Manufacturing method of nail head gold bump

A bump and stud head technology is applied in the field of stud head gold bump preparation, which can solve the problems of chip breakage, increase bonding force and bonding time, high material cost, etc., and achieve the effect of preventing failure and improving coplanarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

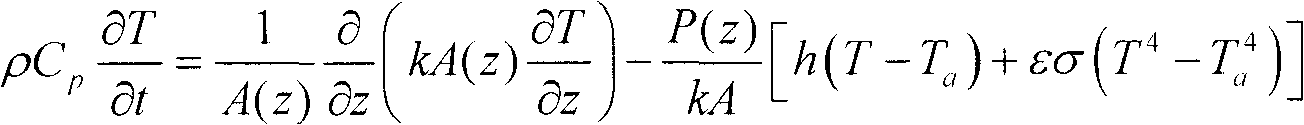

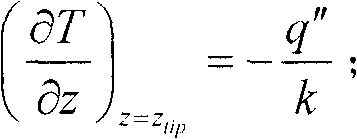

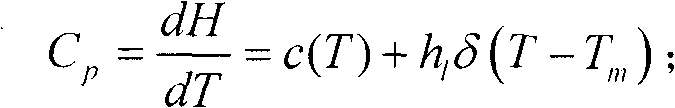

[0037] A method for preparing gold stud bumps with a gold ball size of 2 mils, comprising the following process: (1) through the image processing system, the rivet is accurately positioned above the pad, and the electronic discharge system is placed on the electronic spark rod A high voltage of 3kV is generated between the tail of the gold wire formed after the previous bonding cycle, and the formed arc generates high temperature to melt the bottom of the gold wire, and the first melted gold wire makes the liquid gold ball roll upwards under the action of surface tension Gold balls are formed, the discharge current is 30mA, and the discharge time is 0.8ms. The size of the gold balls depends on the energy when they are formed, and the energy depends on the temperature. The size of the gold balls determines the size of the gold bumps. Coplanarity, in order to improve the coplanarity of the gold bumps, the following equation is used to control the size of the gold balls:

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com