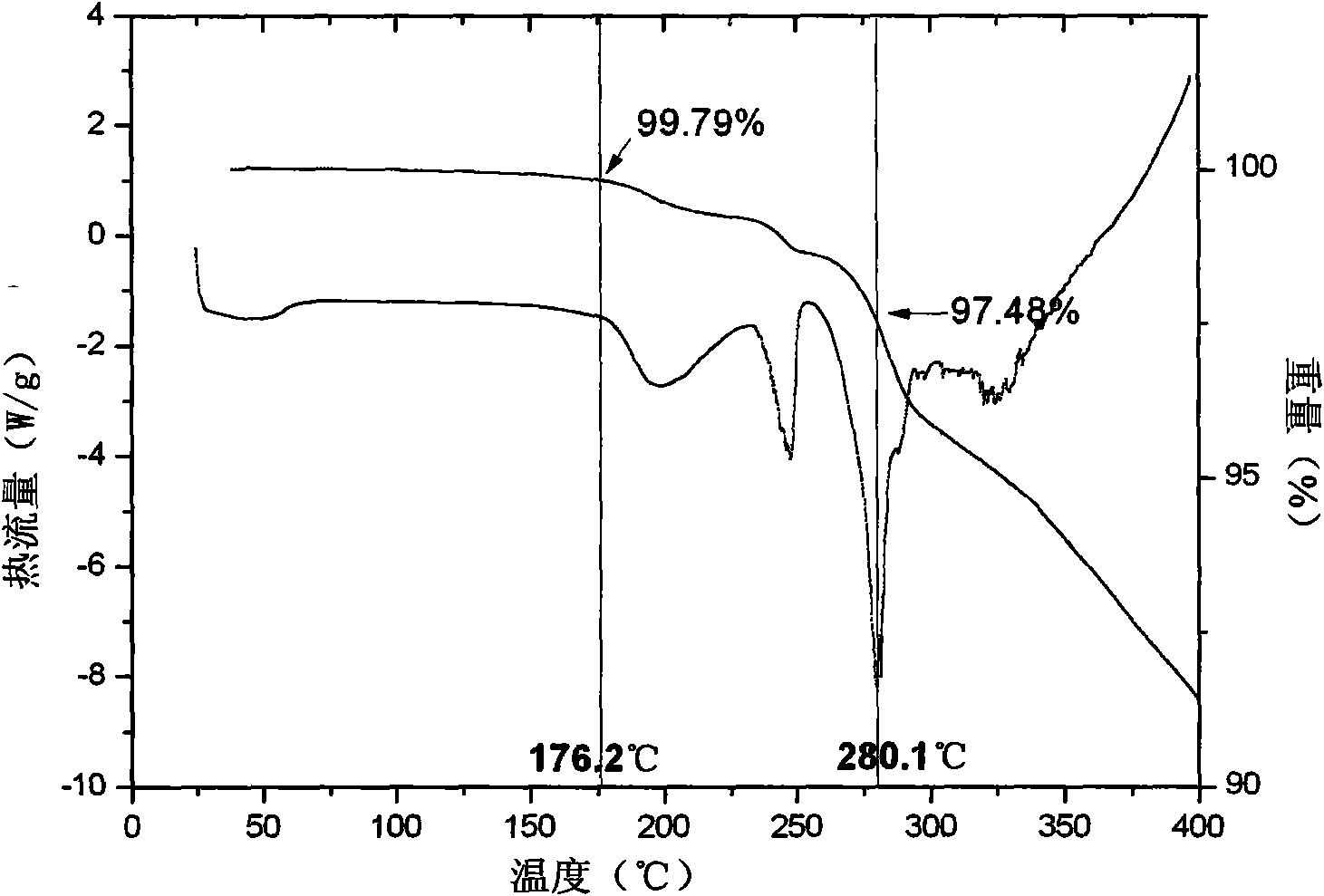

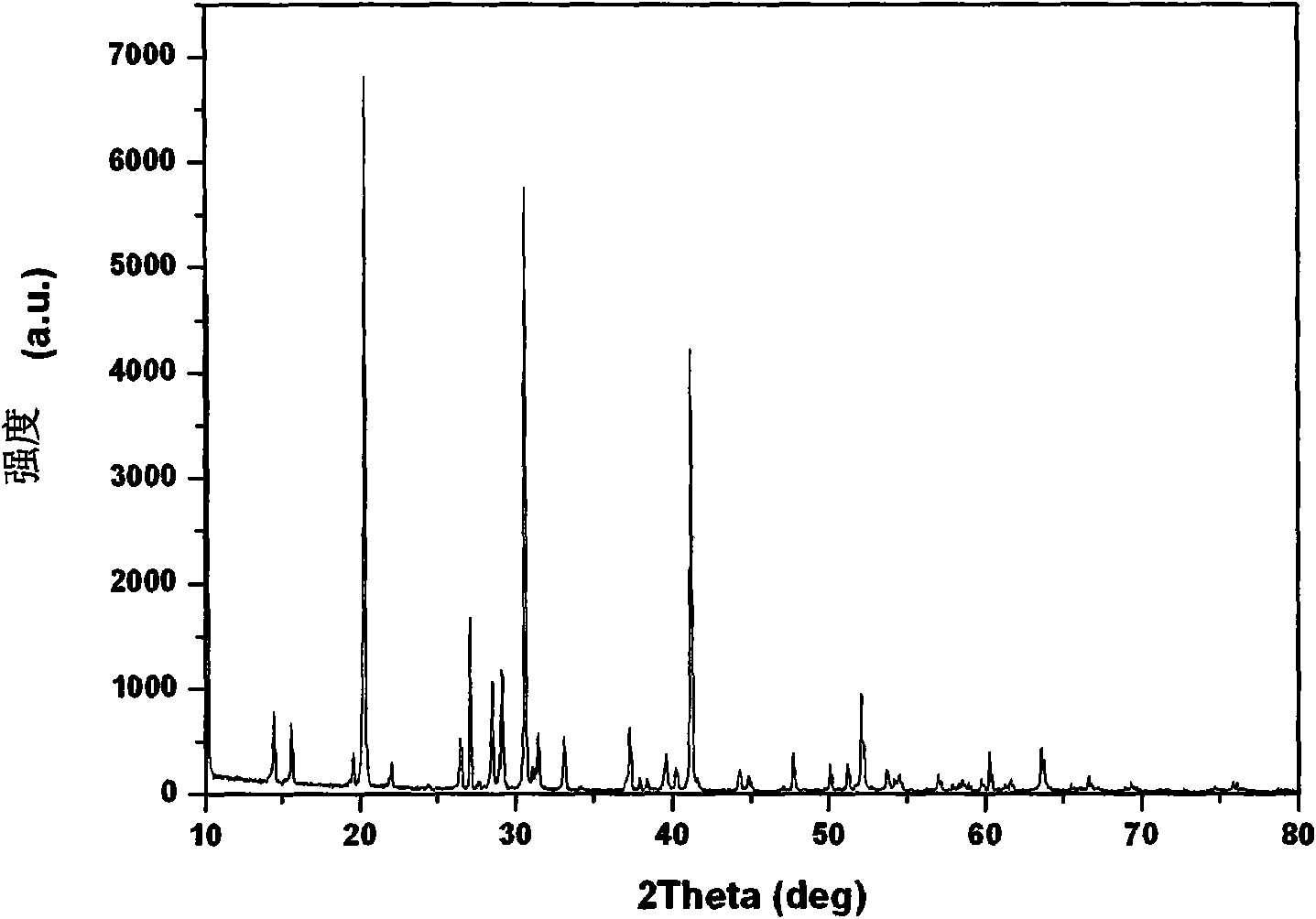

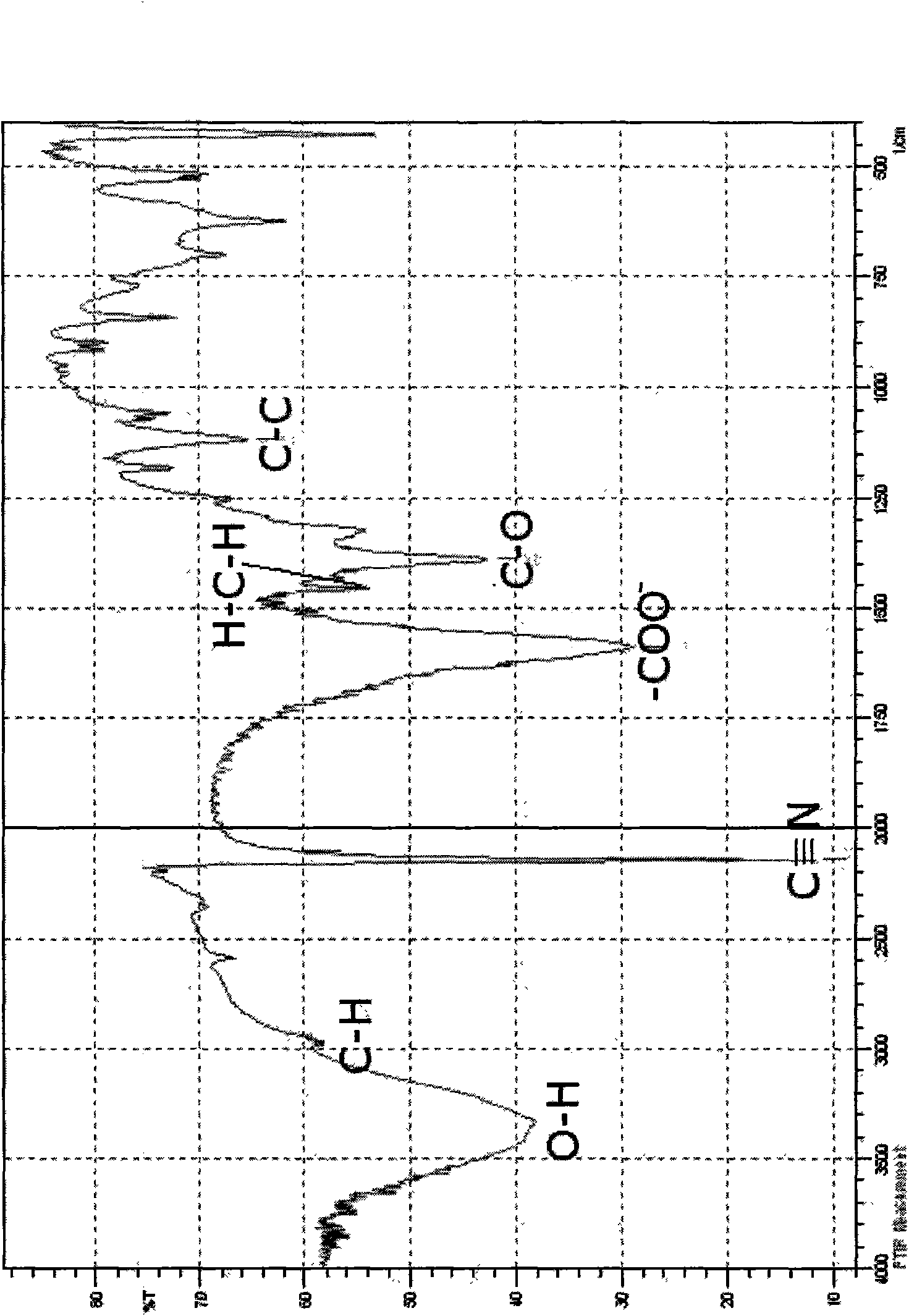

[0031] Example 1 : At normal temperature and pressure, add 10000mL water into the reactor, turn on the stirrer and the heating switch, and when the water temperature rises to 85°C, add 500g of gold trichloride under stirring conditions to make it dissolve completely; The above-mentioned gold trichloride solution is kept at a temperature of 85°C under stirring conditions, and concentrated for 4 hours. When the volume is 2000mL, add water to the reactor to 10000mL. Under the same conditions, when it is concentrated to 2000mL, add Water to 10,000mL; keep the above gold trichloride solution at 85°C, take 800g of potassium citrate, dissolve it in 20,000mL of 85°C hot water, filter to remove trace impurities in the solution, and add the prepared potassium citrate solution into the reactor During the process, measure the pH value while adding, and stop adding potassium citrate solution dropwise when the pH value is adjusted to 5; take 50g of ethylenediaminetetraacetic acid, dissolve...

Embodiment 2

[0032] Example 2 : At normal temperature and pressure, add 10000mL water into the reactor, turn on the stirrer and the heating switch, when the water temperature rises to 80°C, add 400g of gold trichloride under stirring conditions to make it dissolve completely; The above-mentioned gold trichloride solution is kept at a temperature of 80°C under stirring conditions, and concentrated for 10 hours. When the volume is 2000mL, add water to the reactor to 10000mL. Under the same conditions, when it is concentrated to 2000mL, add Water to 10000mL; keep the above gold trichloride solution at 80°C, take 1200g of potassium citrate, dissolve it in 20000mL of 80°C hot water, filter to remove trace impurities in the solution, and add the prepared potassium citrate solution into the reactor During the process, measure the pH value while adding, and stop adding potassium citrate solution dropwise when the pH value is adjusted to 7; take 60g of ethylenediaminetetraacetic acid, dissolve it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com