Laminated secondary cell

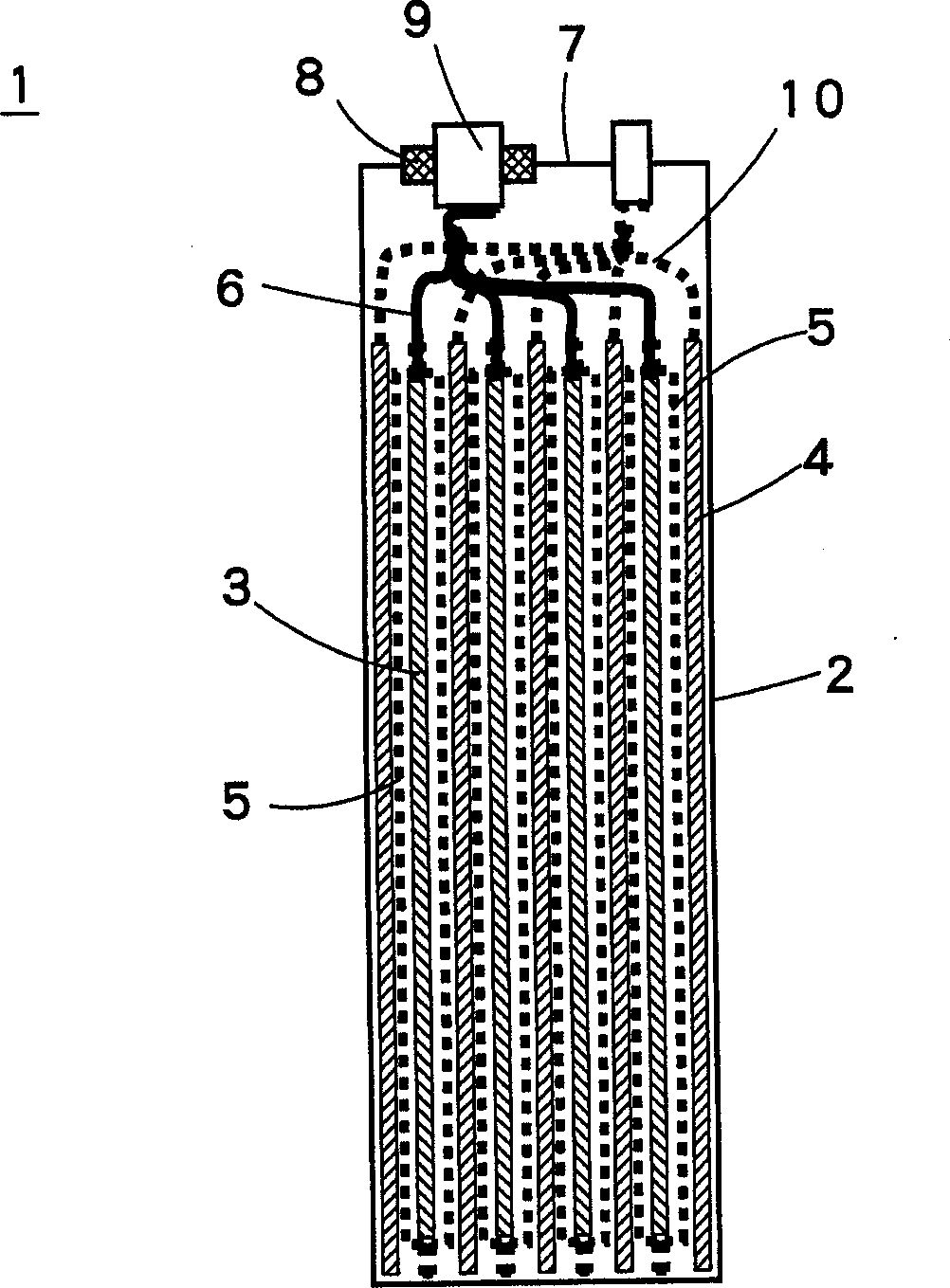

A secondary battery, laminated technology, applied in the direction of secondary batteries, secondary battery manufacturing, small flat batteries/batteries, etc., can solve problems such as increased assembly process, reduced battery active material, short circuit, etc., to achieve reliability big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

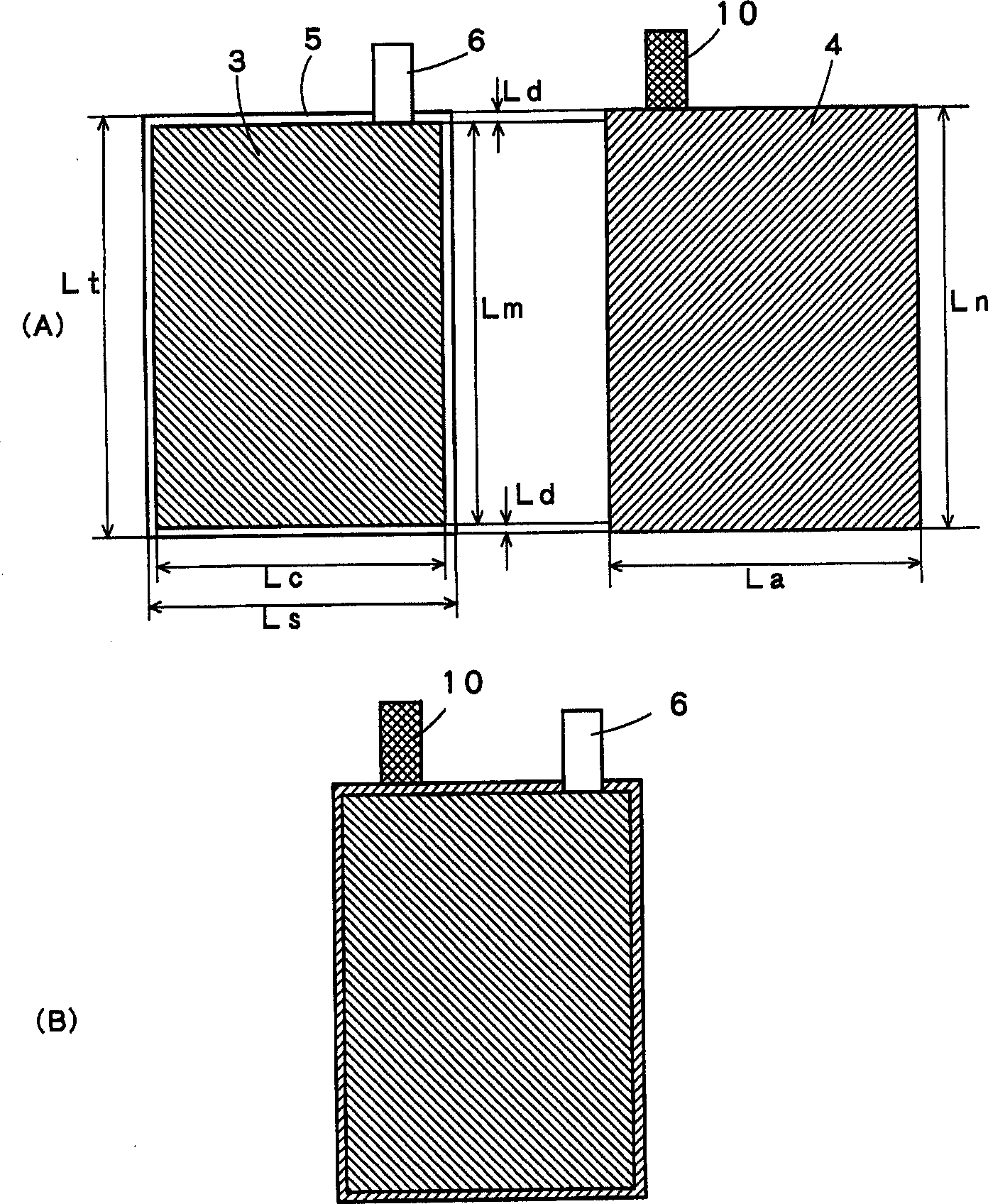

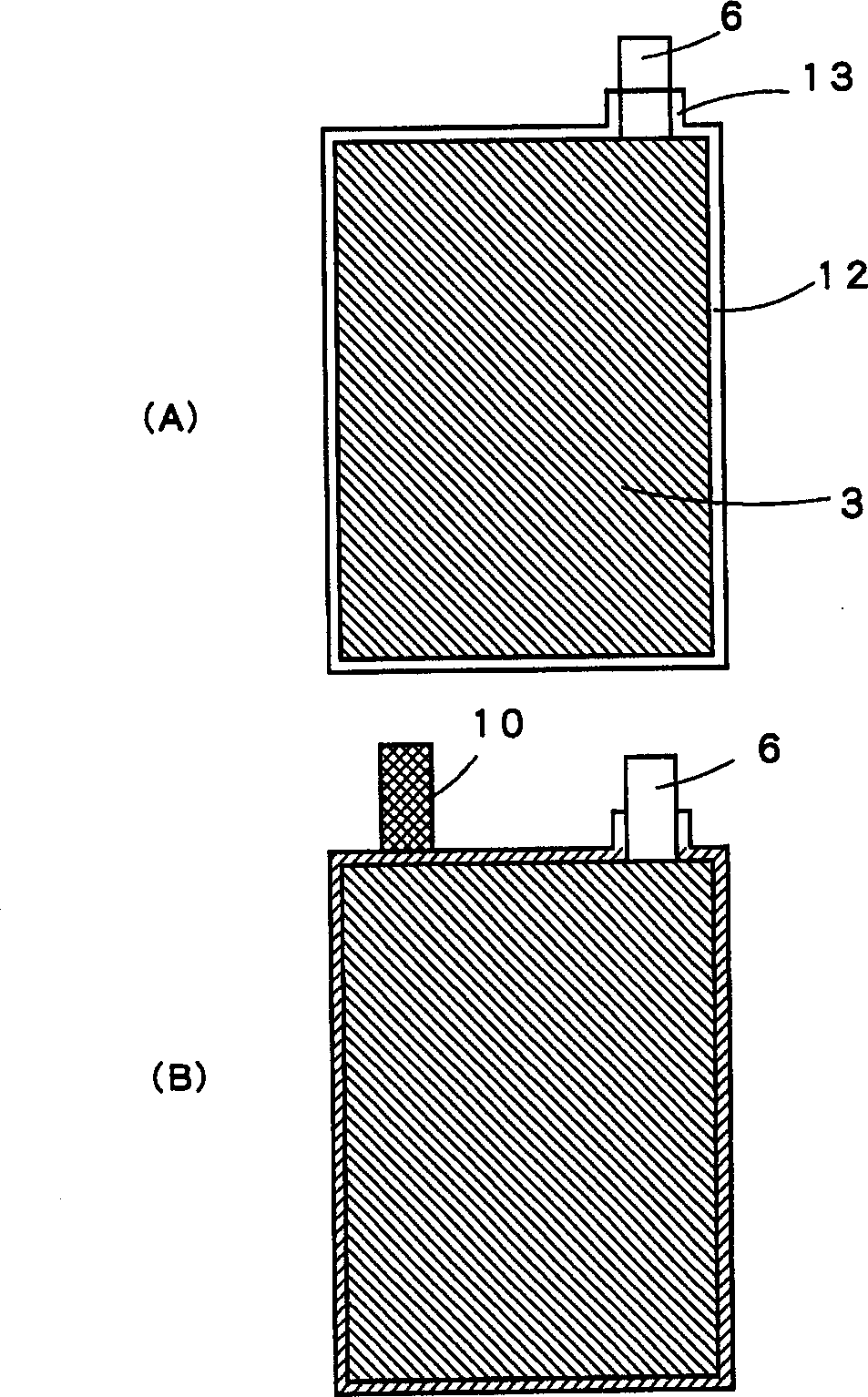

Embodiment 1

[0111] 92 parts by weight of lithium manganate (Li 1+x mn 2-x o 4 ) powder, 5 parts by weight of carbon black, the mixture of polyvinyl fluoride composition of 3 parts by weight, coating and drying on aluminum foil, after carrying out rolling compounding, the positive electrode that integrally forms positive electrode collector tab is long 120mm, wide 65mm, 200μm in thickness, 10mm in width of the positive electrode current collector tab, arrange separators of 125mm in length, 70mm in width, and 30μm in thickness on both sides of the positive electrode, and thermally weld their surroundings to make a separator cover positive electrode.

[0112] Furthermore, a mixture of 91 parts by weight of graphitized meso-carbon glass beads (MCMB manufactured by Osaka Gas), 1 part by weight of carbon black, and 8 parts by weight of polyvinyl fluoride was applied and dried on the copper foil. After rolling and compounding, a negative electrode integrally formed with the negative electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com