Packaging structure and packaging method of module comprising bare chips of thin-film bulk acoustic wave device

A technology of thin-film bulk acoustic wave and packaging structure, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc. It can solve the problems of reducing packaging efficiency and unfavorable module miniaturization, so as to improve packaging efficiency, reduce volume, The effect of protecting the working surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

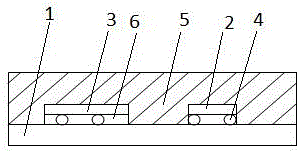

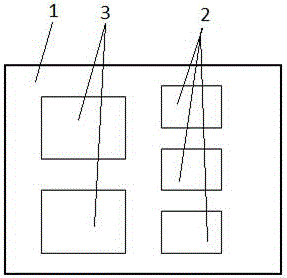

[0019] see figure 1 with figure 2 , it can be seen from the figure that the present invention includes a multi-chip module packaging structure including a bare chip of a thin film bulk acoustic wave device, including a (ceramic) substrate 1 and a bare chip, and the bare chip includes a bare chip of a thin film bulk acoustic wave device 2 ( figure 2 3 pieces shown) and other functional die 3 ( figure 2 2 pieces shown), with corresponding electrodes on the substrate and all die. All bare chip electrodes are correspondingly connected to the substrate electrodes by gold balls 4 through flip-chip welding, and a film layer 5 (the embodiment is an adhesive film and a resin film) is bonded and fixed on the surface of the substrate, and the film layer 5 is closely attached to the substrate 1 surface and wraps all bare chips simultaneously. All ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com