Preparation method of high performance conductive gold balls with monodispersity

A conductive gold ball, monodisperse technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of plating solution collapse, hydrolysis failure, microsphere agglomeration, etc., and achieve smooth surface gold layer. , the preparation method is simple, the reaction conditions are mild

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 6.3g of styrene, 1g of polyvinylpyrrolidone, 0.075g of azobisisobutyronitrile, 15g of ethanol, and 1.667g of water into a four-neck flask, stir evenly, and under nitrogen protection, polymerize at 65°C for 24 hours, centrifuge , alcohol washing, vacuum drying;

[0030] (2) Disperse the polymer microspheres in concentrated sulfuric acid at 80°C, treat them with stirring for 30 minutes, wash with water until neutral, add them to an aqueous solution of 0.02M polyethyleneimine (MW=20000) for surface modification, wash;

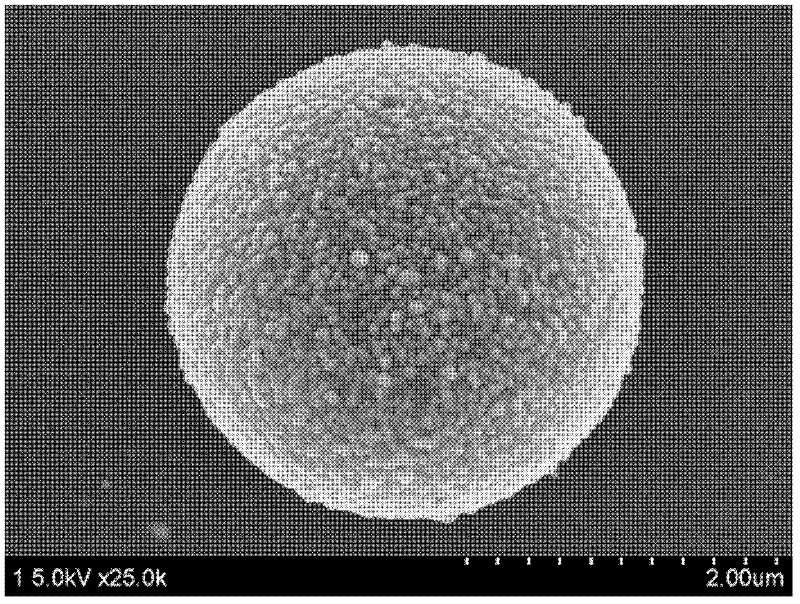

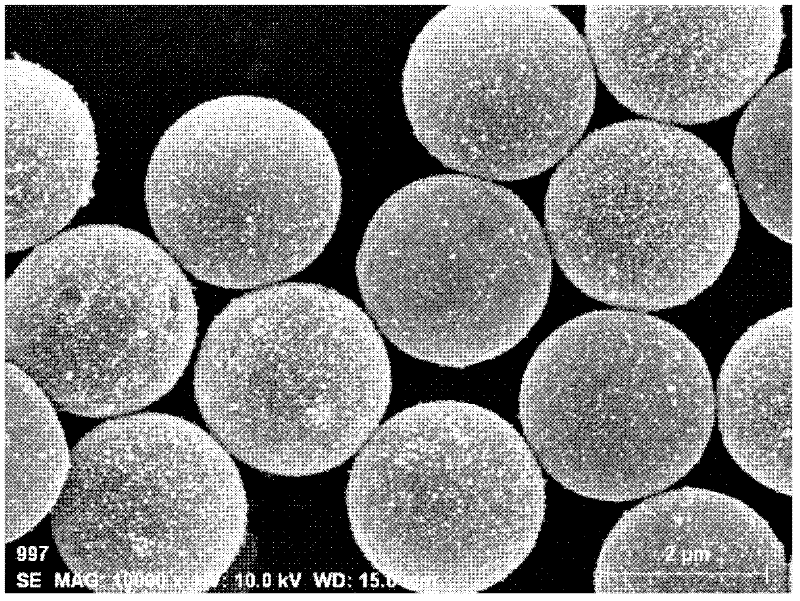

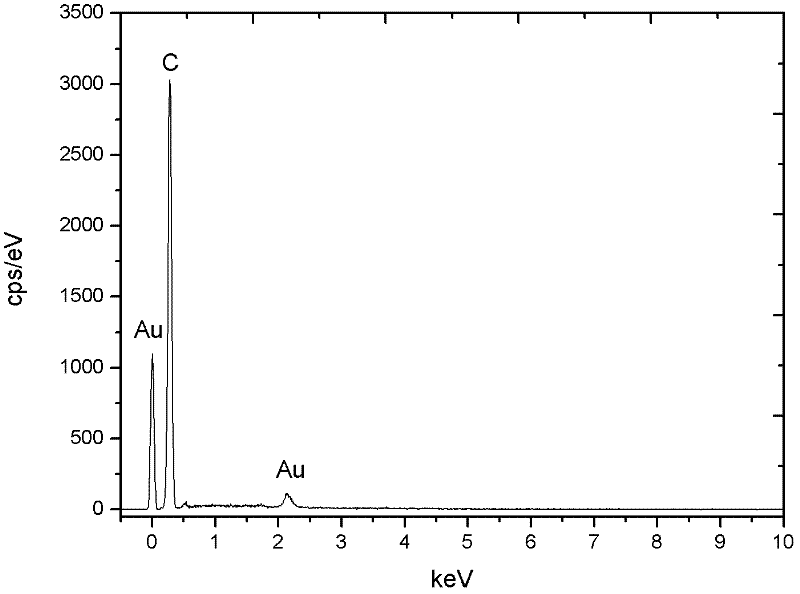

[0031] (3) Disperse the polymer microspheres in the negatively charged gold sol (dissolve 0.05mmol chloroauric acid, 0.1g polyvinylpyrrolidone, 0.1mmol sodium borohydride in 100mL water) and activate the reaction temperature at 20°C. After ultrasonic reaction for 20 minutes, wash with water, wash with alcohol, and dry in vacuum;

[0032] (4) polymer microspheres after the activation are finally dispersed in the chemical gold plating solution (the ...

Embodiment 2

[0035] (1) Add 6.3g of methyl methacrylate, 0.4g of polyvinylpyrrolidone, 0.25g of azobisisobutyronitrile, and 16g of ethanol into a four-neck flask, stir well, and under nitrogen protection, polymerize at 60°C for 24 hours, centrifuge , alcohol washing, vacuum drying;

[0036] (2) Disperse the polymer microspheres in chlorosulfonic acid at 20°C, treat them under stirring for 10 minutes, wash with water until neutral, and add them to an aqueous solution of 0.01M polyallyl ammonium chloride (MW=70000) to carry out Surface modification, water washing;

[0037] (3) Disperse the polymer microspheres in negatively charged gold sol (dissolve 0.05mmol chloroauric acid, 0.1g polyvinylpyrrolidone, 0.1mmol ascorbic acid in 100mL water) After 40 minutes, wash with water, wash with alcohol, and dry in vacuum;

[0038] (4) polymer microspheres after activation are finally dispersed in chemical gold plating solution (the composition of chemical plating solution: 1.5g / L chloroauric acid, 2...

Embodiment 3

[0040] (1) Add 5g of methyl methacrylate, 0.75g of polyacrylic acid, 0.075g of azobisisobutyronitrile, and 16g of methanol into a four-neck flask, stir evenly, and under nitrogen protection, polymerize at 70°C for 20h, centrifuge, ethanol washing, vacuum drying;

[0041] (2) Disperse the polymer microspheres in chlorosulfonic acid at 60°C, treat them with stirring for 90 minutes, wash with water until neutral, and add them to an aqueous solution of 0.02M polyethyleneimine (MW=20000) for surface modification , washed with water;

[0042] (3) Disperse the polymer microspheres in negatively charged gold sol (dissolve 0.05mmol chloroplatinic acid, 0.1g polyvinylpyrrolidone, 0.08mmol sodium borohydride in 100mL water) and activate the reaction temperature at 50°C. After ultrasonic reaction for 20 minutes, wash with water, wash with alcohol, and dry in vacuum;

[0043](4) polymer microspheres after activation are finally dispersed in chemical gold plating solution (the composition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com