Spun gold ball welding machine, and device and method for adjusting welding spot position thereof

A technology for adjusting devices and solder joints, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as inability to ensure product quality consistency, high labor intensity for operators, and low welding efficiency, and achieve saving Training costs, consistency, and productivity gains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

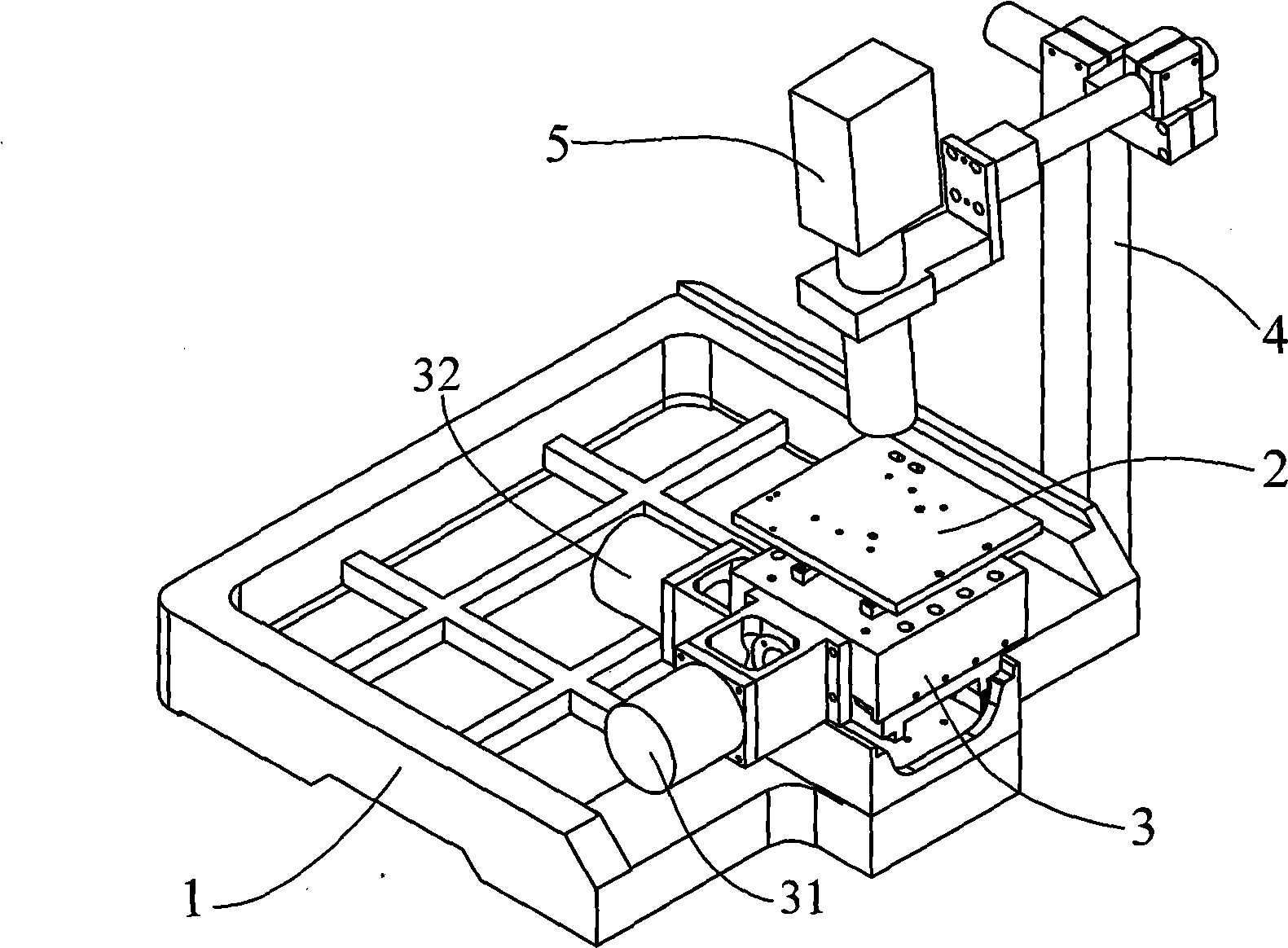

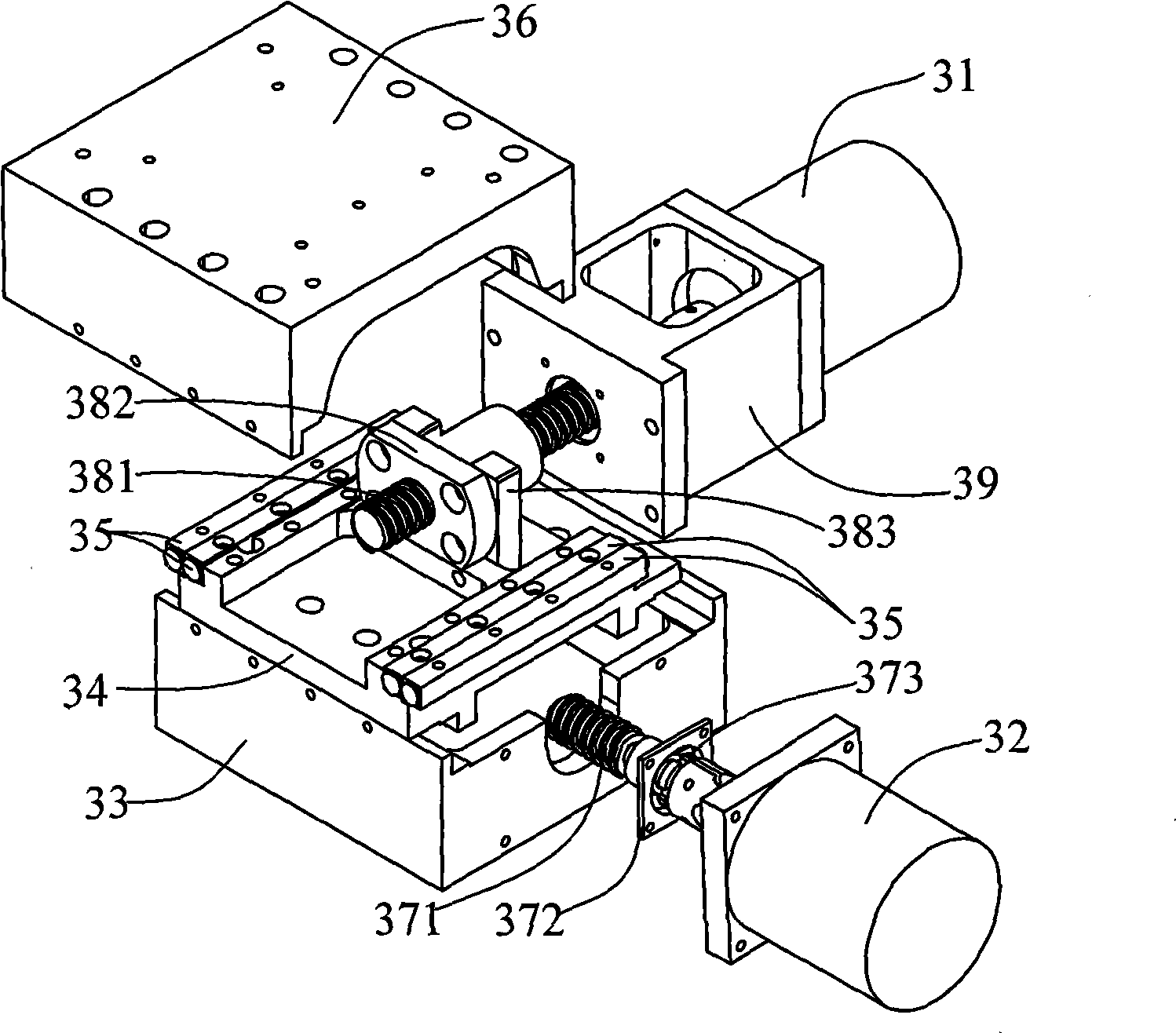

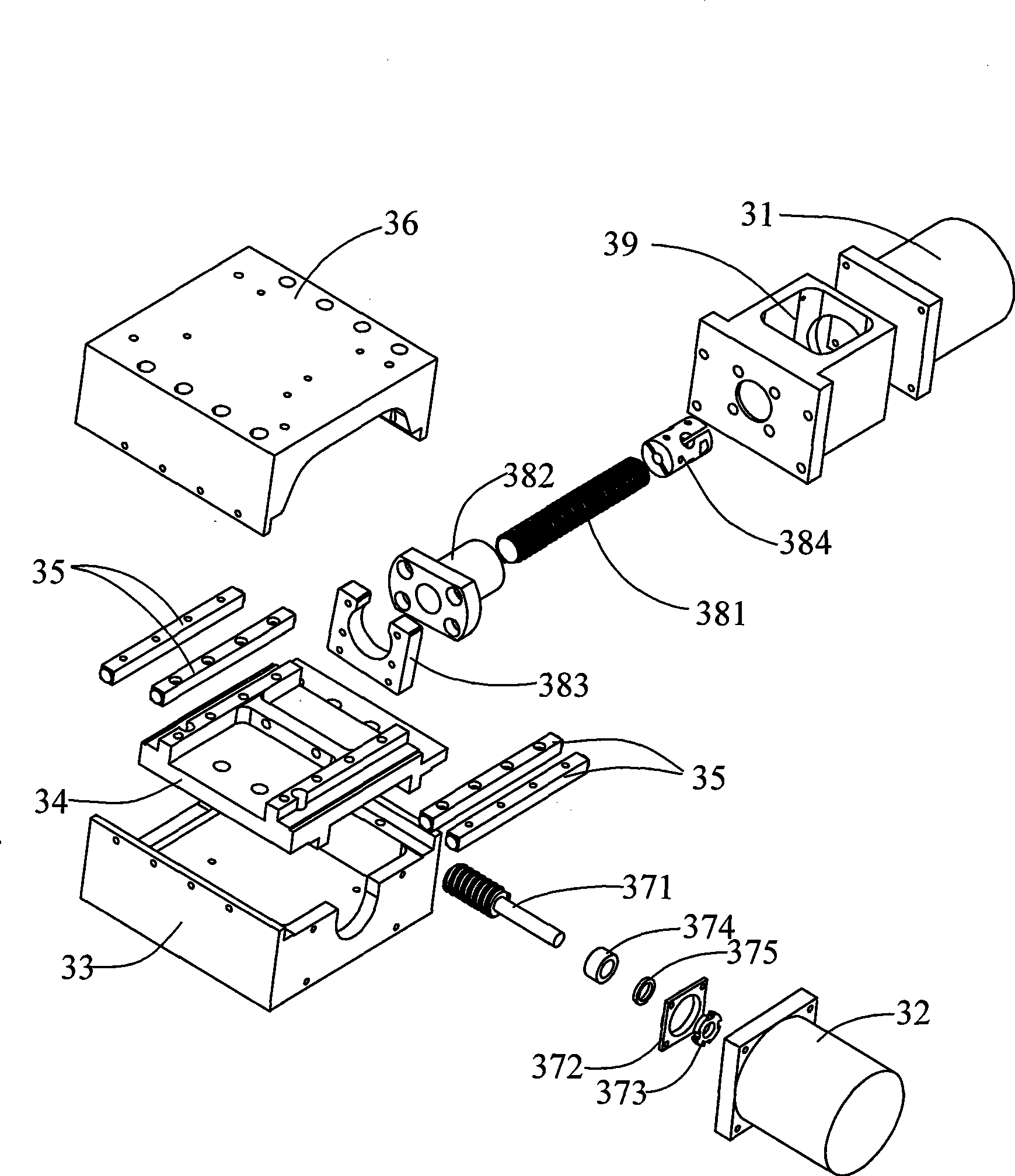

[0021] The gold wire ball welding machine of this specific embodiment is improved on the basis of the existing gold wire ball welding machine, especially the gold wire ball welding machine for welding light-emitting diode chips, mainly by canceling the existing gold wire The (stereo) microscope of the ball welding machine uses the computer to obtain the image information of the workpiece to be welded on the workbench through the camera connected to it, and then uses the software in the computer to identify the solder joints according to the pre-stored template, and then calculates The position deviation between the actual position of the solder joint and the position of the reference point (the orthographic projection position of the hacking knife on the workbench, that is, the set position of the solder joint), and finally the position adjustment is driven by a driver connected to the computer The corresponding stepping motor on the platform drives the workbench to fine-tune t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com