Preparation method of N-type crystalline silicon double-sided back contact solar cell

A technology of solar cells and crystalline silicon, applied in the field of solar cells, can solve problems such as hot spots, inability to diffuse in designated areas, and affect power generation and life of components, and achieve the effects of simple preparation process, good electrical performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

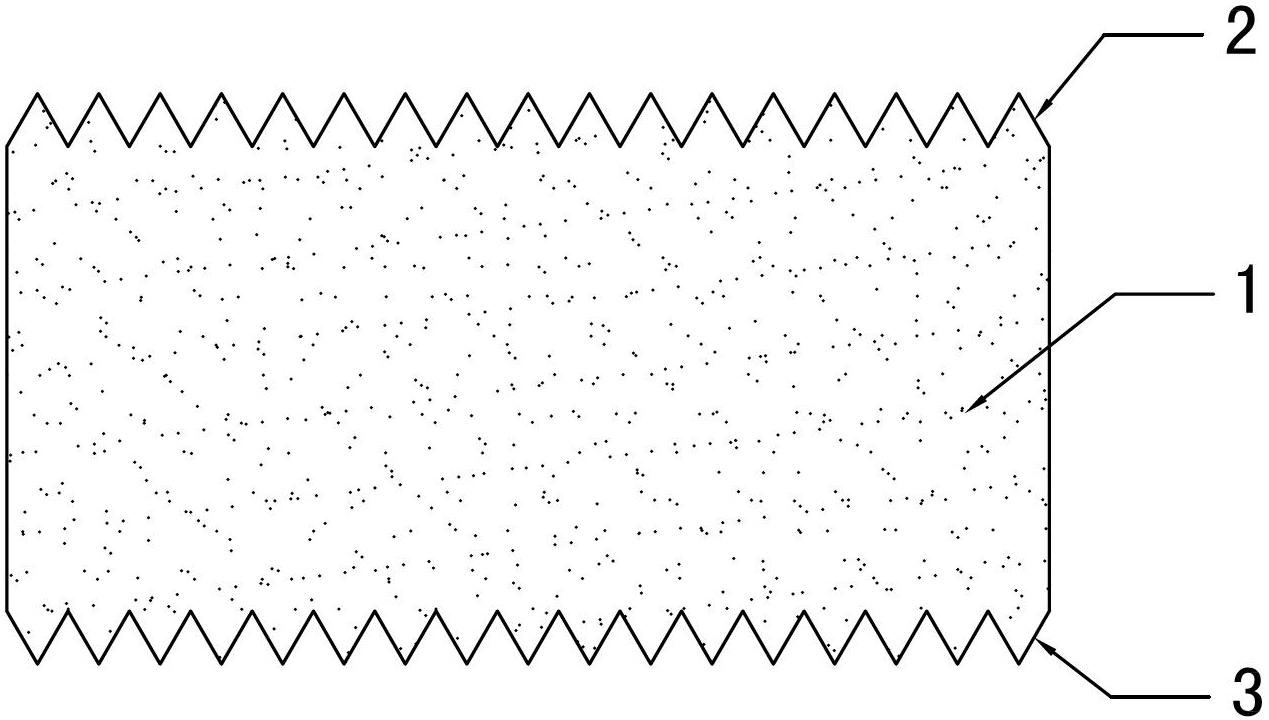

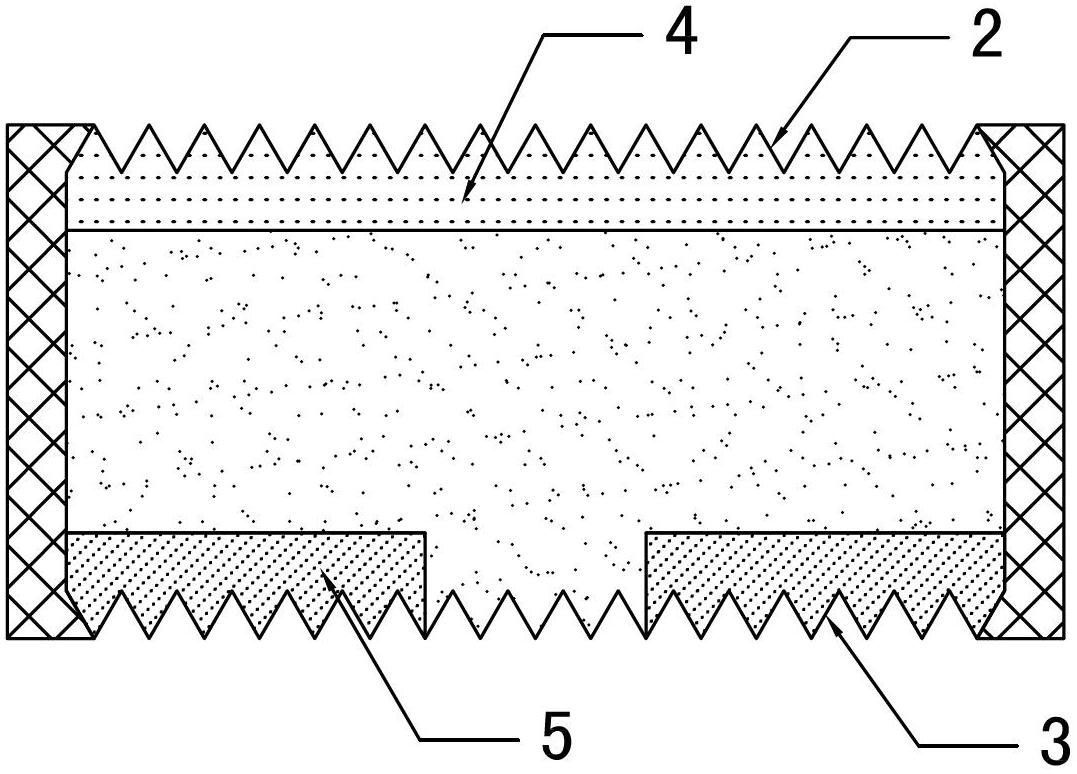

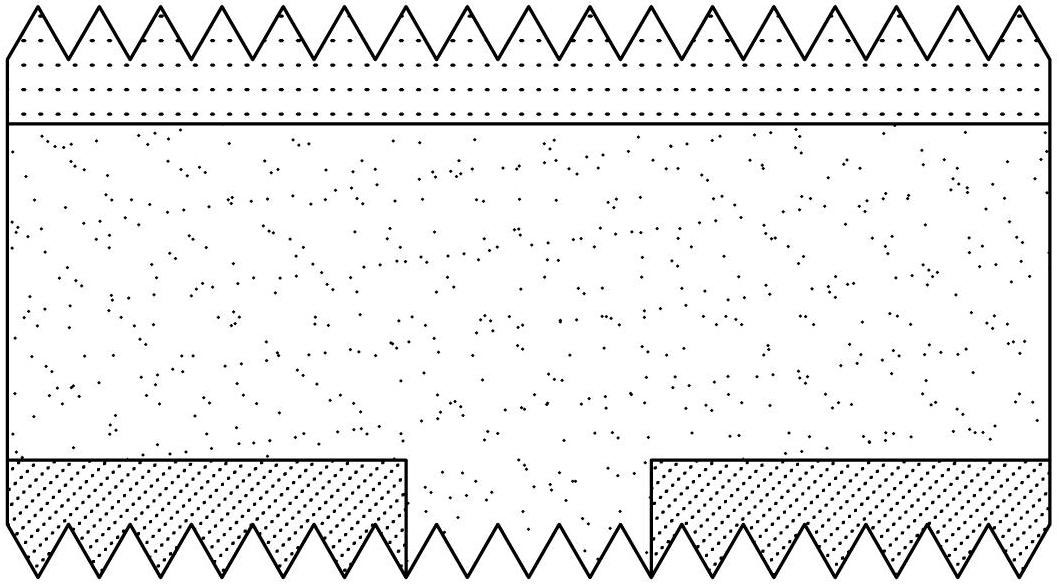

[0038] See Figure 1~7 As shown, a method for preparing an N-type crystalline silicon double-sided back contact solar cell includes the following steps:

[0039] Step S101: performing double-sided texturing on the N-type crystalline silicon wafer 1;

[0040] In the embodiment of the present invention, the contamination and damage layer on the surface of the N-type crystalline silicon wafer is chemically removed, and a suede structure is formed on both the front surface 2 and the back surface 3. The purpose is to reduce the reflection of incident light on the surface of the silicon wafer and increase The absorption of incident light by the silicon wafer; the structure diagram of the N-type crystal silicon wafer after texturing is as follows figure 1 Shown

[0041] Step S102: perform boron doping and local phosphorus doping on the front and back sides of the N-type silicon wafer, respectively;

[0042] By means of high temperature diffusion and other methods, boron doping on the front s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com