Hydrogen sensor testing system

A test system and sensor technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of increasing the complexity of the circuit, and achieve the effect of high sealing and no gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

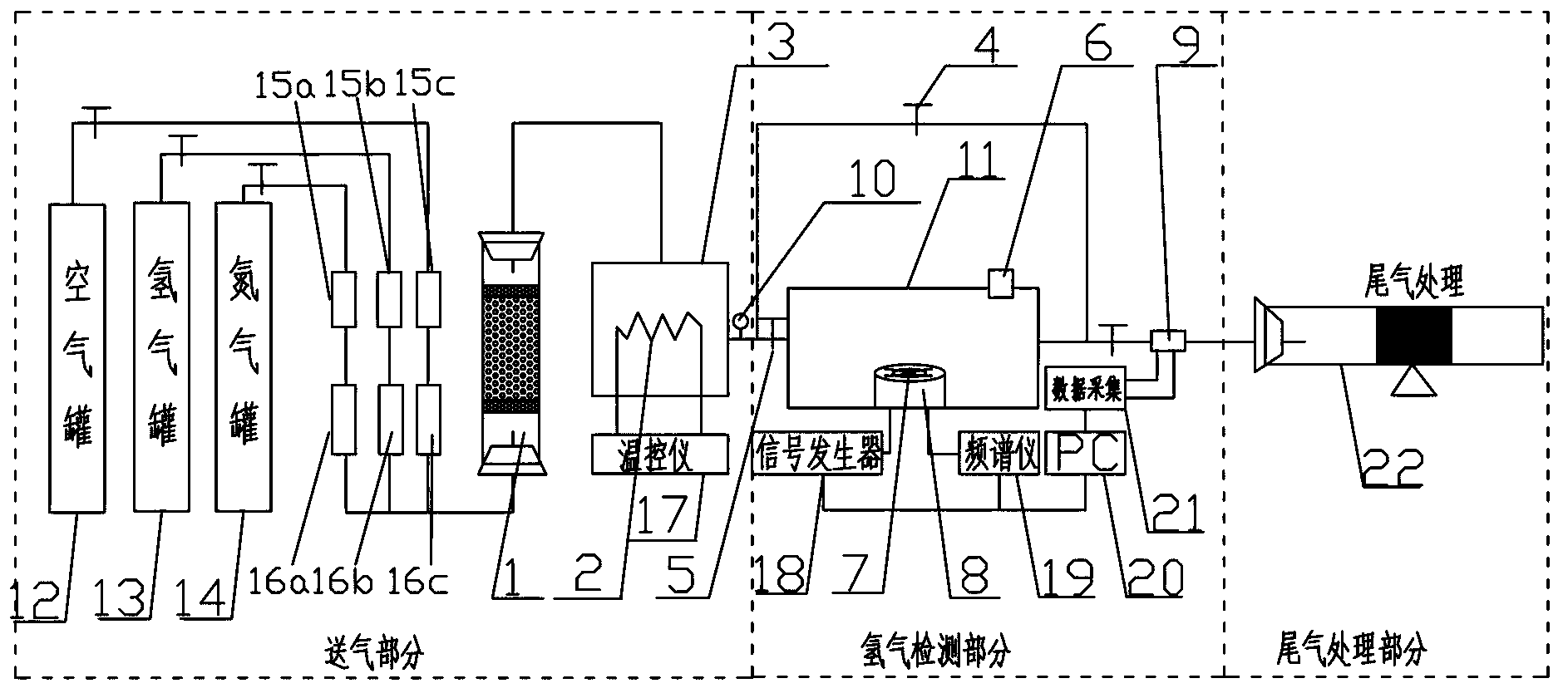

[0041] Such as figure 1 As shown, this embodiment discloses a hydrogen sensor testing system, which includes a gas supply part, a hydrogen detection part, and an exhaust gas treatment part.

[0042]The air supply part includes an air tank 12, a hydrogen tank 13, a nitrogen tank 14, a drier 1 and an air storage chamber 3, wherein the air tank 12, the hydrogen tank 13, and the nitrogen tank 14 are connected to the drier through pipelines, and the drier is connected to the gas storage room. The air tank 12, the hydrogen tank 13 and the nitrogen tank 14 each have control valves, and the pipelines between the air tank 12, the hydrogen tank 13, the nitrogen tank 14 and the drier 1 are respectively provided with pressure reducing valves 15a, 15b, 15c and mass Flow controllers 16a, 16b, 16c; a heater 2 controlled by a temperature controller 17 is arranged in the air storage chamber; the dryer 1 in the air supply part is composed of 2mm wire mesh and coke desiccant with 4 upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com