External appearance defect examination method for circuit board

A technology of appearance defects and inspection methods, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of difficult quality control of circuit boards, slow inspection speed, inadaptability, etc., and achieve flexibility and scalability Strong performance, fast inspection speed, and high inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings:

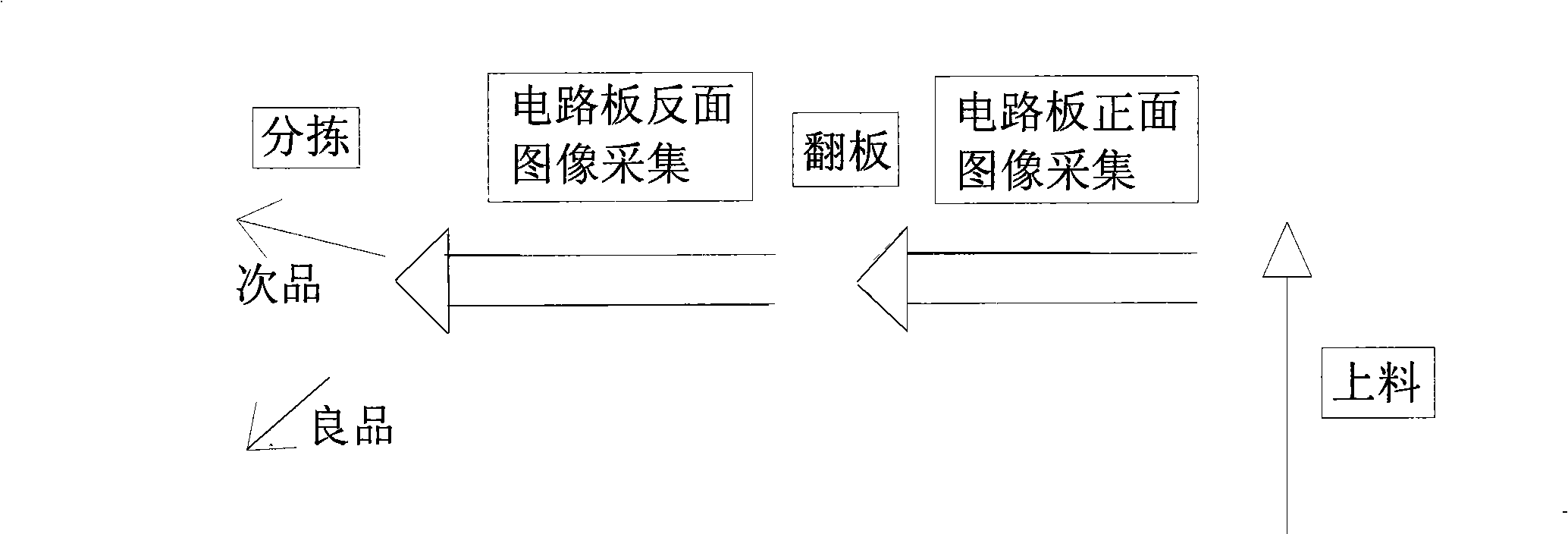

[0021] as attached figure 1 As shown, the method is used for automatic inspection of various defects in the appearance of the circuit board when automatic production is realized. The method includes:

[0022] Loading, image acquisition of the front side of the circuit board, flipping, image acquisition of the reverse side of the circuit board, image analysis, and sorting.

[0023] The loading can be done automatically, and the circuit boards to be inspected are placed on the conveyor belt one by one, and the conveyor belt carries the circuit boards and moves to the scanning device.

[0024] The scanning device is located above the conveyor belt. When the circuit board to be inspected passes through the scanning device, the scanning device scans the image of the front of the circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com