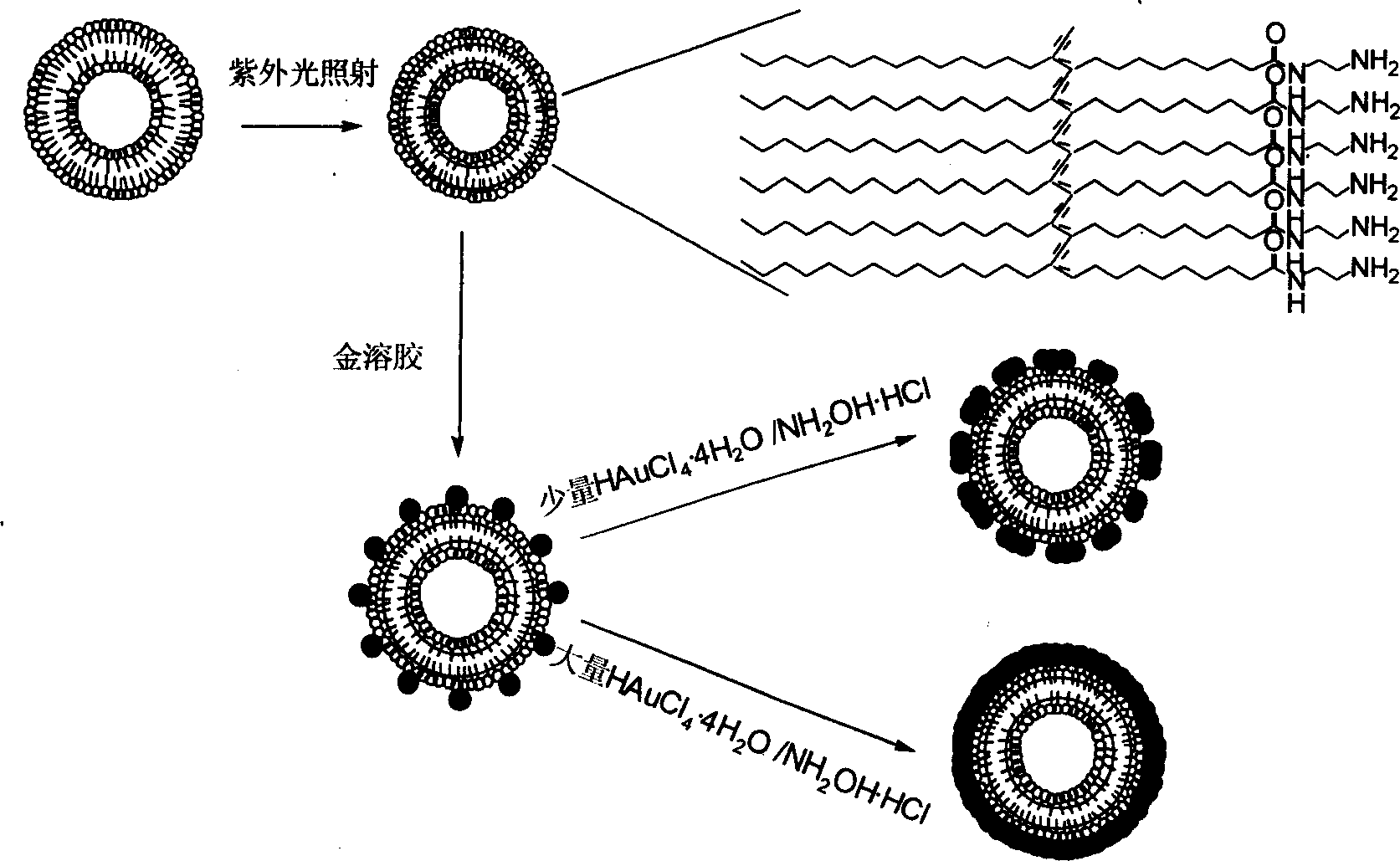

Process for preparing controllable hollow nanometer gold ball based on polymeric vesicle mold plates

A hollow nano, polymeric technology, which is applied in the preparation of microspheres, the method of granulating raw materials, and the preparation of microcapsules, can solve the problems of poor stability and high cost of non-polymeric vesicle templates, and achieve the surface coating rate. Good controllability, simple preparation and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

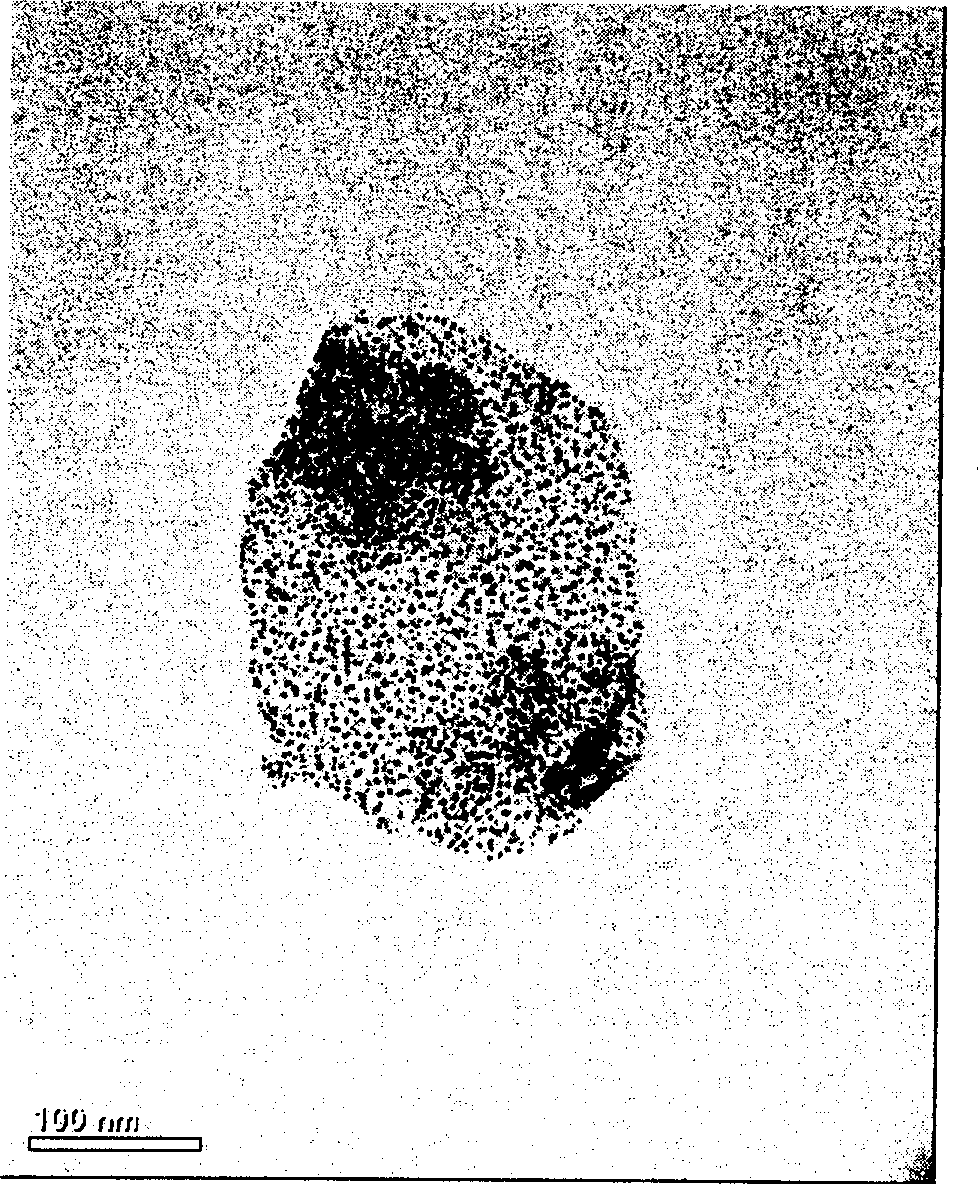

Examples

Embodiment 1

[0018] (1) Synthesis of lipid monomers: according to the literature "German Applied Chemistry" magazine, 2003, vol. 42, page 3264 (I.Gill et al., Angew.Chem.Int.Ed.2003, vol. 42, page 3264), 10 mL, 2.4 mM C 6 h 11 N=C=NC 6 h 11 A solution of dichloromethane was added to 10 mL of 2.45 mM 10,12-pentacosyldiynoic acid [CH 3 -(CH 2 ) n -C≡C-C≡C-(CH 2 ) l -COOH wherein l=8, n=11] in the dichloromethane solution, the mixed solution was placed in a dark room and stirred (300 rpm) at room temperature to react for 1 hour, and then the mixed solution was added dropwise in 20 minutes Add it to 10 mL, 4 mM ethylenediamine in dichloromethane solution and continue to stir (300 rpm) to react for 1 hour. The reacted solution was diluted with 20 mL of petroleum ether and filtered, the filtrate was evaporated to dryness with a rotary evaporator, and the dried product was purified with a silica gel column (Kieselgel 60, the solvent was chloroform-methanol with a volume ratio of 5:1) to o...

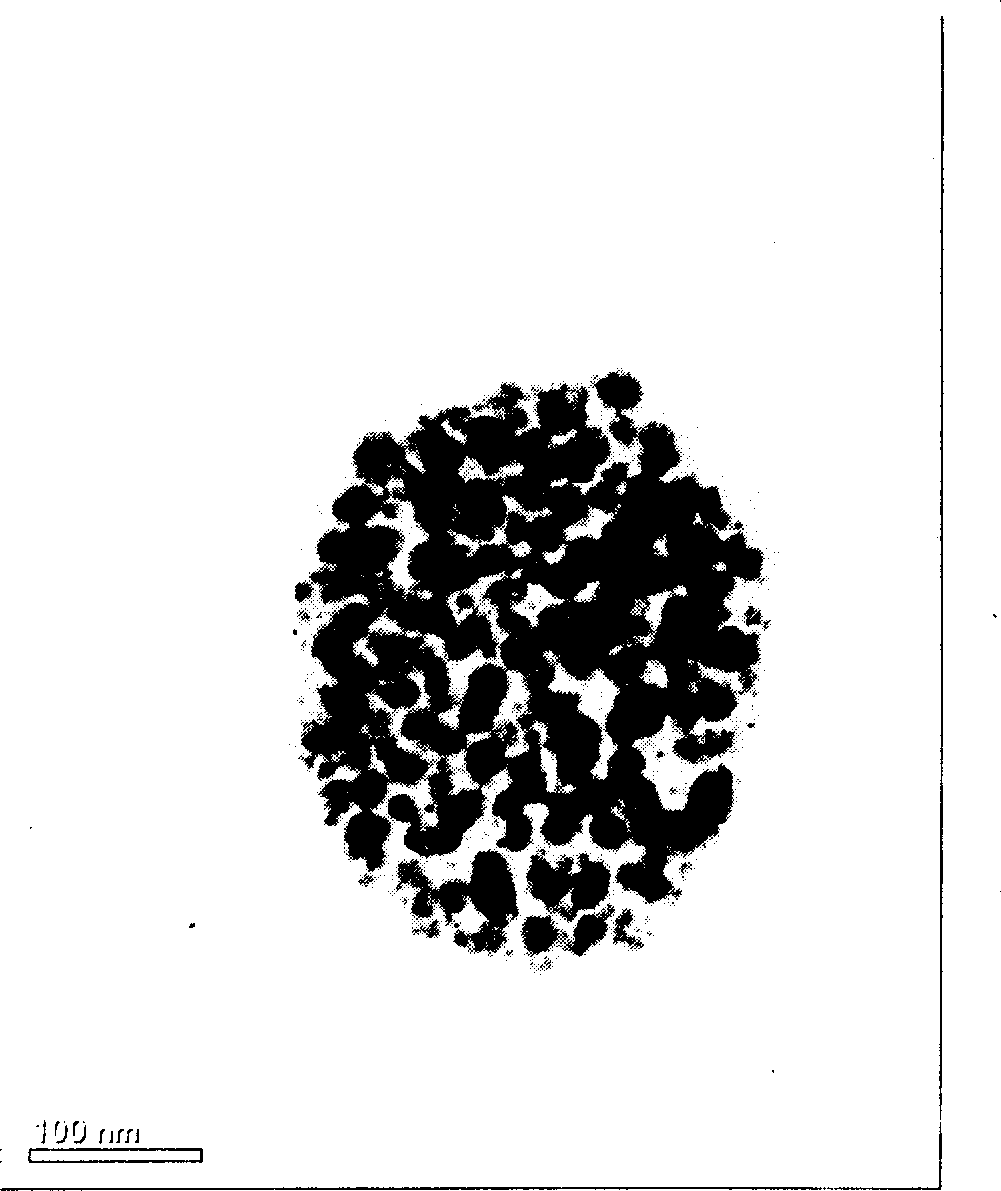

Embodiment 2

[0022] (1) Synthesis of lipid monomers: according to the literature "German Applied Chemistry" magazine, 2003, vol. 42, page 3264 (I.Gill et al., Angew.Chem.Int.Ed.2003, vol. 42, page 3264), 10 mL, 2.4 mM C 6 h 11 N=C=NC 6 h 11 A solution of dichloromethane was added to 10 mL of 2.45 mM 10,12-tricosyldiynoic acid [CH 3 -(CH 2 ) n -C≡C-C≡C-(CH 2 ) l -COOH wherein l=8, n=9] in dichloromethane solution, the mixed solution was placed in a dark room and stirred (300 rpm) at room temperature to react for 1 hour, then the mixed solution was added dropwise in 20 minutes Add it to 10 mL, 4 mM ethylenediamine in dichloromethane solution and continue to stir (300 rpm) to react for 1 hour. The reacted solution was diluted with 20 mL of petroleum ether and filtered, the filtrate was evaporated to dryness with a rotary evaporator, and the dried product was purified with a silica gel column (Kieselgel 60, the solvent was chloroform-methanol with a volume ratio of 5:1) to obtain Lipi...

Embodiment 3

[0026] (1) Synthesis of lipid monomers: according to the literature "German Applied Chemistry" magazine, 2003, vol. 42, page 3264 (I.Gill et al., Angew.Chem.Int.Ed.2003, vol. 42, page 3264), 10 mL, 2.4 mM C 6 h 11 N=C=NC 6 h 11 A solution of dichloromethane was added to 10 mL of 2.45 mM 2,4-tricosyldiynoic acid [CH 3 -(CH 2 ) n -C≡C-C≡C-(CH 2 ) l -COOH wherein l=0, n=17] in the dichloromethane solution, the mixed solution was placed in a dark room and stirred (300 rpm) at room temperature to react for 1 hour, then the mixed solution was added dropwise in 20 minutes Add to 10 mL, 4 mM dichloromethane solution of hexamethylenediamine and continue to stir (300 rpm) to react for 1 hour. The reacted solution was diluted with 20 mL of petroleum ether and filtered, the filtrate was evaporated to dryness with a rotary evaporator, and the dried product was purified with a silica gel column (Kieselgel 60, the solvent was chloroform-methanol with a volume ratio of 5:1) to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com