Gallium nitride-based inverted light-emitting diode (LED) with two reflecting layers on lateral surfaces and preparation method thereof

A light-emitting diode, gallium nitride-based technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of limited light reflectivity and low surface resistivity of the reflective layer, achieve excellent reflectivity, and improve the effect of light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0037] A method for preparing a gallium nitride-based flip-chip light-emitting diode with double reflective layers on its side, the steps of which are as follows:

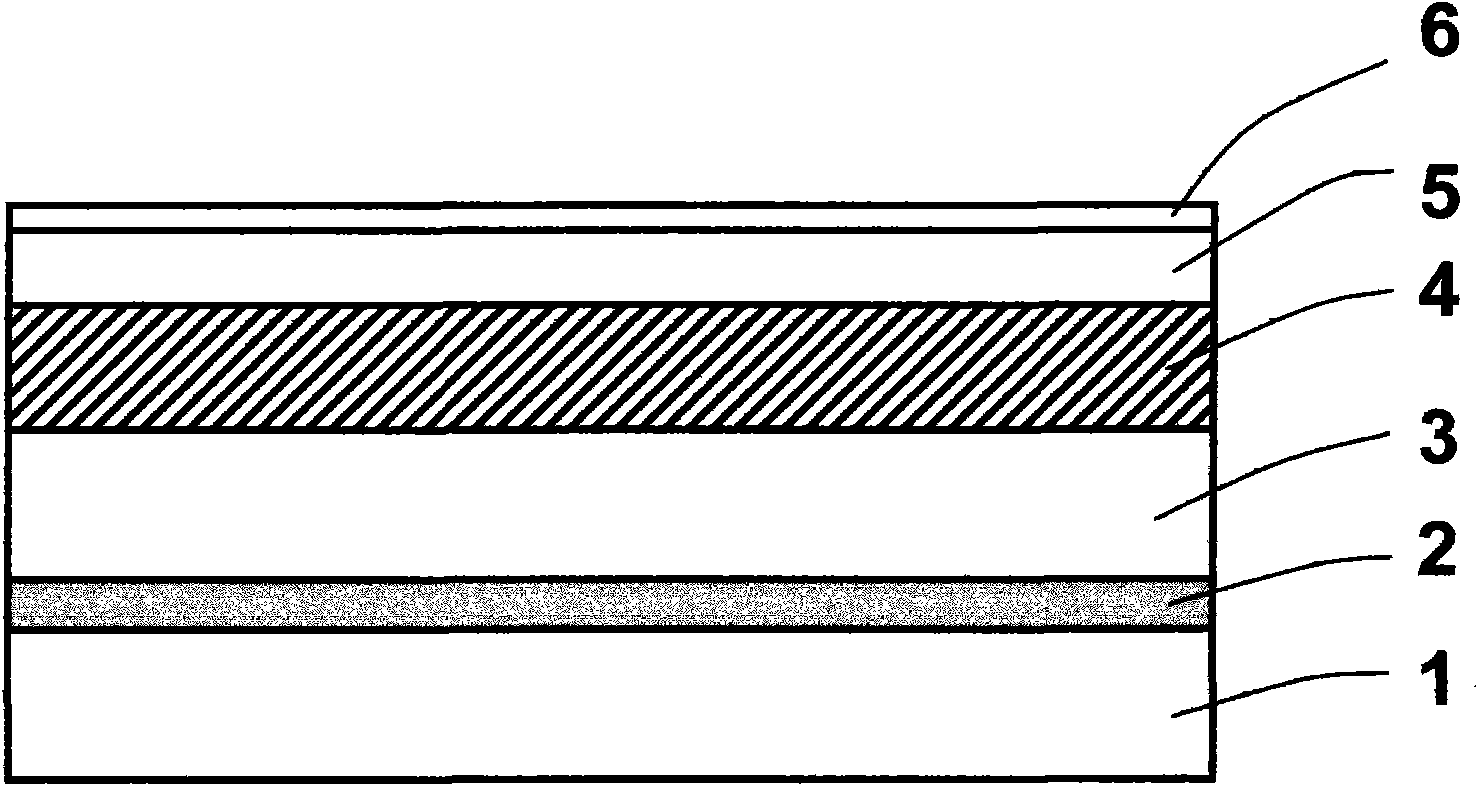

[0038] like figure 1 As shown, a buffer layer 2 and an epitaxial layer are sequentially grown on a sapphire substrate 1, wherein the epitaxial layer includes an N-GaN layer 3, a multi-quantum well layer 4 and a P-GaN layer 5; an ITO layer is formed on the P-GaN layer 5 Transparent conductive layer 6;

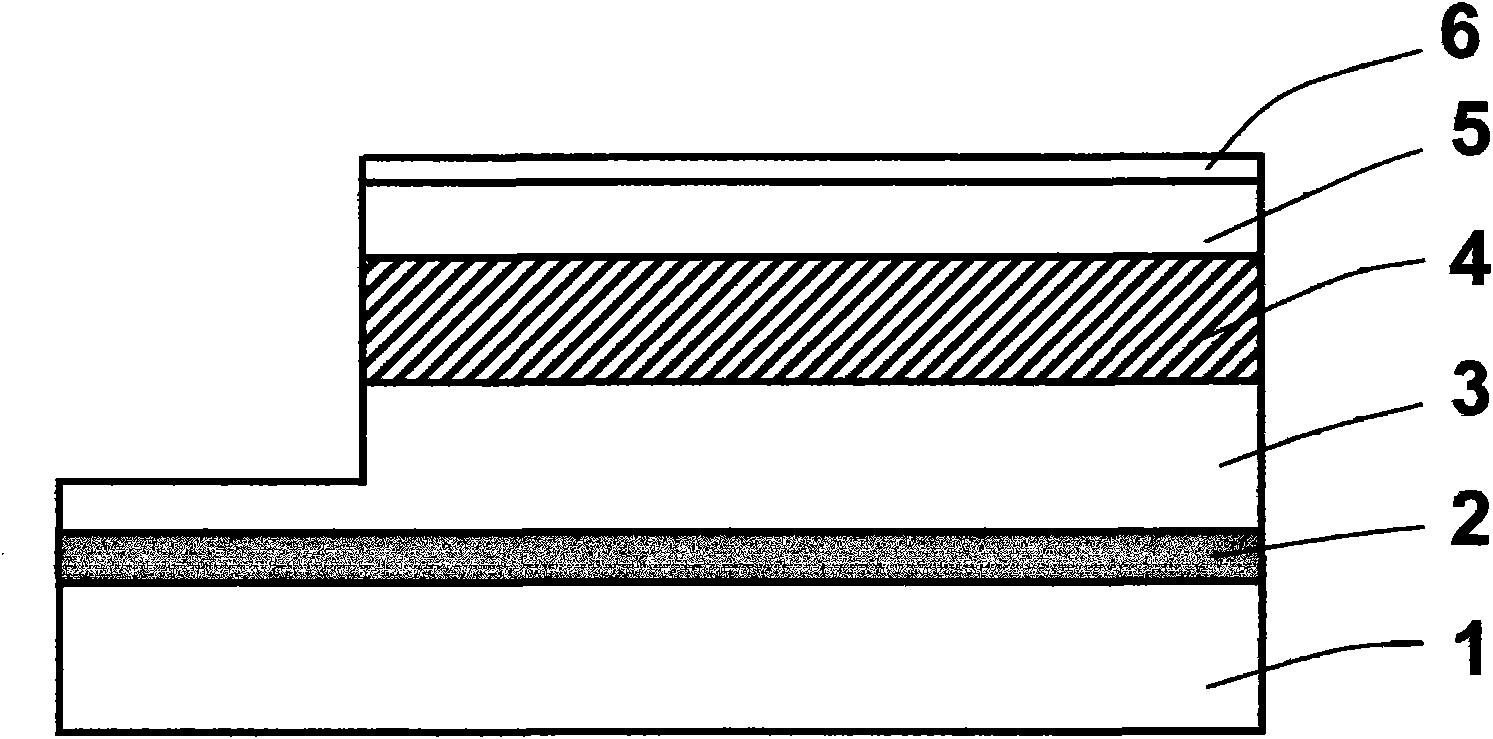

[0039] like figure 2 As shown, through a photomask and etching, the part of the mesa where the ITO transparent conductive layer 6 is located is etched to expose the N-GaN layer 3;

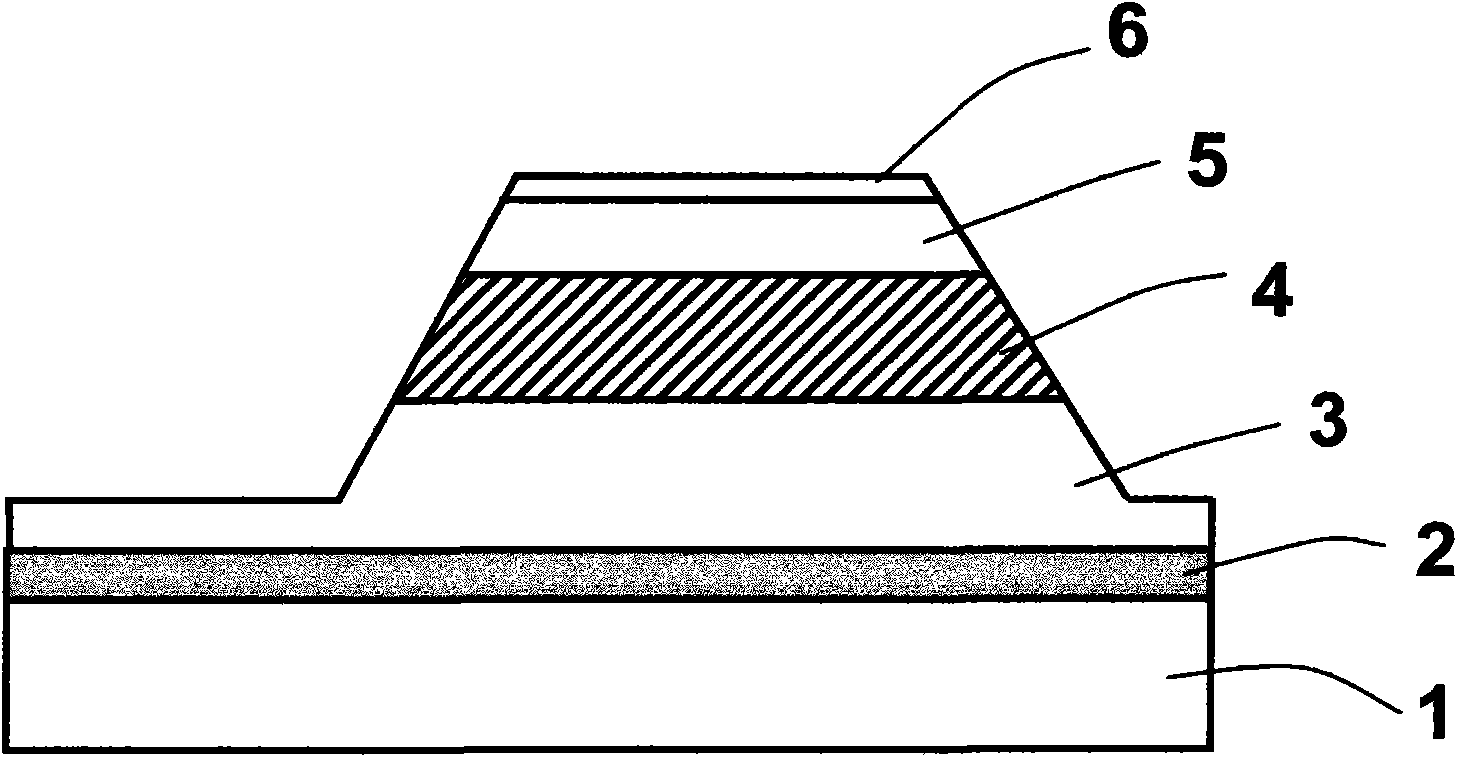

[0040] like image 3 As shown, by cutting, the sides of the epitaxial layer and the ITO transparent conductive layer 6 become inclined;

[0041] like Figure 4 As shown, the distributed Bragg reflection lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com