Castable polyurea compositions for golf ball covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

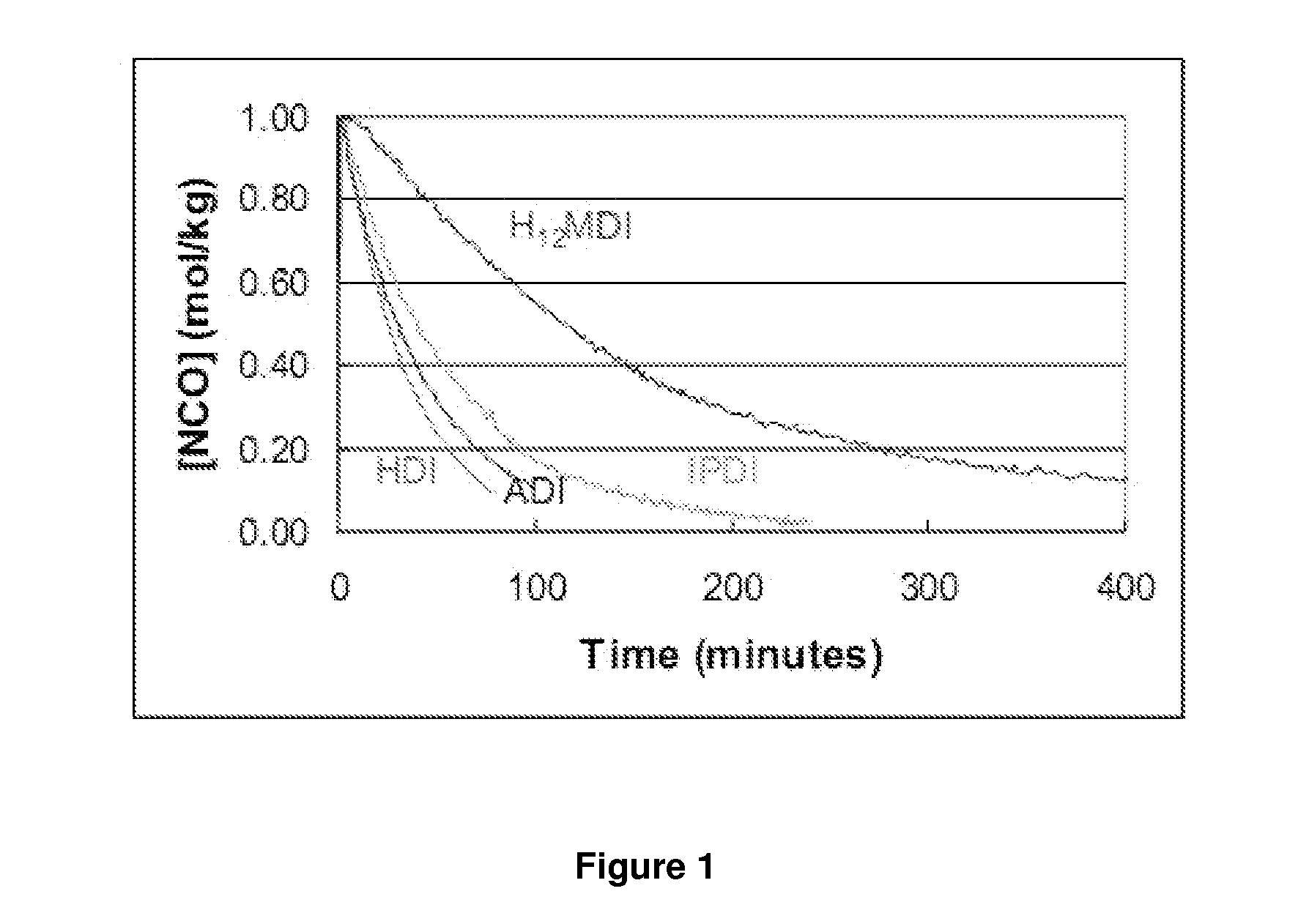

Image

Examples

example 5

Golf Ball Example 5

[0180]Following the procedure of in Golf Ball Example 2, 100 grams of Prepolymer Example 5 at 70° C. is mixed with 13.27 grams of Ethacure 100 LC at room temperature for 35 seconds. The resulting elastomer has 60% resilience and 45 Shore D hardness.

example 6

Golf Ball Example 6

[0181]Following the procedure of in Golf Ball Example 2, 100 grams of Prepolymer Example 6 at 70° C. is mixed with 13.53 grams of Ethacure 100 LC at room temperature for 25 seconds. The resulting elastomer has 59% resilience and 46 Shore D hardness.

example 7

Golf Ball Example 7

[0182]Following the procedure of in Golf Ball Example 2, 100 grams of Prepolymer Example 7 at 70° C. is mixed with 13.86 grams of Ethacure 100 LC at room temperature for 45 seconds. The resulting elastomer has 61% resilience and 48 Shore D hardness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com